adn/al/m x o y Nano-based composite energetic material and preparation method

A nano-composite, nano-aluminum powder technology, applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve the problems of nanocomposite energetic materials, etc., to achieve strong operability, simple equipment, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Configure 30ml 0.1mol / L Fe(NO 3 ) 3 9H 2 O methanol solution, add 1g oxidant ammonium dinitramide (ADN) and stir until the solution is orange-red and transparent; add 0.5g nano-aluminum powder and 10ml 1,2-propylene oxide (PO) to the prepared solution . The color of the liquid gradually deepened, forming a reddish-brown wet gel. After standing and aging for 3 days, supercritical carbon dioxide drying was carried out at 45°C and 9.0MPa to obtain ADN / Al / Fe 2 o 3 Nanocomposite energetic materials.

Embodiment 2

[0034] Configure 30ml 0.2mol / L Al(NO 3 ) 3 9H 2 O to ethanol solution, add 2g oxidant ammonium dinitramide (ADN) and stir until the solution is transparent; add 1.0g nano-aluminum powder and 11ml 1,3-propylene oxide (TMO) to the prepared solution respectively. The color of the liquid gradually deepened, forming a reddish-brown wet gel. After standing and aging for 6 days, supercritical carbon dioxide drying was carried out at 46°C and 9.2MPa to obtain ADN / Al / Al 2 o 3 Nanocomposite energetic materials.

Embodiment 3

[0036] Configure 30ml 0.3mol / L Cu(NO 3 ) 2 ·6H 2 O to the ethylene glycol solution, add 3g oxidant ammonium dinitramide (ADN) and stir until the solution is transparent; add 1.5g nano-aluminum powder and 12ml 3,3-dimethyloxetane to the prepared solution Butane (DMO). The color of the liquid gradually deepened to form a reddish-brown wet gel. After standing and aging for 9 days, supercritical carbon dioxide drying was carried out at 47°C and 9.5MPa to obtain the ADN / Al / CuO nanocomposite energetic material.

PUM

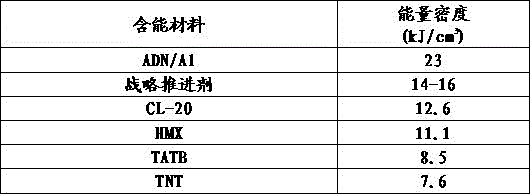

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com