Production method of pentaerythritol by virtue of potassium method

A pentaerythritol and production method technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problem of easy crystallization and precipitation of calcium formate to block equipment and pipelines, and the calcium method process is not mature and stable , affecting the quality of pentaerythritol products, etc., to achieve the effects of simple and feasible production methods, no pollution to the environment, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

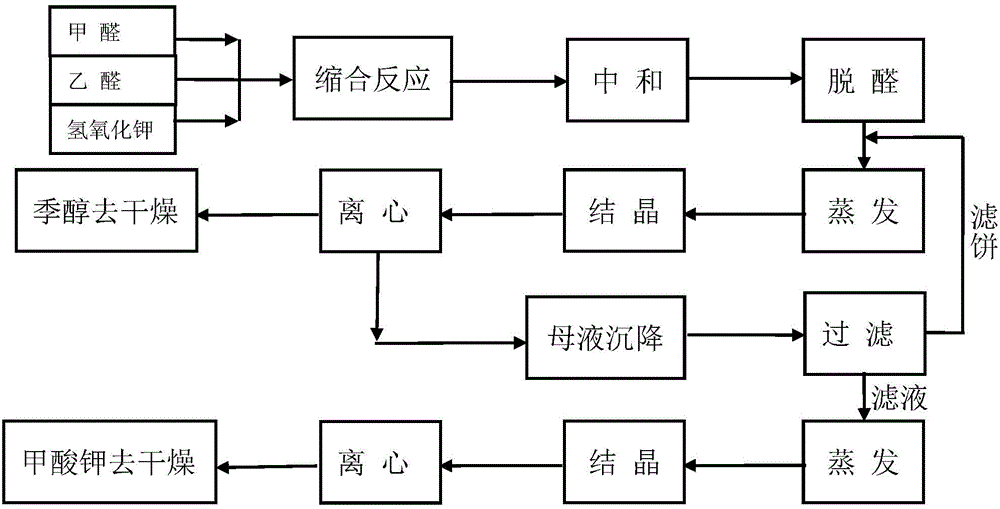

Image

Examples

Embodiment 1

[0020] The production method of potassium pentaerythritol includes the following steps in sequence:

[0021] A. The formaldehyde, acetaldehyde and potassium hydroxide are reacted according to the molar ratio of 6.0:1:1.3, the reaction temperature is 40°C, the reaction time is 2h, and the reaction solution is neutralized to pH=6.5 after the constant temperature for 1h;

[0022] B. Removal of excess formaldehyde in the materials obtained in step A and methanol produced by side reactions;

[0023] C. Concentrate the material obtained in step B to a solution specific gravity of 1.250g / ml, and then cool and crystallize for 6 hours;

[0024] D. Centrifuge, wash, and dry the material obtained in step C at 70°C to obtain 98 grade monopentaerythritol with a mass content of 98.5%, a platinum-cobalt chromaticity of 40, and an ash content of 0.02%. The yield is greater than 95%.

[0025] E. Return the filter cake obtained by sedimentation and filtration of the mother liquor obtained by centrifugati...

Embodiment 2

[0028] The production method of potassium pentaerythritol includes the following steps in sequence:

[0029] A. The formaldehyde, acetaldehyde and potassium hydroxide are reacted according to the molar ratio of 5.0:1:1.2, the reaction temperature is 60°C, the reaction time is 2h, and the reaction solution is neutralized to pH=6.5 after constant temperature for 1h;

[0030] B. Removal of excess formaldehyde in the materials obtained in step A and methanol produced by side reactions;

[0031] C. Concentrate the material obtained in step B to a solution specific gravity of 1.250g / ml, and then cool and crystallize for 8 hours;

[0032] D. Centrifuge, wash, and dry the material obtained in step C at 65°C to obtain 98-grade monopentaerythritol with a mass content of 98.3%, a platinum-cobalt chromaticity of 50, and an ash content of 0.03%, and the yield is greater than 95%;

[0033] E. Return the filter cake obtained by sedimentation and filtration of the mother liquor obtained by centrifugati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com