Environmental-friendly texture coating composition and preparation method thereof

A texture coating and composition technology, which is used in antifouling/underwater coatings, coatings, and biocide-containing paints, etc., can solve the problem of the sum of glycol ether and micester content, the excessive heavy metal content, and the inability to meet environmental protection requirements. and other problems, to achieve the effect of improved aging resistance and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment takes the preparation of 100kg water-based paint as an example, and its preparation method is as follows.

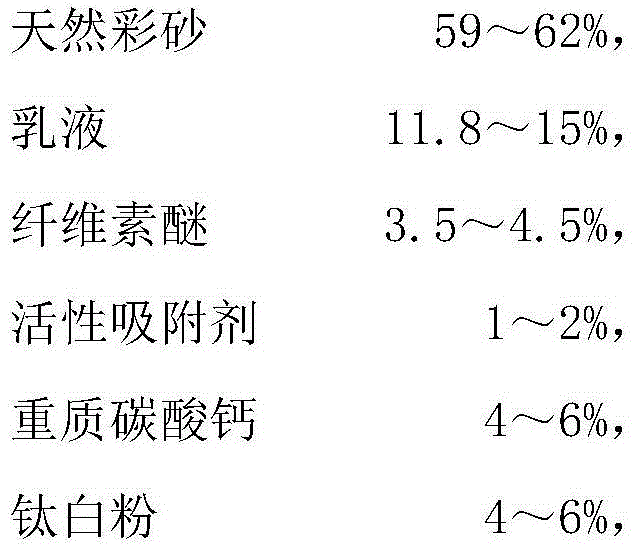

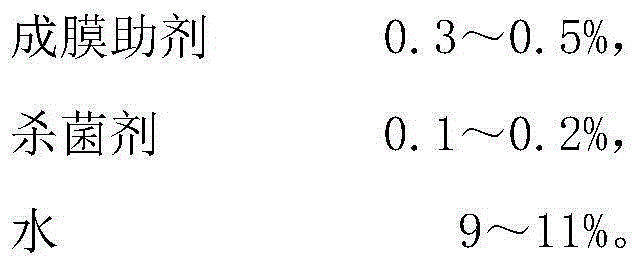

[0025] Weigh the ingredients according to the prescribed ratio, and the dosage (kg) of each raw material is as follows:

[0026]

[0027] The natural colored sand is 10-80 mesh; the emulsion is styrene-acrylic acid emulsion; the cellulose ether is hydroxypropyl methylcellulose ether (HPMC), the molecular weight is 10,000-50,000; the active adsorbent is activated clay, the mesh number 180-600 mesh; the particle size of heavy calcium carbonate is 1 μm; the film-forming aid is alcohol ester twelve; the fungicide is HY-6060 from Mayer Chemical.

[0028] The above-mentioned raw materials are weighed and prepared according to the proportion, and added and stirred according to the conventional paint process to obtain the water-based paint.

[0029] When using, it can be used according to the conventional texture paint construction process.

[0030] T...

Embodiment 2

[0035] This embodiment takes the preparation of 100kg water-based paint as an example, and its preparation method is as follows.

[0036] Weigh the ingredients according to the prescribed ratio, and the dosage of each raw material is as follows:

[0037]

[0038] The natural colored sand is 70-120 mesh; the emulsion is acrylate emulsion; the cellulose ether is hydroxypropyl methylcellulose ether, the molecular weight is 80,000-100,000; the active adsorbent is diatomite, the mesh number is 600-1100 mesh; the particle size of heavy calcium carbonate is 6 μm; the film-forming aid is alcohol ester twelve;

[0039] The above-mentioned raw materials are weighed and prepared according to the proportion, and added and stirred according to the conventional paint process to obtain the water-based paint.

[0040] The water-based paint prepared above has a volatile organic compound (VOC) content of ≤150g / L, a free formaldehyde content of ≤100mg / kg, a total content of glycol ether and ...

Embodiment 3

[0044] This embodiment takes the preparation of 100kg water-based paint as an example, and its preparation method is as follows.

[0045] Weigh the ingredients according to the prescribed ratio, and the dosage of each raw material is as follows:

[0046]

[0047] The natural colored sand is 110-180 mesh; the emulsion is styrene-acrylic acid emulsion and vinyl acetate-ethylene emulsion with a mass ratio of 1:1; the cellulose ether is hydroxypropyl methylcellulose ether (HPMC) with a molecular weight of 80,000 ~100,000; the active adsorbent is activated alumina, the mesh number is 1100-1500 mesh; the particle size of heavy calcium carbonate is 10μm; the film-forming aid is alcohol ester twelve; the fungicide is HY-6060 of Mayer Chemical .

[0048] The above-mentioned raw materials are weighed and prepared according to the proportion, and added and stirred according to the conventional paint process to obtain the water-based paint.

[0049]The water-based paint prepared abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com