High flame retardance spraying coating and preparation method thereof

A spray coating and high flame-retardant technology, which is applied in the field of high flame-retardant spray paint and its preparation, can solve the problems of material shrinkage, dimensional stability that cannot meet the use requirements, and high flame-retardant use requirements, etc., to achieve simple construction and synthesis The effect of simple process operation, environmental protection and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

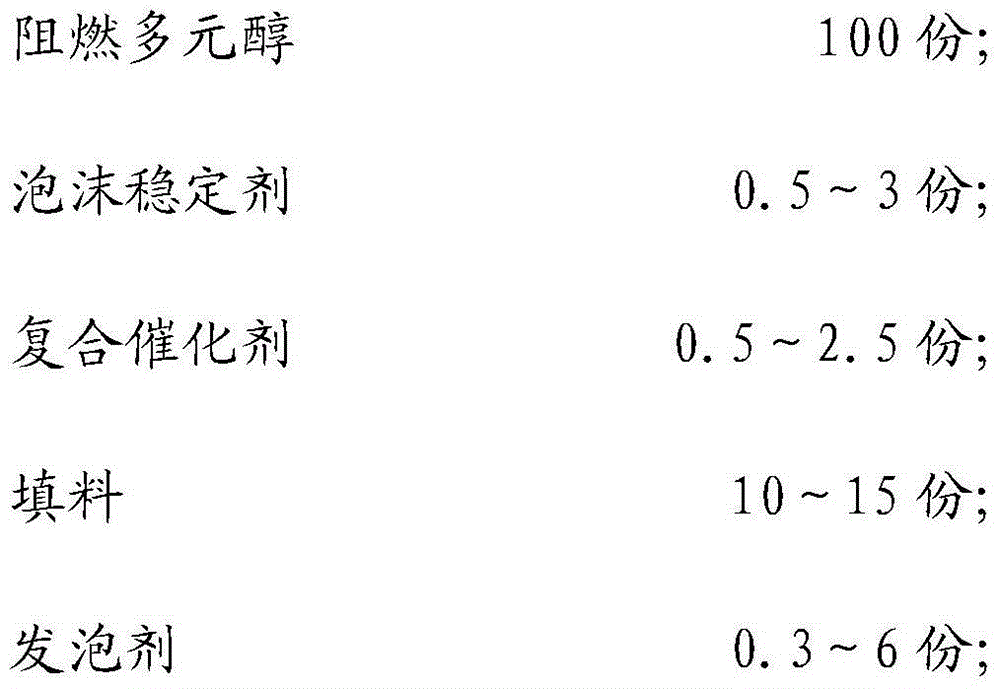

[0040] Raw material ratio

[0041]

[0042]

[0043] The raw materials of component B are proportioned according to the following parts by mass:

[0044] Diphenylmethane diisocyanate 306.6g

[0045] The preparation method is as follows:

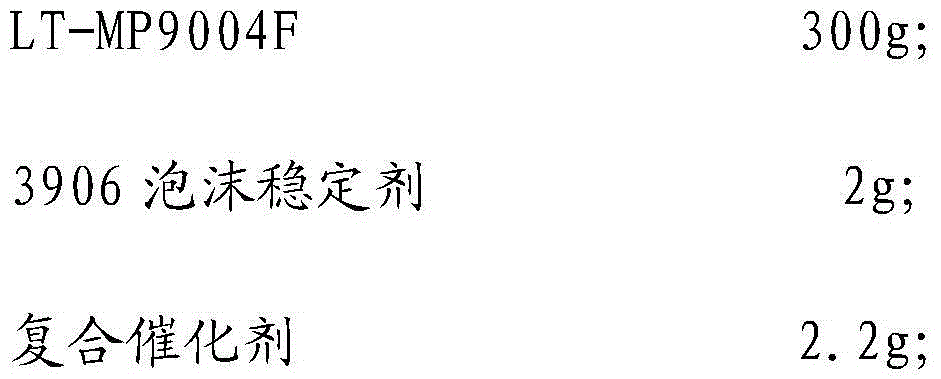

[0046] (1) Add 300g of LT-MP9004F and 2g of 3906 foam stabilizer into a three-necked flask, mix well, connect with a stirrer, and stir for 10-15 minutes at room temperature;

[0047] (2) Add 30 g of lithium silicate to the mixture obtained in step (1), heat to 80-100° C. and stir for 30-60 minutes;

[0048] (3) Add 2.2 g of composite catalyst (triethylenediamine: potassium isooctanoate: methylquaternary ammonium salt = 1:1:6) to the mixture obtained in step (2), and stir for 5 to 10 minutes to mix evenly;

[0049] (4) Add 2 g of purified water to the mixture obtained in step (3), and stir for 5-10 minutes to mix well.

[0050] (5) Add B-component diphenylmethane diisocyanate to the light-colored transparent liquid component A mixtur...

Embodiment 2

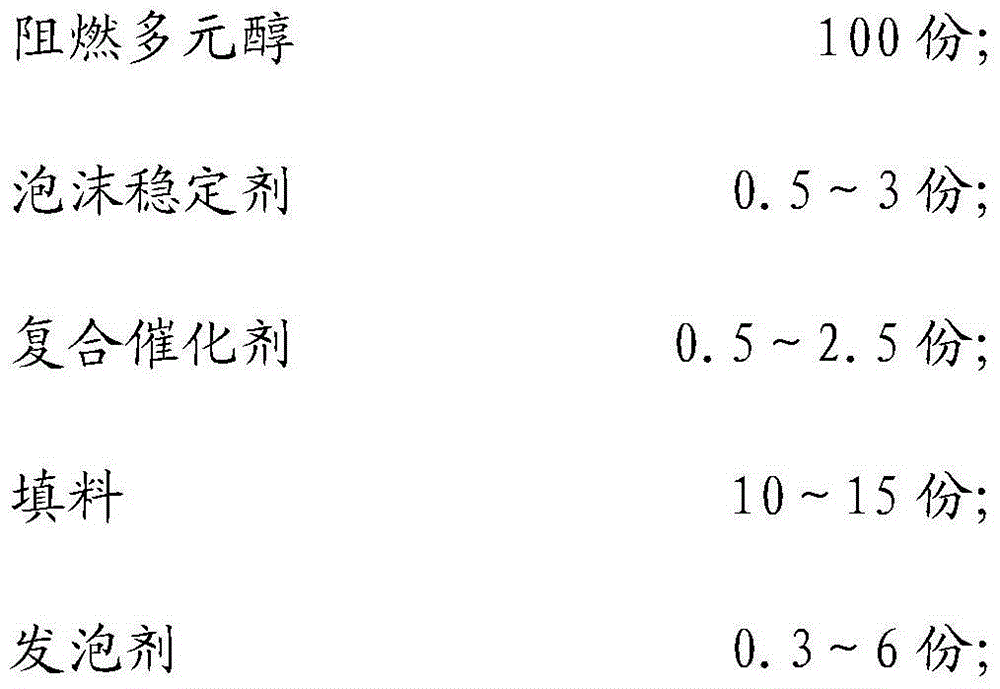

[0052] Raw material ratio

[0053]

[0054]

[0055] The raw materials of component B are proportioned according to the following parts by mass:

[0056] Diphenylmethane diisocyanate 274.8g

[0057] The preparation method is as follows:

[0058] (1) Add 300g of LT-MP9004F and 2.5g of 3303 foam stabilizer into a three-necked flask, mix well, connect to a stirrer, and stir for 10-15 minutes at room temperature;

[0059] (2) Add 35 g of calcium silicate to the mixture obtained in step (1), heat to 80-100° C. and stir for 30-60 minutes;

[0060] (3) Add composite catalyst 2.5g (N-ethylmorpholine: potassium oleate: methylquaternary ammonium salt = 1:2:8) to the mixture obtained in step (2), and stir for 5 to 10 minutes to mix evenly;

[0061] (4) Add 3.5 g of pure water to the mixture obtained in step (3), and stir for 5-10 minutes to mix well.

[0062] (5) Add B-component diphenylmethane diisocyanate to the light-colored transparent liquid component A mixture obtained in...

Embodiment 3

[0064] Raw material ratio

[0065]

[0066]

[0067] The raw materials of component B are proportioned according to the following parts by mass:

[0068] Diphenylmethane diisocyanate 373.92g

[0069] The preparation method is as follows:

[0070] (1) Add 300g of LT-MP9004F and 2.5g of 3906 foam stabilizer into a three-necked flask, mix well, connect to a stirrer, and stir for 10-15 minutes at room temperature;

[0071] (2) Add 45 g of magnesium silicate to the mixture obtained in step (1), heat to 80-100° C. and stir for 30-60 minutes;

[0072] (3) in the mixture that step (2) obtains, add composite catalyst 0.5g (dibutyltin dilaurate: potassium acetate: be dodecyl dimethyl benzyl ammonium chloride=1:2:9), and stir Mix well for 5-10 minutes;

[0073] (4) Add 1.6 g of purified water to the mixture obtained in step (3), and stir for 5-10 minutes to mix well.

[0074] (5) Add B-component diphenylmethane diisocyanate to the light-colored transparent liquid component A mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com