Emulsion mobility control agent and preparation method thereof

A technology of fluidity control agent and emulsion, which is applied in the field of emulsion fluidity control agent and its preparation, can solve the problems of poor compatibility, low temperature resistance and salt resistance, and achieve stable performance, strong regeneration ability and good long-term stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix the mass concentration of 30% coconut acid diethanolamide and 10% cocamidopropyl betaine into a high-temperature glass reaction kettle, heat up to 40°C, stir evenly at 200r / min, then add 9% ethanol Continue to stir for 30 minutes, then add 1% isopropanol, then slowly add the remaining amount of deionized water in batches, and stir evenly to obtain an emulsion fluidity control agent with an active substance content of 40% and a pH value of 7-9. The product It is yellow homogeneous liquid.

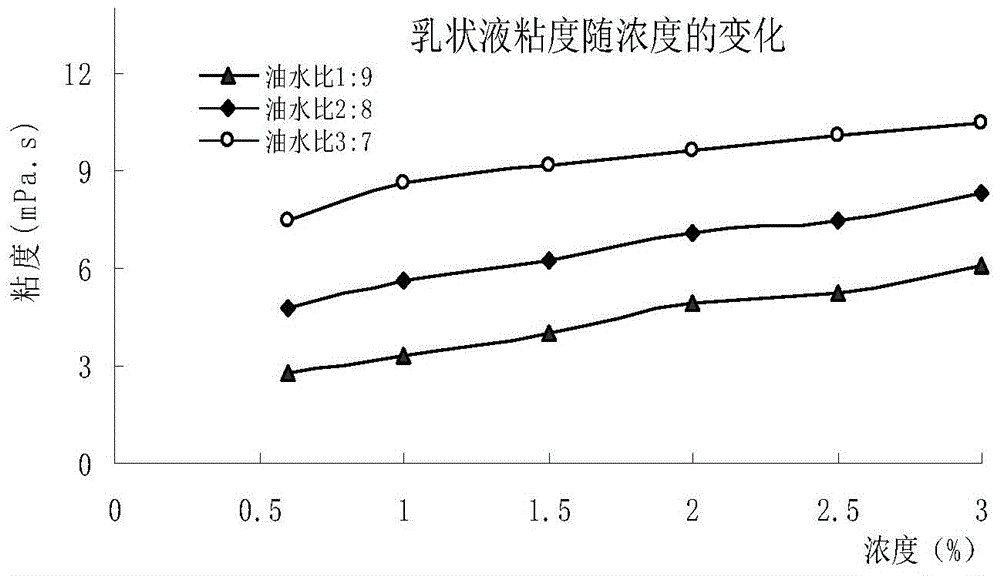

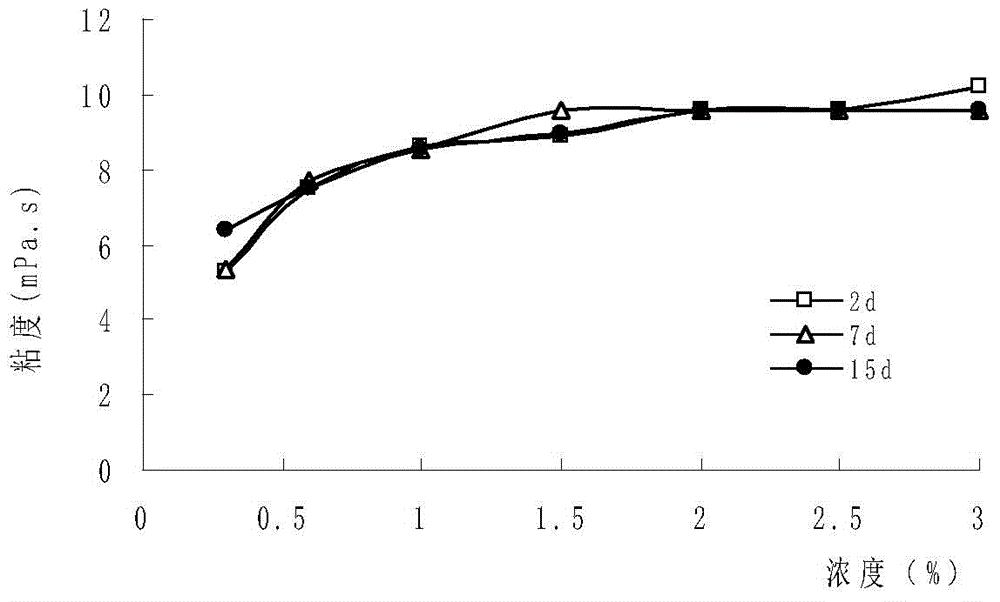

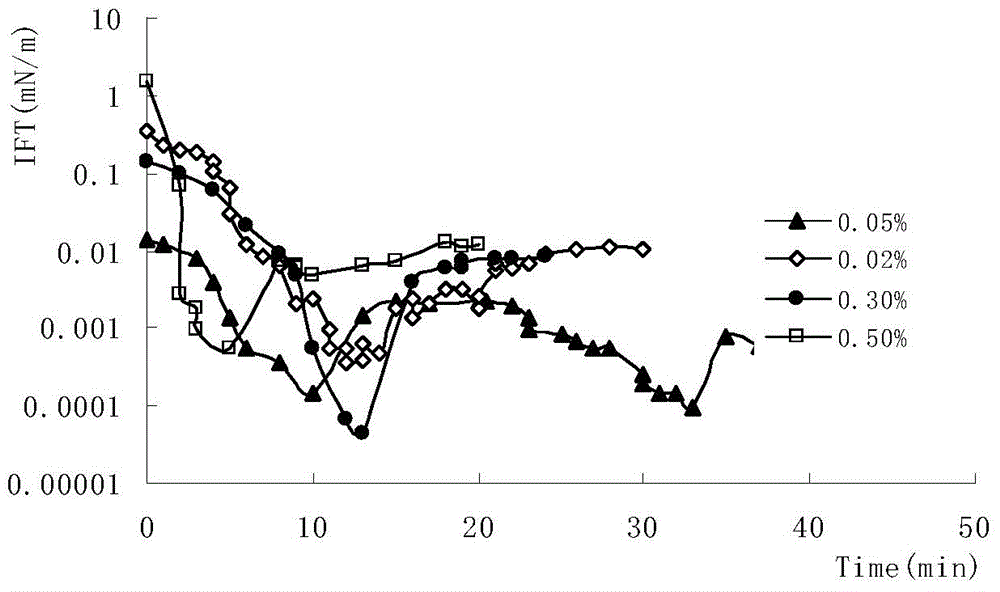

[0030] The total salinity of the emulsion fluidity control agent that embodiment 1 obtains is 18 * 10 4 mg / L Zhongyuan Pucheng oil field injection water, the total salinity is 20×10 4 mg / L of on-site produced water was prepared into a solution with a concentration of 0.6wt%-3wt% as the water phase, and the 2+3 crude oil on Shaer 2+3 in West Pucheng District was used as the oil phase. After mixing according to different oil-water ratios of 1:9 and 3:7, the airtight Put it in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com