Quenching oil extraction visbreaking system

A technology for quenching oil and extracting towers, which is applied in the treatment of hydrocarbon oils, refined hydrocarbon oils, and the petroleum industry. Scale and clogging, reduction of aggregation tendency, and improvement of separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

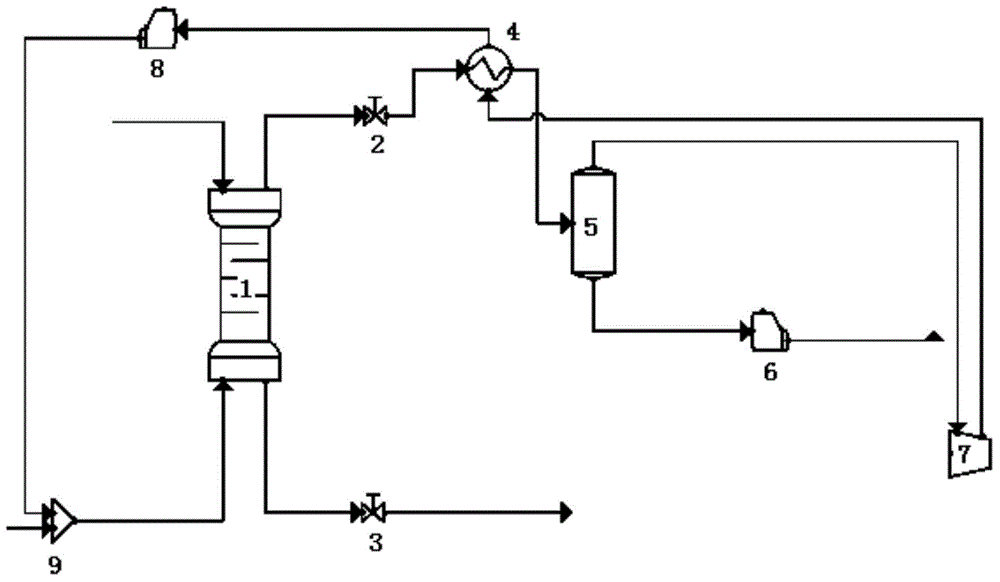

[0035]A quenching oil extraction viscosity reduction system, comprising: an extraction tower and a solvent recovery tower, the extraction tower is provided with a quenching oil feed port and a solvent feed port, the top of the extraction tower is connected to the middle of the solvent recovery tower, and the solvent recovery tower The top is connected to the solvent feed port of the extraction tower;

[0036] The number of extraction trays is 11, and the number of theoretical trays is 2. The trays are large-pore sieve trays with an opening ratio of 18% and a diameter of φ24mm. The quenching oil inlet is on the first tray, and the solvent inlet is on the Below the 11th tray.

[0037] Using propane as solvent, the quench oil is subjected to solvent extraction and viscosity reduction treatment. The feed temperature of quenching oil is 70°C, the pressure is 5MPa, and the flow rate is 10t / h. The solvent feed temperature is 70°C, the pressure is 5MPa, and the flow rate is 10t / h. ...

Embodiment 2

[0040] The number of extraction trays in the quenching oil visbreaking system of the ethylene plant is 22, and the number of theoretical trays is 4. The trays are large-pore sieve trays with an opening ratio of 15% and a diameter of φ20mm. The quenching oil inlet is on the first tray Above, the solvent feed port is below the 24th tray.

[0041] Using n-butane as solvent, the quench oil is subjected to solvent extraction and viscosity reduction treatment. The feed temperature of quenching oil is 150°C, the pressure is 5MPa, and the flow rate is 10t / h. The solvent feed temperature is 150°C, the pressure is 5MPa, and the flow rate is 50t / h. The temperature of the extraction tower is 150°C and the pressure is 5MPa. The extraction oil is separated from the top of the extraction tower, and the raffinate is separated from the bottom of the tower. The asphalt phase is decompressed to 1MPa atmospheric pressure to remove the solvent, and then it is recovered as fuel oil.

[0042] Re...

Embodiment 3

[0044] The lower part of the extraction tower of the quenching oil visbreaking system of the ethylene plant is a large-pore sieve plate with an opening ratio of 12% and a diameter of φ18mm, with 11 plates and a theoretical plate number of 2; the upper part is a 2m high wire mesh packing with a theoretical plate number of 8 . The number of theoretical plates in the whole tower is 10, the large-pore sieve plate accounts for 20%, and the wire mesh packing accounts for 80%. The inlet for quenching oil is above the screen packing, and the inlet for solvent is under the 11th large-pore sieve tray.

[0045] Using n-butane as solvent, the quench oil is subjected to solvent extraction and viscosity reduction treatment. The feed temperature of quenching oil is 180°C, the pressure is 5MPa, and the flow rate is 10t / h. The solvent feed temperature is 180°C, the pressure is 5MPa, and the flow rate is 50t / h. The temperature of the extraction tower is 180°C and the pressure is 5MPa. The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com