Additive for reducing sulfur dioxide discharge of alcohol-based fuel

A technology of alcohol-based fuel and sulfur dioxide, which is applied in the field of additives for alcohol-based fuels and additives for reducing sulfur dioxide emissions from alcohol-based fuels. The preparation process is simple, the effect of avoiding secondary pollution and widely promoting the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 11kg of 1-hexylpiperidin-4-ol, 24kg of N-hexyl-N-vinylformamide, 19kg of cis-3-hexenol 2-methylbutyrate, 1,5-hexadiene-3 , 16kg of 4-diol, 14kg of 1-methylhexahydro-4H-azepine-4-one and 16kg of lithium acetoacetate were added to the stirring tank, and stirred evenly at room temperature to obtain transparent and clear alcohol-based fuel sulfur dioxide reduction Emission of finished additives.

[0018] Add 4kg of the additive of this example to 900kg of crude alcohol, mix evenly, and treat it with a BMT-180 ultrasonic instrument of BRANSON in the United States for 20 minutes at room temperature, then add 96kg of conventional additives for other alcohol-based fuels to obtain an alcohol-based fuel.

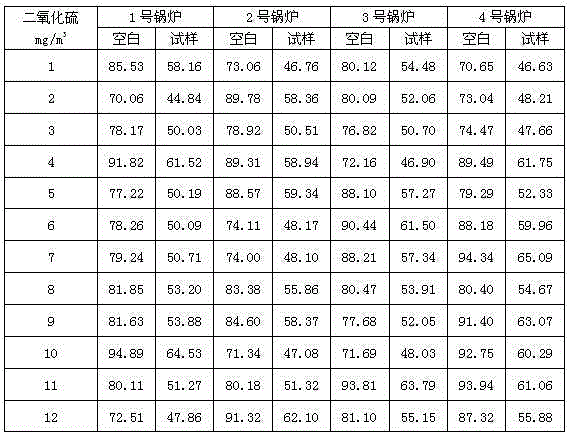

[0019] Twelve kinds of crude alcohols from all over the country were selected as basic raw materials to prepare two groups of 24 alcohol-based fuel samples. Among them, the first group is a blank control group that uses 12 kinds of crude alcohol raw materials without addi...

Embodiment 2

[0024] Take 16kg of 1-hexylpiperidin-4-ol, 15kg of N-hexyl-N-vinylformamide, 17.5kg of cis-3-hexenol 2-methylbutyrate, 1,5-hexadiene- Add 15.5kg of 3,4-diol, 20kg of 1-methylhexahydro-4H-azepine-4-one and 16kg of lithium acetoacetate into the stirring tank, and stir evenly at room temperature to obtain transparent and clear alcohol-reduced Finished additives for fuel sulfur dioxide emissions.

[0025] Add 4kg of the additive of this example to 800kg of crude alcohol, mix evenly, and treat it with the BMT-180 ultrasonic instrument of BRANSON in the United States for 20 minutes at room temperature, and then add 196kg of conventional additives for other alcohol-based fuels to obtain alcohol-based fuel.

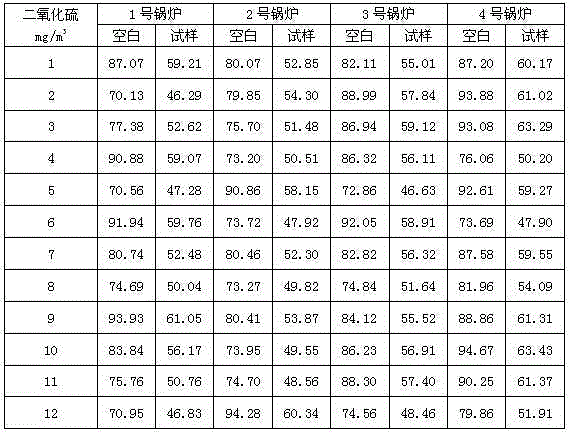

[0026] Carry out test according to embodiment 1 method, detection result is as follows.

[0027]

Embodiment 3

[0029] Take 21kg of 1-hexylpiperidin-4-ol, 16kg of N-hexyl-N-vinylformamide, 15kg of cis-3-hexenol 2-methylbutyrate, 1,5-hexadiene-3 , 12kg of 4-diol, 16kg of 1-methylhexahydro-4H-azepine-4-one and 20kg of lithium acetoacetate were added to the stirring tank, and stirred evenly at room temperature to obtain transparent and clear alcohol-based fuel sulfur dioxide reduction Emission of finished additives.

[0030] Add 4kg of the additive of this example to 950kg of crude alcohol, mix evenly, and treat it with a BMT-180 ultrasonic instrument of BRANSON, USA for 20 minutes at room temperature, then add 46kg of conventional additives for other alcohol-based fuels to obtain alcohol-based fuel.

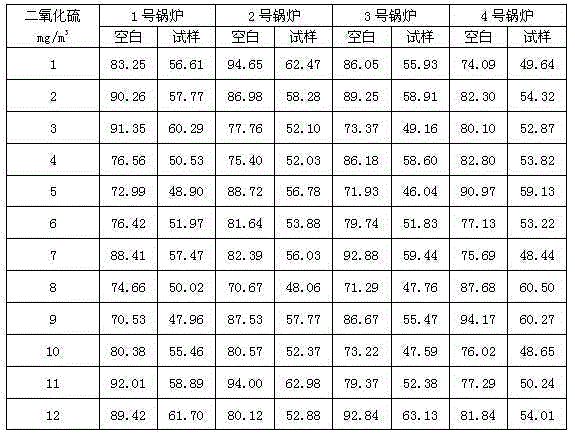

[0031] Carry out test according to embodiment 1 method, detection result is as follows.

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com