Method for rapid preparation of grapheme/silver sulfide quantum dot nanocomposite and product

A nanocomposite material and graphene technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor product quality and cumbersome preparation process, and achieve low energy consumption and high application prospects Broad range of effects with mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

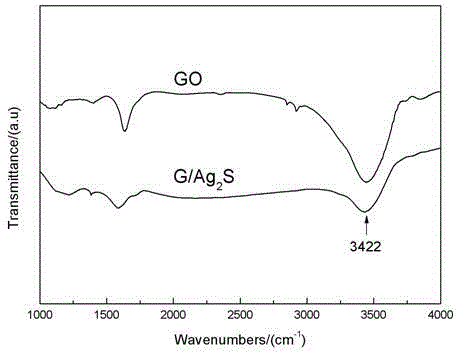

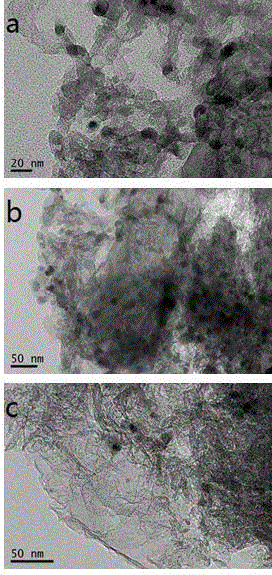

[0027] Graphene oxide (40 mg) and AgNO 3 (67.5 mg) was dispersed in dimethyl sulfoxide solution (50 mL). After vigorous stirring, the solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave and reacted at 180 °C for 12 h. The obtained solution was intensively rinsed with acetone, and then cleaned with alcohol in an ultrasonic cleaner to remove unreacted reactants and silver sulfide quantum dots not bound to the graphene sheet. The product was centrifuged at 4000 rpm and then dried in a vacuum desiccator. The composite material prepared in the experiment has a good and stable single-layer structure with good stability, and the particle size of the loaded silver sulfide quantum dots is about 10 nm. The infrared spectrograms of the prepared graphene oxide and graphene / silver sulfide quantum dot nanocomposites are shown in figure 1 . It can be observed from the figure that the O-H stretching vibration absorption peak of the graphene / silver sulfide...

Embodiment 2

[0029] Graphene oxide (40 mg) and AgNO 3 (67.5 mg) was dispersed into dimethyl sulfoxide solution (50 mL). After vigorous stirring, the solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave and reacted at 180 °C for 15 h. The obtained solution was intensively rinsed with acetone, and then cleaned with alcohol in an ultrasonic cleaner to remove unreacted reactants and silver sulfide quantum dots not bound to the graphene sheet. The product was centrifuged at 4000 rpm and then dried in a vacuum desiccator. The composite material prepared in the experiment has a good and stable single-layer structure with good stability, and the particle size of the loaded silver sulfide quantum dots is about 12 nm.

Embodiment 3

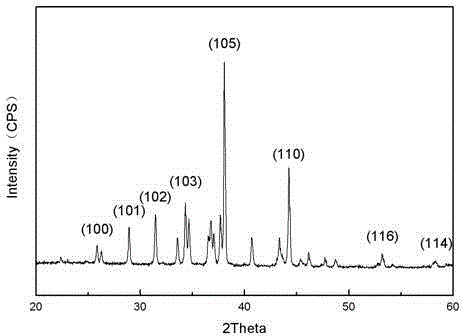

[0031] Graphene oxide (40 mg) and AgNO 3 (67.5 mg) was dispersed into dimethyl sulfoxide solution (50 mL). After vigorous stirring, the solution was transferred to a Teflon-lined stainless steel autoclave at 160 °C for 10 h. The obtained solution was intensively rinsed with acetone, and then cleaned with alcohol in an ultrasonic cleaner to remove unreacted reactants and silver sulfide quantum dots not bound to the graphene sheet. The product was centrifuged at 4000 rpm and then dried in a vacuum desiccator. The composite material prepared in the experiment has a good and stable single-layer structure with good stability, and the particle size of the loaded silver sulfide quantum dots is about 8 nm. The graphene and the graphene / silver sulfide quantum dot nanocomposite material fluorescence spectrum contrast graph that prepares are shown in image 3. From the curve (b) in the figure, it can be seen that the pure graphene material has no obvious fluorescence effect. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com