Hybrid power battery pack, electrical control system thereof, crane and system working method

An electrical control system and hybrid power technology, applied in battery circuit devices, electric vehicles, electrical components, etc., to achieve the effects of reducing power, reducing noise pollution and exhaust emissions, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

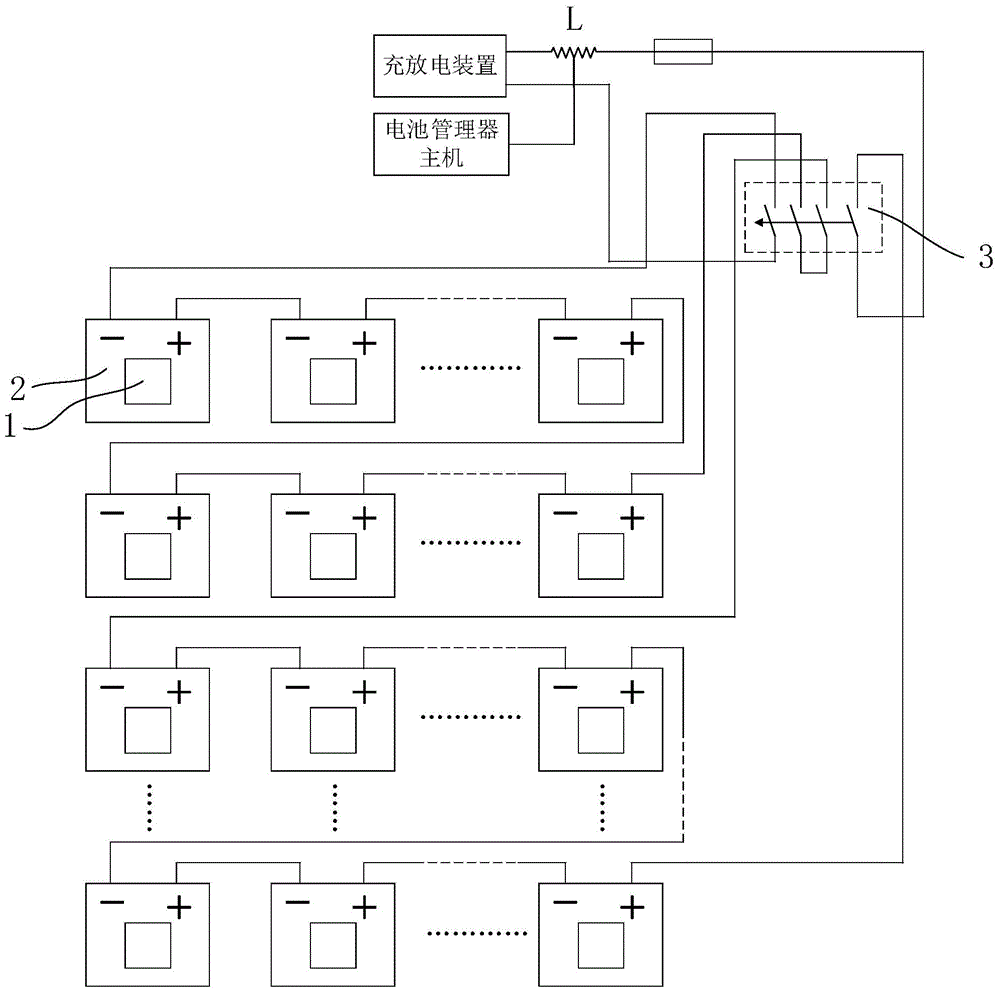

[0029] figure 1 Shown is the wiring diagram for the hybrid battery pack.

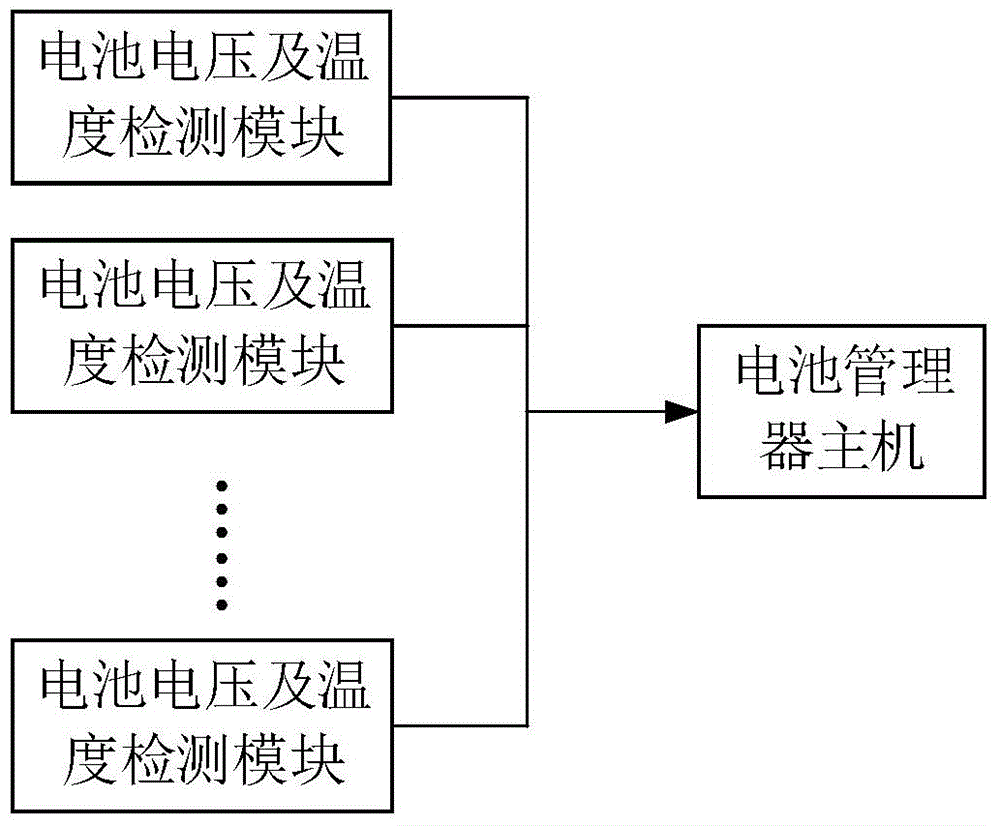

[0030] figure 2 A connection block diagram of the battery manager host and the battery voltage and temperature detection module is shown.

[0031] Such as figure 1 As shown, a hybrid battery pack includes: several batteries 1, and each battery 1 is connected in series respectively, and each battery 1 is respectively provided with a battery voltage and temperature detection module 2, and the output terminals of each battery voltage and temperature detection module 2 It is connected to the signal acquisition terminal of the battery manager host, and the battery manager host is suitable for controlling the charging and discharging parameters of each battery 1 according to the voltage and / or temperature of the battery. Specifically, the voltage of the storage battery is controlled at 660-740V DC charging voltage, the working environment temperature of the battery is controlled within the range of -10°C ...

Embodiment 2

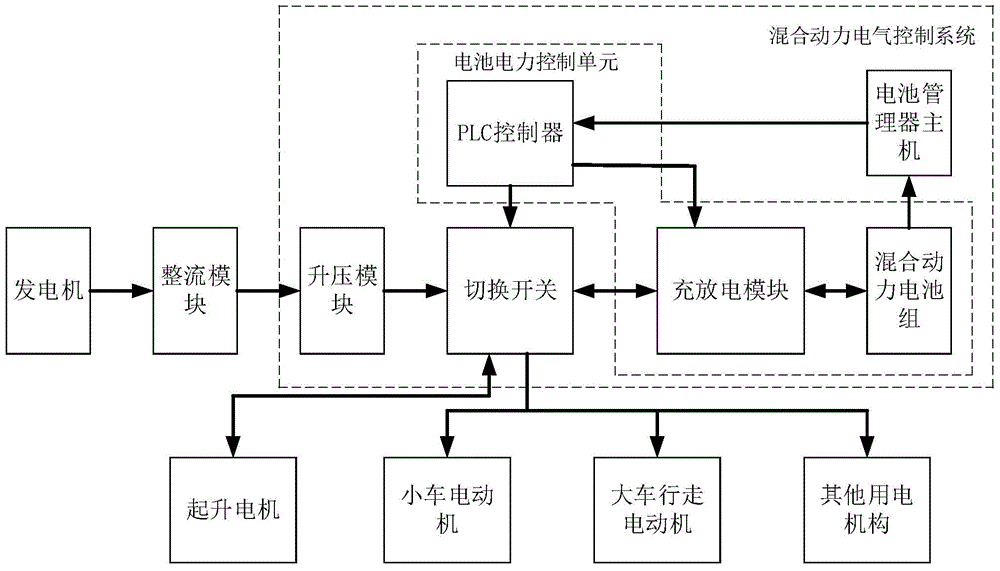

[0035] image 3 A block diagram of the electrical control system is shown.

[0036] Electric control system based on embodiment 1.

[0037] Such as image 3 As shown, an electrical control system for a hybrid battery pack includes: a battery power control unit with a hybrid battery pack inside, and the battery power control unit is adapted to switch the lifting mechanism in the lifting mechanism to The electric energy obtained by the rotation of the lifting motor is stored in the hybrid battery pack, and when the heavy object is lifted, the electric energy is released.

[0038] The battery power control unit includes: a PLC controller and a charging and discharging module connected to the hybrid battery pack; when the weight is lowered, the PLC controller controls the charging and discharging module to store the electric energy obtained by the rotation of the lifting motor in the In the hybrid battery pack; when the weight is lifted, the PLC controller controls the charging...

Embodiment 3

[0047] Such as Figure 1 to Figure 4 As shown, a crane on the basis of Embodiment 1 and Embodiment 2, the crane includes: a hoisting mechanism and an electrical control system, and the electrical control system includes: a battery electric power system with a hybrid battery pack inside A control unit, the battery power control unit is adapted to store the electric energy obtained from the rotation of the lifting motor in the lifting mechanism in the hybrid battery pack when the weight is lowered, and to Electric energy released.

[0048] The cranes include but are not limited to movable cranes, such as tire cranes, crawler cranes, mobile cranes, etc., and fixed cranes, such as wharf cranes, tower cranes, and gantry cranes.

[0049] Optionally, when the weight is lowered, the control and auxiliary power of the whole machine of the crane are provided by the generator.

[0050] The crane also includes a braking unit, which includes a braking resistor, and produces a braking eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com