Graphene-porous ceramic composite adsorbing material and preparation method and application thereof

A technology of composite adsorption materials and porous ceramics, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve problems such as high cost, no mention, and difficulty in large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of graphene-porous ceramic composite adsorption material of the present invention, realizes by following steps:

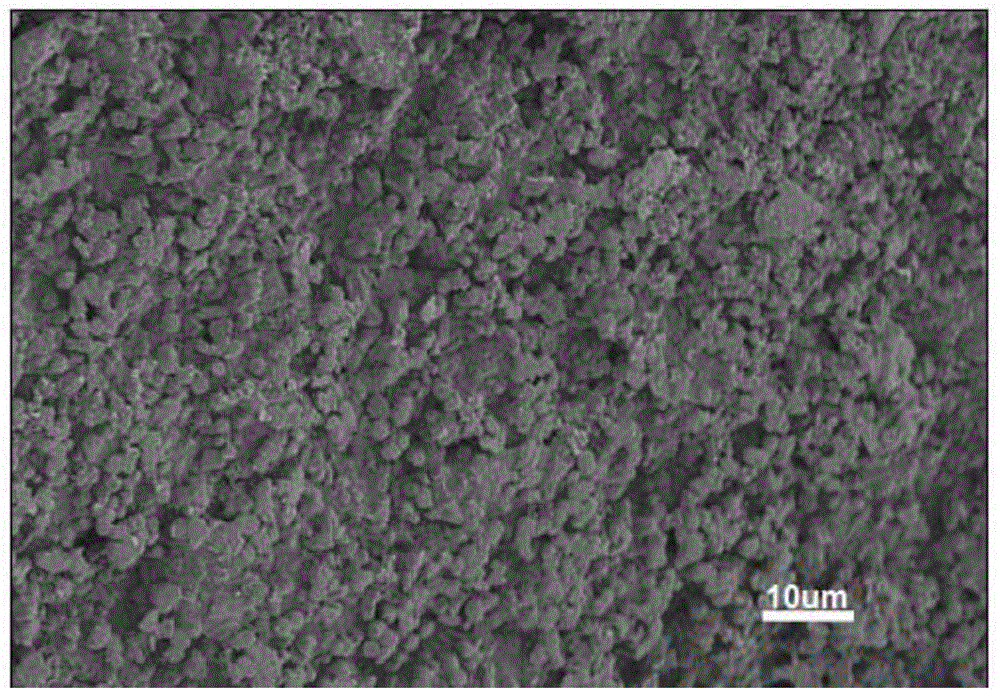

[0032] (1) Clean and dry the blank porous ceramic substrate; the porous ceramic substrate adopts common porous alumina, porous zirconia or porous silica, and the diameter of the pores on it is 2nm-600um, and the blank porous ceramic substrate Microscopic morphology of scanning electron microscope figure 1 shown;

[0033] (2) citric acid and water configuration mass ratio are 250ml of citric acid aqueous solution of 20%; Weigh 60g of the porous ceramic substrate obtained in the above step (1), place the porous ceramic substrate in a muffle furnace, press 5 ℃-20 Heat up to 500°C at a rate of °C / min, and fire at 500°C for 6 minutes. After firing, quickly take out the porous ceramic substrate and immerse it in the above-mentioned prepared citric acid aqueous solution, so that the citric acid is loaded on the inside of the porous ceramic s...

Embodiment 2

[0038](1) Clean and dry the blank porous ceramic substrate; the porous ceramic substrate adopts common porous alumina, porous zirconia or porous silica, and the aperture of the holes on it is 2nm-600um;

[0039] (2) 250ml of 10% sucrose aqueous solution with sucrose and water configuration mass ratio; Weigh 60g of the porous ceramic substrate obtained in the above step (1), place the porous ceramic substrate in a muffle furnace, press 5°C-20°C / Raise the temperature to 500°C at a rate of 1 min, and fire at 500°C for 6 minutes. After firing, quickly take out the porous ceramic substrate and immerse it in the above-mentioned prepared sucrose aqueous solution, so that the sucrose is loaded inside the porous ceramic substrate. After immersion for 24 hours, take out The porous ceramic matrix loaded with sucrose was blown with a hair dryer for 10 minutes, or dried in a fume hood for 24 hours;

[0040] (3) Put the porous ceramic matrix loaded with sucrose into the atmosphere furnace,...

Embodiment 3

[0044] (1) Clean and dry the blank porous ceramic substrate; the porous ceramic substrate adopts common porous alumina, porous zirconia or porous silica, and the aperture of the holes on it is 2nm-600um;

[0045] (2) be made into the mixed aqueous solution 250ml that mass ratio is 15% with the honey of equal quality, glucose with water, take by weighing the porous ceramic substrate of 60g above-mentioned step (1) gained, the porous ceramic substrate is placed in the muffle furnace, press Heat up to 500°C at a rate of 5°C-20°C / min, and fire at 500°C for 6 minutes. After firing, quickly take out the ceramics and immerse them in the above mixed aqueous solution, so that honey and glucose are loaded inside the porous ceramic matrix, and immerse for 24 hours. Finally, take out the porous ceramic matrix loaded with honey and glucose, blow it with a hair dryer for 10 minutes, or dry it in a fume hood for 24 hours;

[0046] (3) Put the porous ceramic matrix loaded with honey and gluco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com