Manufacturing method of iron-based amorphous soft magnetic alloy spherical powder

A soft magnetic alloy and spherical powder technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., to achieve the effect of simple process, good surface quality and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

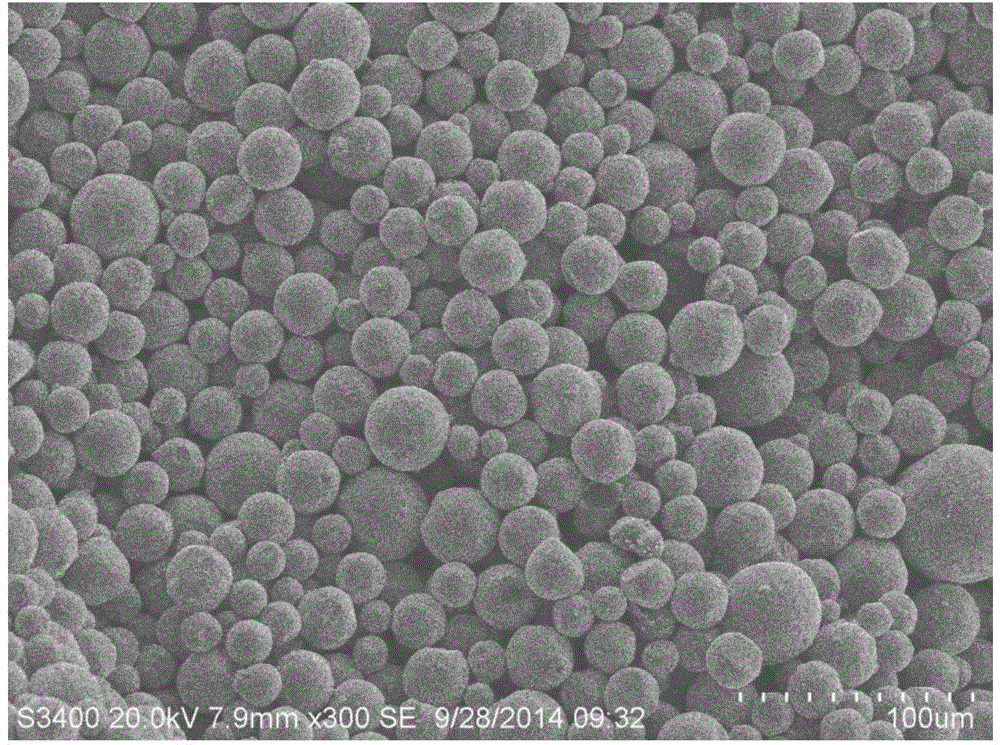

[0025] Preparation of Amorphous Soft Magnetic Alloy Metallic Glass Microspheres. First, smelting to obtain a soft magnetic alloy (Fe 79 Si 6 B 13.3 C 1.7 , subscript atomic percent) Then, mechanically crush the soft magnetic alloy to obtain a powder with an average size of about 30 μm as a raw material. Take 1 gram of soft magnetic alloy powder and flake graphite powder with a size of about 1 μm, and mix them uniformly by mechanical stirring at a ratio of 1:1 by weight.

[0026] Put the mixed soft magnetic alloy / graphite mixed powder into a quartz tube, and the quartz tube is evacuated to 6×10 -3 Pa, pass argon gas to 0.06MPa and then seal the tube, put the quartz tube with alloy / graphite mixed powder protected by argon into a heat treatment furnace heated to 1250°C, keep it warm for 5 minutes, and put the quartz tube protected by argon The quartz tube of alloy / graphite mixed powder is quenched into water to achieve rapid cooling.

[0027] Alloy / graphite powder is soaked...

Embodiment 2

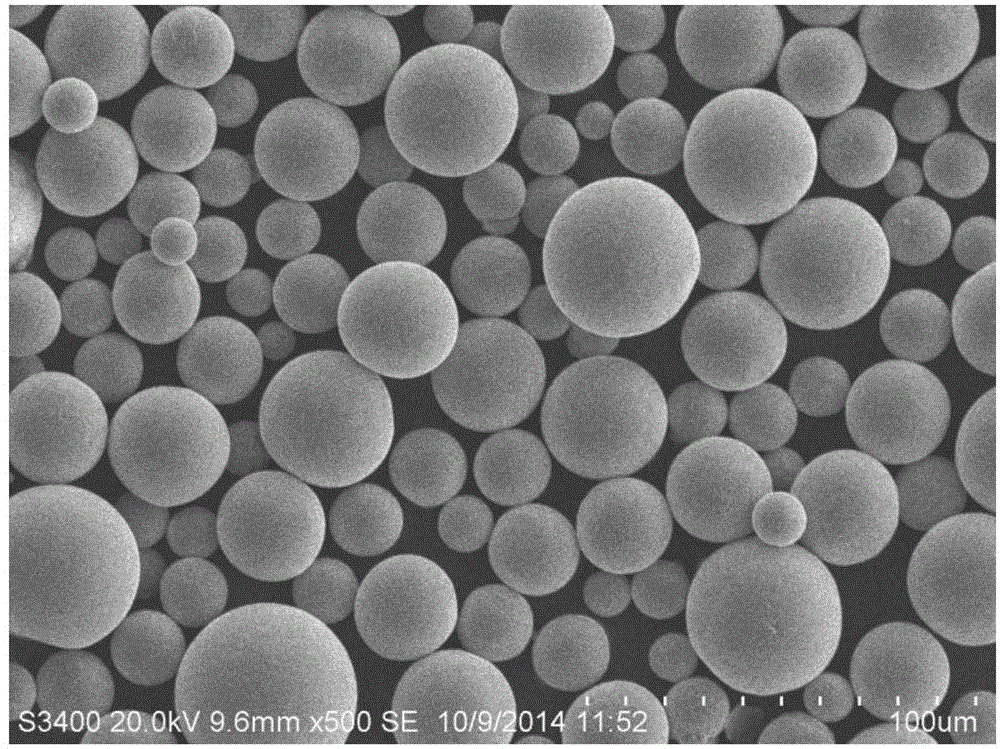

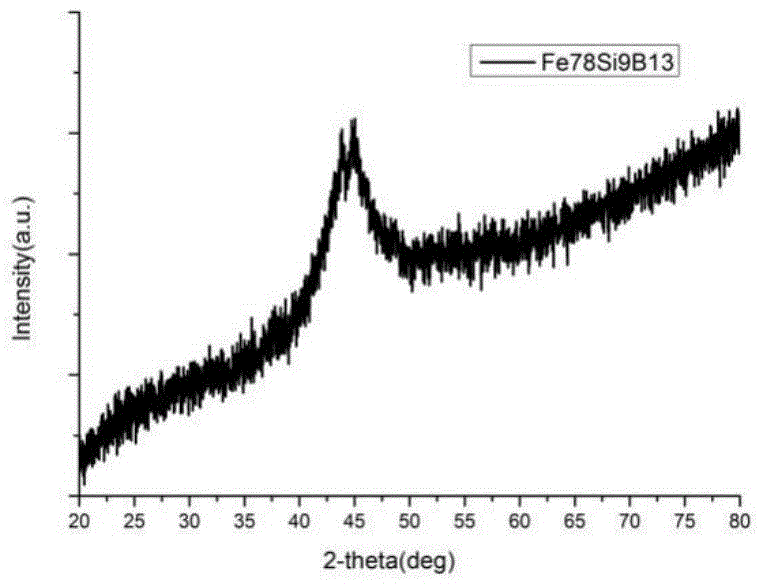

[0029] Preparation of Amorphous Soft Magnetic Alloy Metallic Glass Microspheres. First, soft magnetic alloy powder (Fe 78 Si 9 B 13 , subscript atomic percent) as raw material. Take 1 gram of soft magnetic alloy powder and nano-graphite in a ratio of 5:1 by weight, and mix them uniformly by mechanical stirring.

[0030] Put the mixed soft magnetic alloy / graphite mixed powder into a quartz tube, and the quartz tube is evacuated to 6×10 -3 Pa, blow argon to 0.05MPa and then seal the tube, put the quartz tube filled with FeSiB alloy / graphite mixed powder protected by argon into a heat treatment furnace heated to 1220°C, keep it warm for 3 minutes, and put the quartz tube filled with argon Gas-shielded FeSiB alloy / graphite mixed powder quartz tube is quenched into water or other liquids (such as quenching liquid formula for metal treatment) to achieve rapid cooling.

[0031] Soak the iron-silicon-boron alloy / graphite powder in alcohol, and obtain the iron-silicon-boron metal ...

Embodiment 3

[0033] Preparation of Amorphous Soft Magnetic Alloy Metallic Glass Microspheres. First, smelting to obtain a soft magnetic alloy (Fe 77 Cu 1 Si 9 B 13 , subscript atomic percent). Then, the soft magnetic alloy powder is mechanically crushed as a raw material. Take 1 gram of soft magnetic alloy powder and graphene, and mix them uniformly by mechanical stirring at a ratio of 1:1 by weight.

[0034] Put the mixed soft magnetic alloy / graphite mixed powder into a quartz tube, and the quartz tube is evacuated to 6×10 -3 Pa, pass argon to 0.06MPa and then seal the tube, put the quartz tube with alloy / graphite mixed powder protected by argon into a heat treatment furnace heated to 1200°C, keep it warm for 5 minutes, and put the quartz tube protected by argon The quartz tube of alloy / graphite mixed powder is quenched into water to achieve rapid cooling.

[0035] The alloy / graphite powder is soaked in alcohol, and the metallic glass microspheres are obtained by ultrasonic cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com