Method and system for recycling regenerated waste liquid of sodium bed

A technology for regenerating waste liquid and regenerating liquid, applied in chemical instruments and methods, water treatment parameter control, multi-stage water treatment, etc., can solve the problems of low reaction activity, short replacement cycle, affecting the continuity of sodium bed treatment process, etc. To achieve the effect of simple system structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

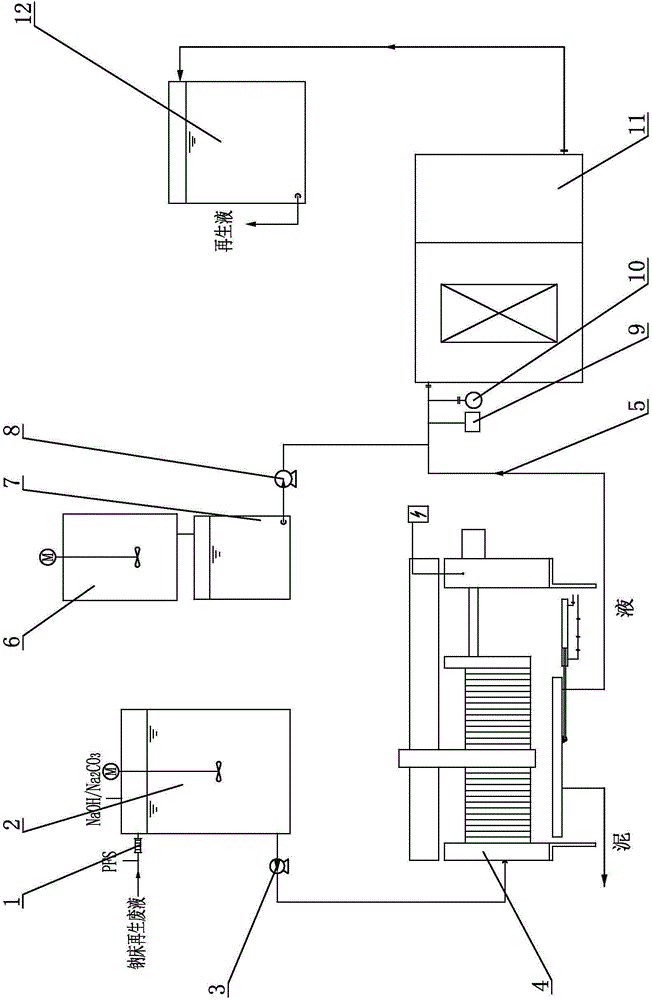

[0025] see figure 1 The sodium bed regeneration waste liquid recycling system of the present embodiment is composed of a pipeline mixer 1, a mixing reactor 2, a screw pump 3, a plate and frame filter press 4, a clear liquid pipeline 5, a salt tank 6, a concentrated salt tank 7, The metering pump 8, the acid adding device 9, the pH meter 10, the submerged ultrafilter 11 and the regeneration liquid recovery tank 12 are connected to form.

[0026] The water inlet port of the pipeline mixer 1 of the present embodiment is processed with a dosing nozzle, through which polyiron is added, and its water inlet is communicated with the sodium bed regeneration waste liquid pipeline, and the water outlet port of the pipeline mixer 1 is connected with the The mixing reactor 2 is connected through pipelines, and the sodium bed regeneration waste liquid added with polyferric is discharged into the mixing reactor 2. The mixing reactor 2 of this embodiment is a mixing reactor 2 with a stirrer. ...

Embodiment 2

[0040] The ultrafiltration membrane used in the submerged ultrafilter 11 in the sodium bed regeneration waste liquid recycling system of this embodiment adopts polyvinylidene fluoride resin material, and the stable permeate output per unit membrane area is 20L / m 2 h, other components are the same as in Example 1.

[0041] In the recycling method of the sodium bed regeneration waste liquid, step (1) detects various indicators of the sodium bed regeneration waste liquid according to conventional methods, and transports the sodium bed regeneration waste liquid to the pipeline mixer 1 through the sodium bed regeneration waste liquid pipeline ; Step (2) in pipeline mixer 1 according to the flow rate and the concentration of sodium bed regeneration waste liquid in the sodium bed regeneration waste liquid, adding concentration is the polyferric chloride solution of 50mg / l, reacts 8 minutes; Step (3) Ca in the sodium bed regeneration waste liquid detected according to step (1) 2+ , M...

Embodiment 3

[0044] The ultrafiltration membrane used in the submerged ultrafilter 11 in the sodium bed regeneration waste liquid recycling system of this embodiment adopts polyvinylidene fluoride resin material, and the stable permeate output per unit membrane area is 15L / m 2 h, other components are the same as in Example 1.

[0045] In the recycling method of the sodium bed regeneration waste liquid, step (1) detects various indicators of the sodium bed regeneration waste liquid according to conventional methods, and transports the sodium bed regeneration waste liquid to the pipeline mixer 1 through the sodium bed regeneration waste liquid pipeline ; Step (2) in pipeline mixer 1 according to the flow rate and the concentration of sodium bed regeneration waste liquid in the sodium bed regeneration waste liquid, adding concentration is the polyferric chloride solution of 90mg / l, reacts 5 minutes; Step (3) Ca in the sodium bed regeneration waste liquid detected according to step (1) 2+ , M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com