Preparation method of seawater corrosion-preventive cement for marine multiplication and cultivation and marine ecological engineering

A technology for ecological engineering and aquaculture enhancement, applied in botany equipment and methods, applications, fish farming, etc., can solve the damage, affect the efficiency of aquaculture enhancement and aquaculture, the ecological restoration effect of marine ecological engineering, and cannot resist long-term immersion and erosion in seawater And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 30kg of fly ash, 24kg of calcium sulfate, and 15kg of silica fume to 80kg of Portland cement, add 90kg of water, stir evenly, use it as cement, and then use the cement to make cement modules, each with a capacity of 2m 3 , respectively fitted with 0.5m 3 Glutinous rice slurry water (mix 50 catties of glutinous rice flour and 450L of fresh water evenly) and 0.5m 3 In small pools of oxalic acid (concentration 5%), each soaked for 24 hours and dried for use, combined with building materials such as bricks to make a cement pool for cultivating Penaeus vannamei.

Embodiment 2

[0022] Add 3kg of fly ash, 2.4kg of calcium sulfate, and 1.5kg of silica fume to 8kg of Portland cement, add 9kg of water, stir evenly, use it as cement material, and then use the cement to make cement modules, each with a capacity of 2m 3 , respectively fitted with 0.5m 3 Glutinous rice slurry water (mix 50 catties of glutinous rice flour and 450L of fresh water evenly) and 0.5m 3 In small pools of oxalic acid (concentration 5%), each soaked for 24 hours and then dried to make a seaweed attachment frame, which is used for seaweed attachment in seaweed ecosystem restoration.

Embodiment 3

[0024] Add 30kg of fly ash, 24kg of calcium sulfate, and 15kg of silica fume to 80kg of Portland cement, add 90kg of water, stir evenly, use it as cement, and then use the cement to make cement modules, each with a capacity of 2m 3 , respectively fitted with 0.5m 3 Glutinous rice slurry water (mix 50 catties of glutinous rice flour and 450L of fresh water evenly) and 0.5m 3 In the small pools of oxalic acid (concentration 5%), dry after each soaking for 24 hours, and install on the surface of mangrove ecosystem coastal buildings.

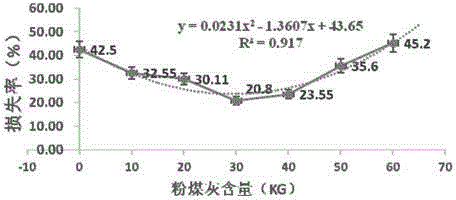

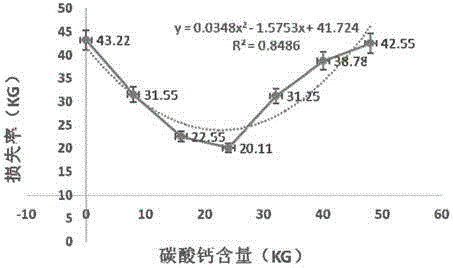

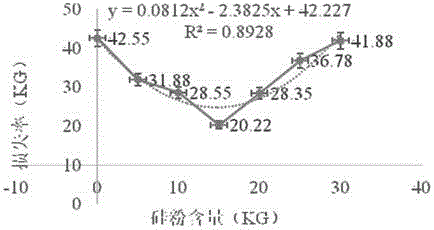

[0025] (1) Optimum formula ratio

[0026] In order to verify the optimal ratio of the formula of the present invention, several experimental groups of cement compositions with different ratios of ingredients were set up for seawater-proof building surfaces, and the anti-seawater erosion ability of different experimental groups was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com