Preparation method for waterproof polyvinyl alcohol / soybean protein isolate PVA / SPI composite membrane

A technology of soybean protein isolate and polyvinyl alcohol, applied in the field of polymer materials, can solve problems such as toxicity or difficult reaction control, and achieve the effects of improving biocompatibility, degradability, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Preparation of SPI aqueous solution: Add 1 g of SPI powder into deionized water, and mechanically stir for 5 min at room temperature to disperse the powder evenly in the water. The mixture was heated and stirred at 80° C. for 30 min to obtain a 7.14 wt % SPI aqueous solution.

[0018] (2) Preparation of PVA aqueous solution: 5 g of PVA was dissolved in 92° C. water for 30 minutes to obtain 10 wt % PVA aqueous solution.

[0019] (3) Preparation of PVA / SPI mixed solution: Mix SPI aqueous solution and PVA aqueous solution at a ratio of 1:5 (w / w), and stir with a magnetic stirrer to make it evenly mixed. The solution was then cooled to room temperature and the initial pH of the solution was tested. Then add a certain amount of 2mol / L NaOH solution to the solution to change the pH of the solution to 11.5. The solution was mixed under mechanical stirring at 80° C. for 60 min.

[0020] (4) Preparation of PVA / SPI film: After the PVA / SPI mixed solution was defoamed at roo...

Embodiment 2

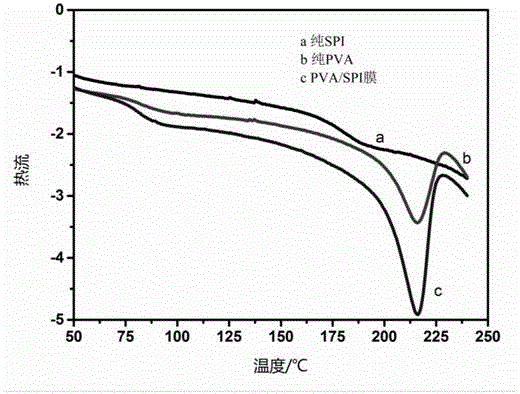

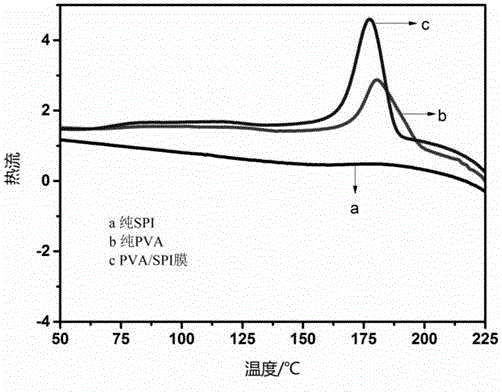

[0022] Differential scanning calorimetry (DSC) is used in DSC 822e under a nitrogen atmosphere with a heating rate of 15°C / min. The pure MFC film, pure PVA film and PVA / SPI composite film are tested respectively. The temperature rises from 25°C Keep at 250°C for 3 minutes, then drop from 250°C to 25°C, then rise from 25°C to 250°C, and end the test. About 8-10mg is used for each sample, and the second temperature rise curve of the composite film is obtained. (1) and cooling curve (2).

[0023] The DSC second heating curve of various membranes (1), we can see from the figure that the pure PVA membrane, the pure SPI membrane does not have a significant glass transition temperature (Tg), and the pure PVA membrane Tg is about 85 ℃, The Tg of PVA / SPI composite film is about 82°C, which is close to that of pure PVA film. In addition, the melting point of the pure PVA film is about 217°C. The melting point of the PVA / SPI composite film is about 215°C, which is slightly lower than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com