Composition for inhibiting alcohol-based fuel for boilers from producing nitrogen oxides

A technology for alcohol-based fuels and nitrogen oxides, which is applied in the field of additives for alcohol-based fuels and additive compositions for inhibiting the formation of nitrogen oxides in alcohol-based fuels. Nitrogen oxides exceed the standard and other problems, to avoid secondary pollution, widely promote the value, and add the effect of appropriate amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Get 11kg of 4-ethoxybenzophenone, 19kg of ethyl 2-hydroxy-3-methylpentanoate, 14kg of 4-ethynyl phenpentyl ether, 2-(4-methoxy-1,4-cyclohexyl Add 26kg of dien-1-yl)-2-propanol, 14.5kg of 3-methyl-1-indanone and 15.5kg of 1-isopropenyl-4-methoxybenzene into the stirring tank, and stir evenly at room temperature to obtain a transparent and clear finished composition for inhibiting the formation of nitrogen oxides in alcohol-based fuels.

[0018] Add 2kg of the composition of this example to 900kg of crude alcohol, mix evenly, and treat it with a BMT-180 ultrasonic instrument of BRANSON, USA for 20 minutes at room temperature, and then add 98kg of conventional additives for other alcohol-based fuels to obtain alcohol-based fuels.

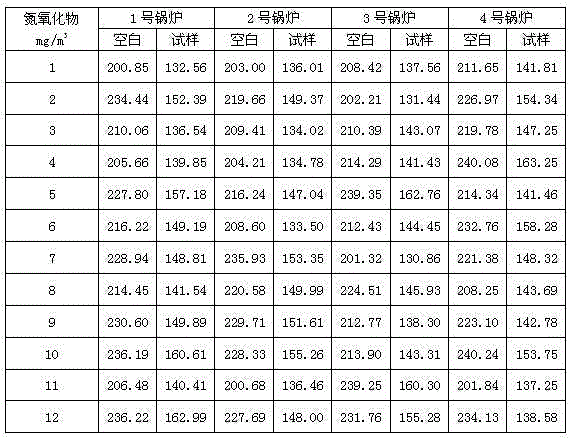

[0019] Nine kinds of crude alcohols and three kinds of methanol were selected from all over the country as basic raw materials to prepare two groups of 24 alcohol-based fuel samples. The first group is a blank control group using 12 kinds of al...

Embodiment 2

[0024] Get 18kg of 4-ethoxybenzophenone, 13kg of ethyl 2-hydroxy-3-methylpentanoate, 20kg of 4-ethynyl phenpentyl ether, 2-(4-methoxy-1,4-cyclohexyl Dien-1-yl)-2-propanol 19.5kg, 3-methyl-1-indanone 13kg and 1-isopropenyl-4-methoxybenzene 16.5kg were added to the stirring tank and stirred evenly at room temperature to obtain a transparent and clear finished composition for inhibiting the formation of nitrogen oxides in alcohol-based fuels.

[0025] Add 4kg of the composition of this example to 800kg of crude alcohol, mix evenly, and treat it with a BMT-180 ultrasonic instrument of BRANSON, USA for 20 minutes at room temperature, and then add 196kg of conventional additives for other alcohol-based fuels to obtain alcohol-based fuels.

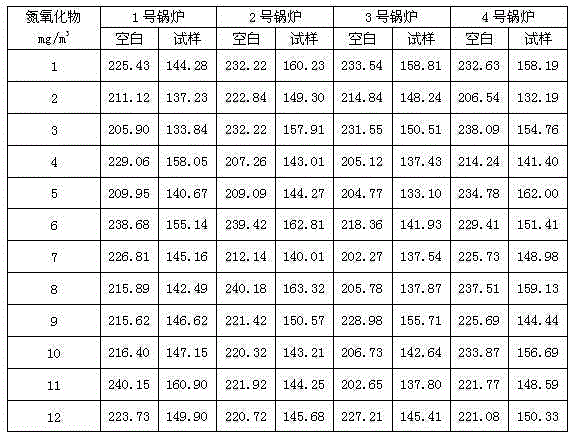

[0026] Carry out test according to embodiment 1 method, detection result is as follows.

[0027]

Embodiment 3

[0029] Get 22kg of 4-ethoxybenzophenone, 14kg of ethyl 2-hydroxy-3-methylpentanoate, 23kg of 4-ethynyl phenpentyl ether, 2-(4-methoxy-1,4-cyclohexyl Dien-1-yl)-2-propanol 17kg, 3-methyl-1-indanone 13kg and 1-isopropenyl-4-methoxybenzene 11kg are added in the stirring tank, and stirred evenly at normal temperature to obtain A transparent and clear finished composition for inhibiting the formation of nitrogen oxides in alcohol-based fuels.

[0030] Add 4kg of the composition of this example to 900kg of methanol, mix evenly, and use BMT-180 ultrasonic instrument of BRANSON of the United States to treat for 20 minutes at room temperature, then add 96kg of other conventional additives for alcohol-based fuels to obtain alcohol-based fuels.

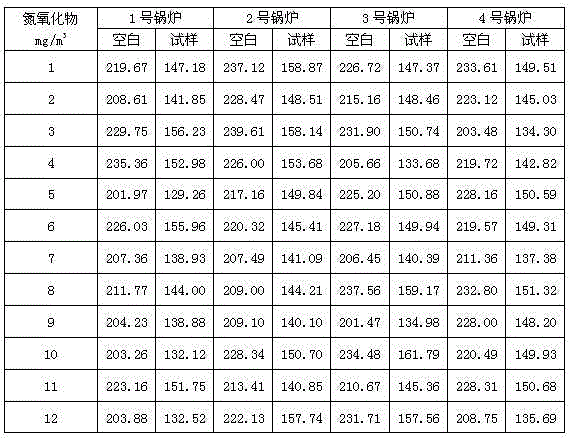

[0031] Carry out test according to embodiment 1 method, detection result is as follows.

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com