A safe and environmentally friendly water-emulsion type rotating drum degreaser, preparation method and application

A safe, environmentally friendly, water-emulsion-type technology, applied in applications, leather degreasing, chemical instruments and methods, etc., can solve problems such as difficult to handle, poisonous and harmful to human body, ozone layer destruction, etc., to achieve clean and smooth fur, good degreasing effect, and degreasing powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

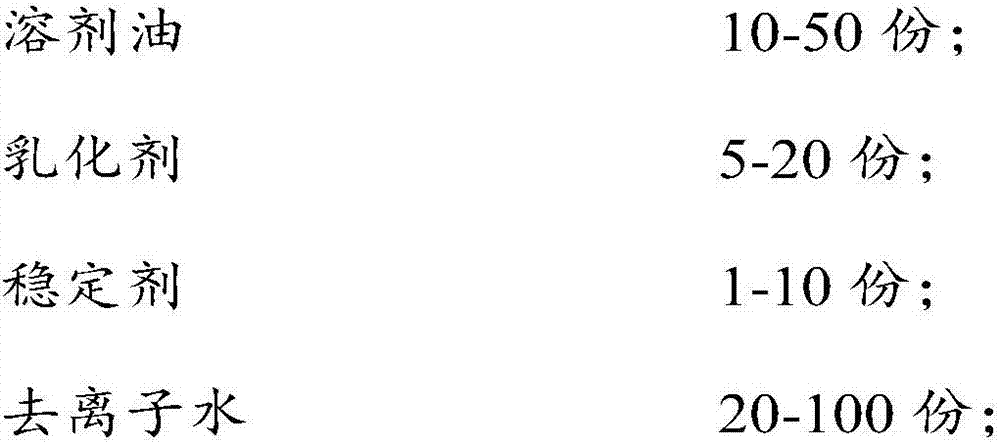

Method used

Image

Examples

Embodiment 1

[0064] The preparation of safe and environment-friendly water-emulsion type drum degreasing agent comprises steps:

[0065] (1) 5 parts of fatty alcohol polyoxyethylene ether (AEO9), 4 parts of fatty alcohol polyoxyethylene ether (AEO7), 5 parts of lauryl amidopropyl betaine, 2 parts of 1.2-propylene glycol, petroleum spirit ( Add 25 parts of D60) into the emulsification kettle in turn, heat at 50-60°C and stir evenly;

[0066] (2) Slowly add 45 parts of deionized water while stirring, and stir at constant temperature for 40 minutes;

[0067] (3) Lower the temperature to below 40° C., stir for another 20 minutes, cool to room temperature, let stand, and discharge to obtain a white milky liquid product.

Embodiment 2

[0069] The preparation of safe and environment-friendly water-emulsion type drum degreasing agent comprises steps:

[0070] (1) 10 parts of fatty alcohol polyoxyethylene ether (AEO9), 5 parts of fatty alcohol polyoxyethylene ether (AEO7), 6 parts of lauryl amidopropyl betaine, 4 parts of 1.2-propylene glycol, petroleum spirit ( Add 40 parts of D60) into the emulsification kettle in turn, heat at 50-60°C and stir evenly;

[0071] (2) Slowly add 50 parts of deionized water while stirring, and stir at constant temperature for 40 minutes;

[0072] (3) Lower the temperature to below 40° C., stir for another 20 minutes, cool to room temperature, let stand, and discharge to obtain a white milky liquid product.

Embodiment 3

[0074] The preparation of safe and environment-friendly water-emulsion type drum degreasing agent comprises steps:

[0075] (1) Add 10 parts of fatty alcohol polyoxyethylene ether (AEO9), 8 parts of coconut oil fatty acid diethanolamide, 4 parts of 1.2-propylene glycol, and 20 parts of odorless turpentine into the emulsification kettle in turn, heat at 50-60°C and stir evenly;

[0076] (2) Slowly add 80 parts of deionized water while stirring, and stir at constant temperature for 40 minutes;

[0077] (3) Lower the temperature to below 40° C., stir for another 20 minutes, cool to room temperature, let stand, and discharge to obtain a white milky liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com