In-situ preparation method of mesoporous alumina loaded with platinum nanoparticles

A technology of mesoporous alumina and platinum nanoparticles, which is applied in the field of nanomaterials, can solve the problems of easy agglomeration of nano metal particles and insufficient dispersion of nano metal particles, and achieves easy technology mastery, is conducive to technology promotion and application, and low investment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Preparation of Al-Pt binary alloy

[0025] (1) Take 216 mm of platinum wire with a diameter of 0.5 mm and fix it on a pure Al target with a diameter of 50 mm in 5 sections to make an Al-Pt composite target;

[0026] (2) Take another pure Al target with a diameter of 50 mm as the second target;

[0027] (3) Put the two targets into the sample chamber, set the sputtering current of the pure Al target to 320mA, the sputtering current of the Al-Pt composite target to 110mA, and the magnetron sputtering time to 10min. A layer of Al-Pt binary alloy is sputtered on the substrate;

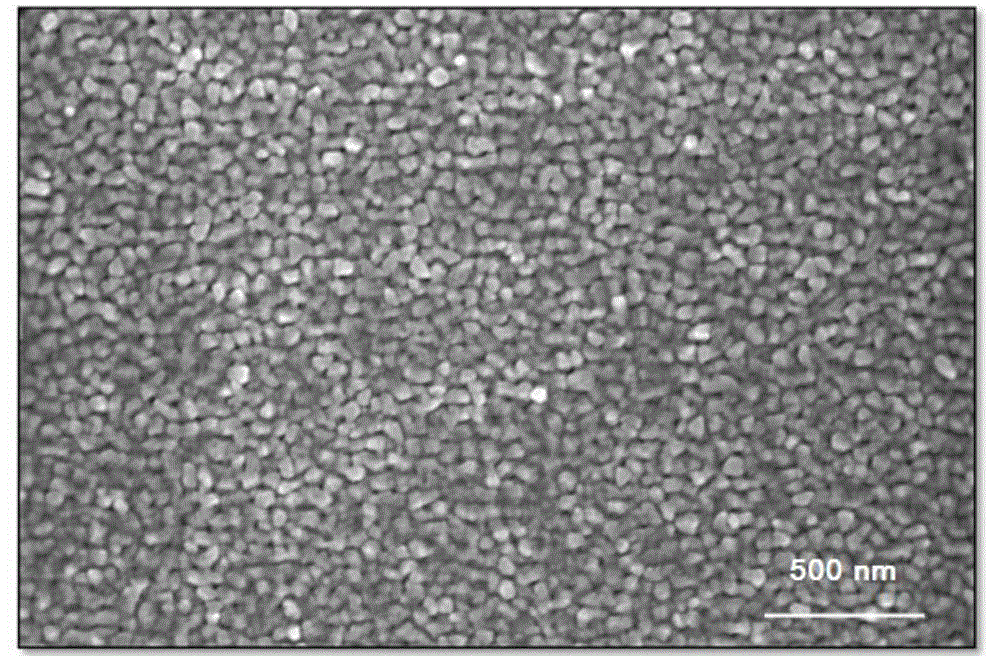

[0028] (4) Observing the surface morphology of the Al-Pt binary alloy with a field emission scanning electron microscope, such as figure 1 shown;

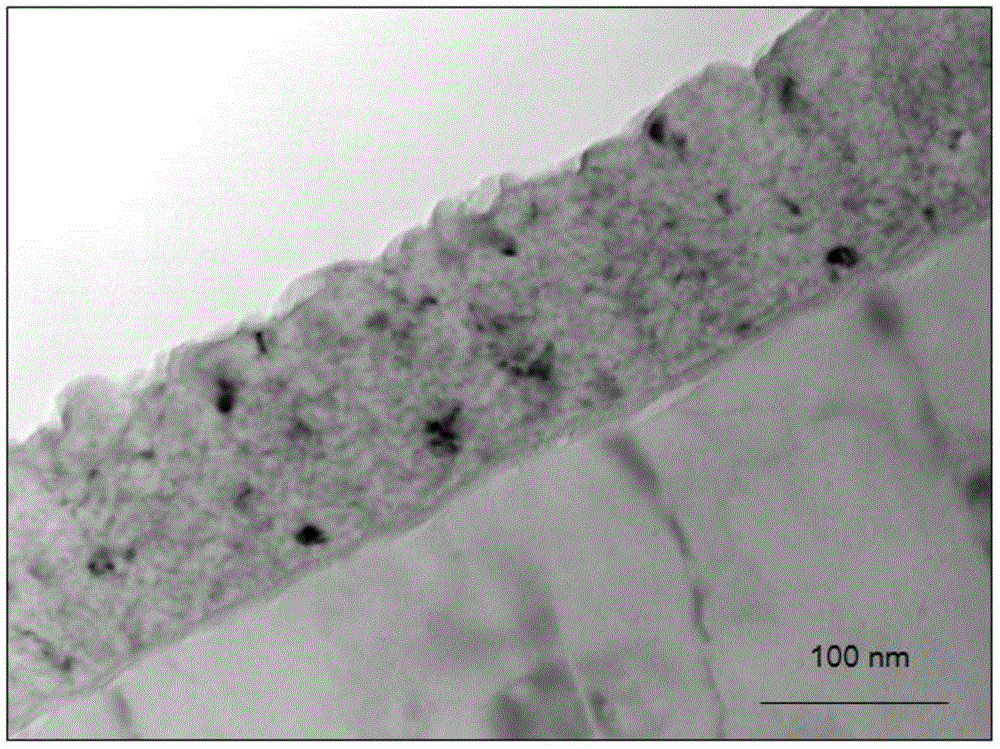

[0029] (5) Adopt microdissection technique to prepare transmission electron microscope sample (sample nominal thickness 15nm), then carry out tissue observation on transmission electron microscope, as figure 2 As shown, the thickness of the Al-Pt...

Embodiment 2

[0037] a. Preparation of Al-Pt binary alloy

[0038] The preparation process of the Al-Pt binary alloy is the same as step a in Example 1.

[0039] b. Preparation of Platinum Nanoparticles Supported Mesoporous Alumina

[0040] (1) is the same as (1) in the b step in embodiment 1.

[0041] (2) is the same as (2) in the b step in embodiment 1.

[0042] (3) Carry out anodic oxidation on the potentiostat: put the sealed sample into the prepared sulfuric acid aqueous solution and connect with the positive pole of the power supply; connect the negative pole of the power supply with the ring-shaped pure aluminum sheet; use saturated calomel electrode as the Reference electrode: anodized at a constant potential of 3V (OCP) for 20min to prepare platinum nanoparticles supported mesoporous alumina.

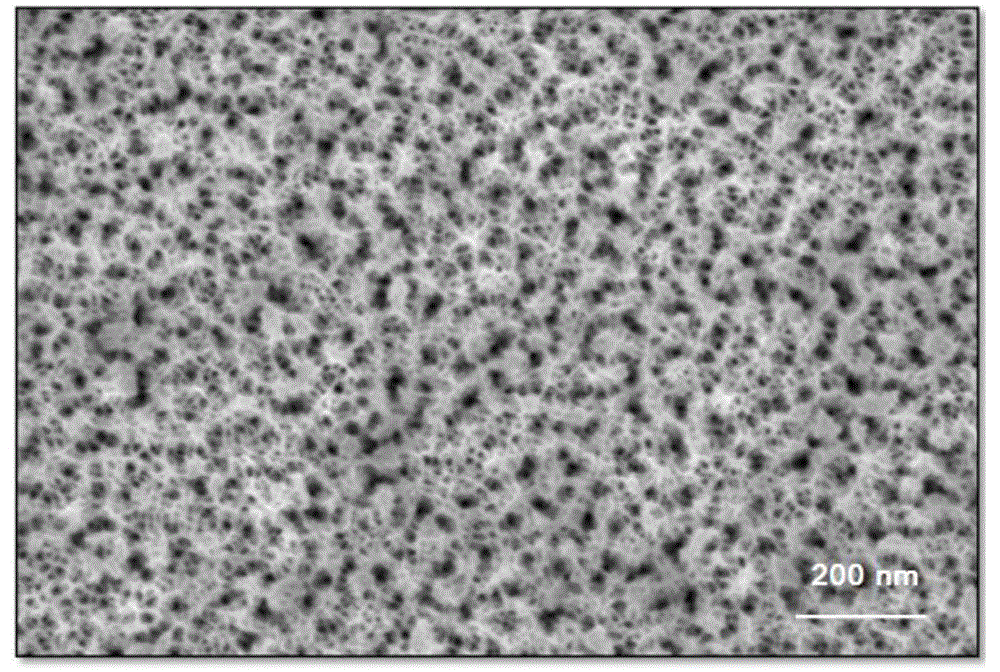

[0043] (4) Field emission scanning electron microscopy was used to observe the surface morphology of platinum nanoparticles loaded mesoporous alumina, as shown in Figure 5As shown, the ...

Embodiment 3

[0046] a. Preparation of Al-Pt binary alloy

[0047] (1) Take 95 mm of platinum wire with a diameter of 1 mm and fix it on a pure Al target with a diameter of 50 mm in two sections to make an Al-Pt composite target;

[0048] (2) Take another pure Al target with a diameter of 50 mm as the second target;

[0049] (3) Put the two targets into the sample chamber, set the sputtering current of the pure Al target to 200mA, the sputtering current of the Al-Pt composite target to 200mA, and the magnetron sputtering time to 15min. A layer of Al-Pt binary alloy is sputtered on the substrate, wherein the thickness of the Al-Pt binary alloy is about 165 nm, and the composition (atomic percentage) is 96.5% Al, 3.5% Pt.

[0050] b. Anodized Al-Pt binary alloy

[0051] (1) get the concentrated sulfuric acid (density is 1.84g / cm3) that concentration is 98.3% 3 ) 0.32ml, slowly added to an appropriate amount of deionized water to prepare a 0.6M sulfuric acid aqueous solution;

[0052] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com