Composite nanofibre diaphragm with thermal pore-closing function, preparation method and energy storage device

A technology of composite nanofibers and nanofibers, applied in the direction of separators/films/diaphragms/spacers, hybrid capacitor separators, structural parts, etc., can solve problems such as explosions and battery combustion, and achieve simple production processes and convenient transfer , suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

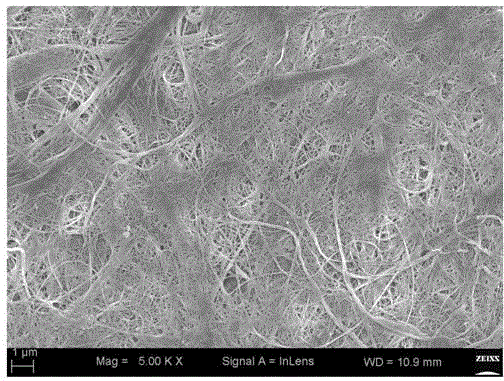

[0048] Fibrillated cellulose nanofibers: low-melting polymer nanofibers = 9:1 cellulose nanofibers and low-melting polymer nanofibers (polymethyl methacrylate and polysuccinic acid) separated from nano-sized wood materials Glycol esters) are dispersed in a solvent, and then the solution is uniformly uniformed by high-speed mechanical agitation to prepare a slurry. Add a solvent to dilute the slurry to 0.01%, dehydrate the diluted slurry on the Internet; press and dry; hot-roll forming at a molding temperature of 100°C and a line pressure of 100kg / cm, and then roll paper, Rewinding, slitting and packaging to produce battery separators.

[0049] The above-mentioned closed-cell composite separator exhibits excellent properties, for example, at 200°C, the porosity before and after 2h heat treatment is 56% and 55%, respectively; at 200°C, the thermal shrinkage rate is almost 0 in 30min; , The Gurley value (s / 100cc) before and after 2h heat treatment was 23 and 23.

Embodiment 2

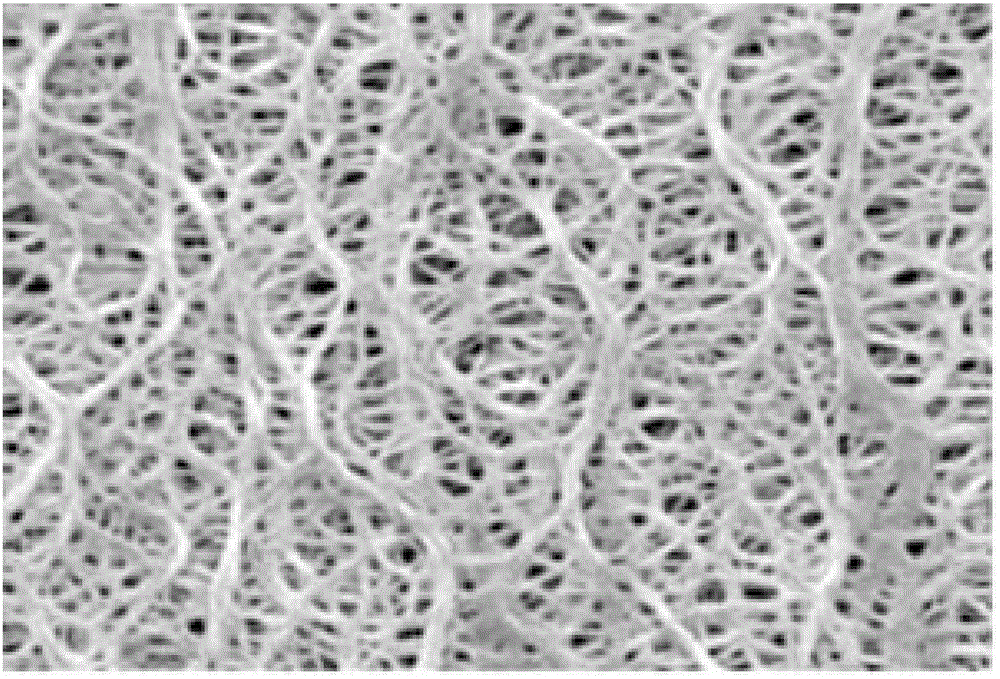

[0051] The fibrillated cellulose nanofibers: low-melting polymer nanofibers = 7:3 seaweed cellulose nanofibers and low-melting polymer nanofibers (vinylidene fluoride-based polymers) were dispersed in a solvent, and then passed through a high-speed machine Stir to make the solution uniform throughout to prepare a slurry. Add a solvent to dilute the slurry to 0.01%, dehydrate the diluted slurry on the Internet; press and dry; hot-roll forming at a molding temperature of 100°C and a line pressure of 100kg / cm, and then roll paper, Rewinding, slitting and packaging to produce battery separators.

[0052] The above-mentioned closed-cell composite separator exhibits excellent properties, for example, the porosity before and after heat treatment at 200°C for 2h is 56% and 30%, respectively; the thermal shrinkage rate is almost 1% at 200°C for 30min; the percentage of liquid absorption is 300% ; 200 ℃, Gurley value (s / 100cc) before and after 2h heat treatment is 23 and 800.

Embodiment 3

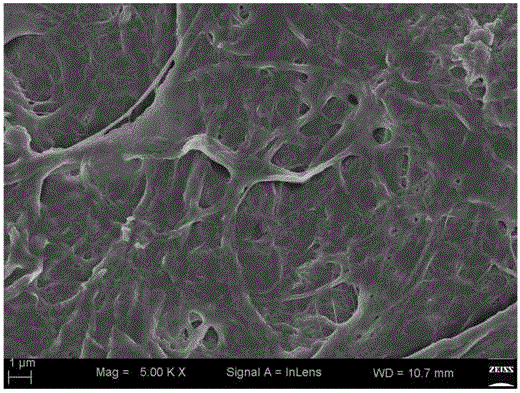

[0054] Bacterial cellulose nanofibers and low-melting-point polymer nanofibers (polyurethane, polyvinyl chloride, and polyolefin) obtained by culturing strains of fibrillated cellulose nanofibers: low-melting-point polymer nanofibers = 5:5 were dispersed in a solvent , and then prepare the slurry by high-speed mechanical agitation to make the solution uniform throughout. Add a solvent to dilute the slurry to 0.01%, dehydrate the diluted slurry on the Internet; press and dry; hot-roll forming at a molding temperature of 100°C and a line pressure of 100kg / cm, and then roll paper, Rewinding, slitting and packaging to produce battery separators.

[0055] The above-mentioned closed-cell composite diaphragm exhibits excellent properties, for example, at 200°C, the porosity before and after 2h heat treatment is 54% and 18%, respectively; at 200°C, 1.4% heat shrinkage rate at 30min; 285% liquid absorption percentage; 200% ℃, Gurley value (s / 100cc) before and after 2h heat treatment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com