Polysiloxane- and polyphosphonic acid-doped chitosan high-temperature proton exchange film and preparation method thereof

A proton exchange membrane, polysiloxane technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, solid electrolyte fuel cells, etc. Time and other issues, to achieve the effect of low cost, avoiding the decline of electrical conductivity, and alleviating the problem of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

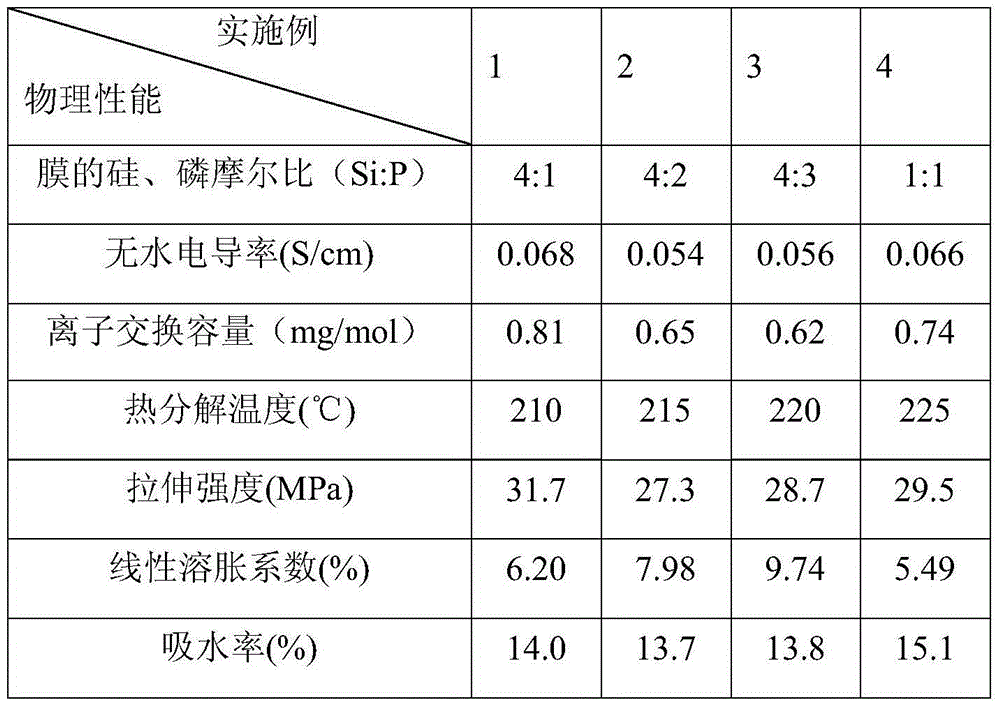

Embodiment 1

[0028] A polysiloxane polyphosphonic acid doped chitosan high-temperature proton exchange membrane, which is prepared according to the following steps:

[0029] At room temperature, dissolve 0.1g chitosan powder in 20mL, 1% (v / v) acetic acid aqueous solution to configure 0.5wt% chitosan acetic acid aqueous solution, and fully stir to dissolve it evenly; weigh 0.9855 g2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane and 0.09968g aminotrimethylene phosphonic acid (silicon, phosphorus molar ratio is 4.0:1.0), and they were dissolved in 10mL deionized water to prepare Siloxane solution and organic polyphosphonic acid solution; add the prepared siloxane solution to the above-mentioned chitosan solution at room temperature, and continue to stir for 2 hours; put the obtained mixed solution into an ice-water mixing bath, slowly drop Add organic polyphosphonic acid solution and continue stirring for 12 hours to obtain a sol; pour the sol into a polytetrafluoroethylene mold, dry it in vacuu...

Embodiment 2

[0031] A polysiloxane polyphosphonic acid doped chitosan high-temperature proton exchange membrane, which is prepared according to the following steps:

[0032] At room temperature, dissolve 0.4g chitosan powder in 20mL, 2% (v / v) acetic acid aqueous solution to configure 2wt% chitosan acetic acid aqueous solution, and fully stir to make it dissolve evenly; weigh 0.9454g gamma- (2,3-Glycidoxypropoxy)propyltrimethoxysilane and 0.2060g hydroxyethylidene diphosphonic acid (silicon, phosphorus molar ratio is 4.0:2.0), and dissolved in 10mL deionized water respectively into a siloxane solution and an organic polyphosphonic acid solution; add the prepared siloxane solution to the above-mentioned chitosan solution at room temperature, and continue to stir for 3 hours; put the obtained mixed solution into an ice-water mixing bath, slowly Add organic polyphosphonic acid solution dropwise, and keep stirring for 15 hours to obtain a sol; pour the sol into a polytetrafluoroethylene mold, d...

Embodiment 3

[0034] A polysiloxane polyphosphonic acid doped chitosan high-temperature proton exchange membrane, which is prepared according to the following steps:

[0035]At room temperature, 0.6g chitosan powder was dissolved in 20mL, 3% (v / v) acetic acid aqueous solution to configure 3wt% chitosan acetic acid aqueous solution, and fully stirred to make it dissolve evenly; weighed 0.9855g2- (3,4-epoxycyclohexyl)ethyltrimethoxysilane and 0.2991g aminotrimethylene phosphonic acid (silicon, phosphorus molar ratio is 4.0:3.0), and they were dissolved in 20mL deionized water to prepare silicon oxide alkane solution and organic polyphosphonic acid solution; add the prepared siloxane solution to the above-mentioned chitosan solution at room temperature, and continue to stir for 4 hours; put the obtained mixed solution into an ice-water mixing bath, and slowly add organic Polyphosphonic acid solution was continuously stirred for 18 hours to obtain a sol; the sol was poured into a polytetrafluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com