Applications of chitosan and chitosan derivative

A chitosan derivative, chitosan technology, applied in the application field of chitosan and its derivatives, to achieve good sedimentation effect, improve public health, and enhance the effect of application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

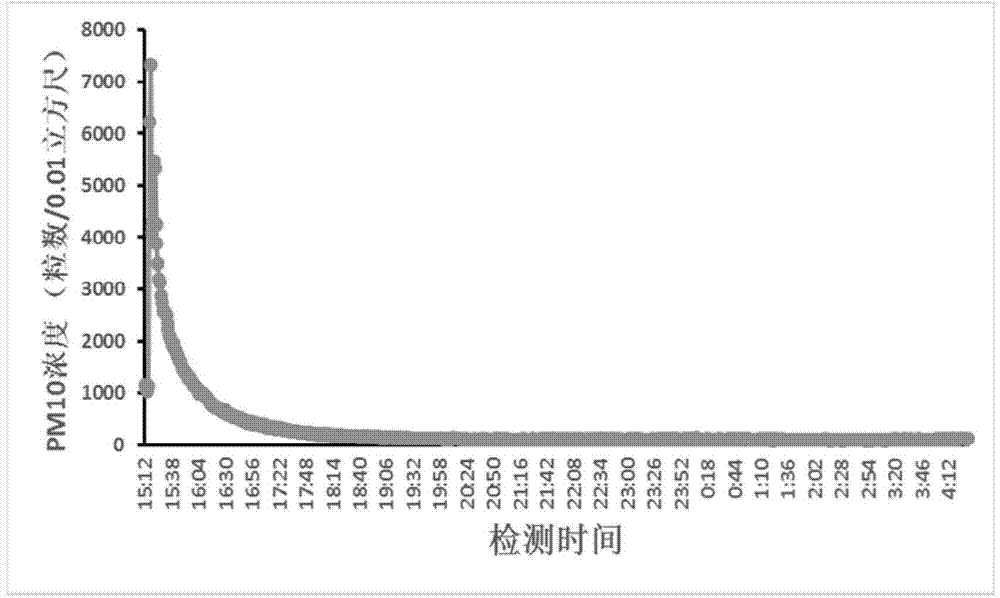

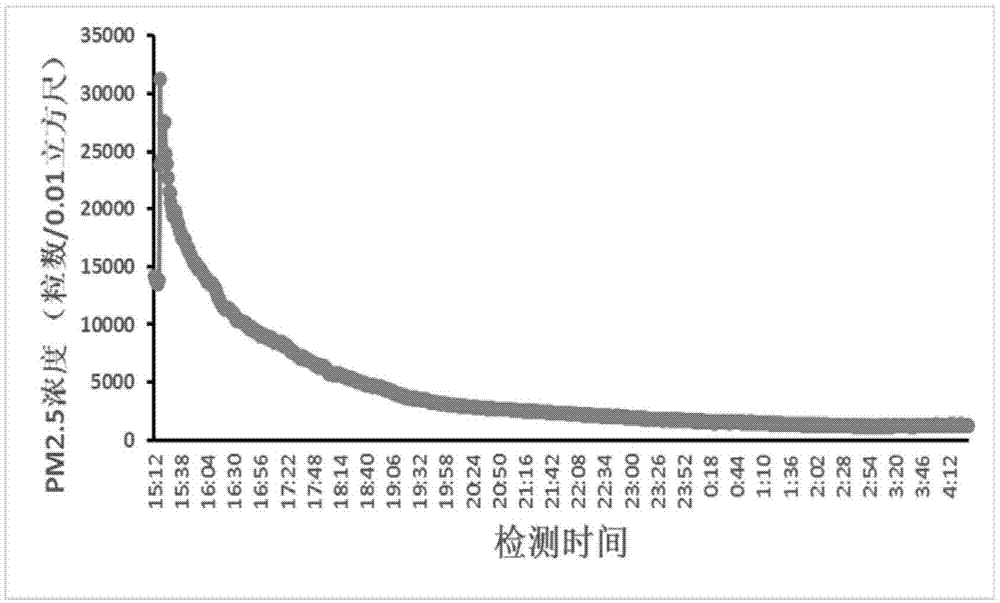

[0023] Dissolve 2 g of chitosan (1800 kDa) in 1000 ml of 0.2% (mass fraction) acetic acid to obtain a chitosan solution, and then put the chitosan solution into an atomizing device. In a closed laboratory (35m 3 ), through the air particle counter (Dylos 1700, produced in the United States) to monitor the concentration of fine particulate matter PM10 and PM2.5 in the indoor air in real time (the concentration is measured by the number of particles / 0.01 cubic feet). After the fine particle readings in the closed laboratory are stable, the prepared chitosan solution is sprayed in the air in the laboratory through an atomization device, and the solution sprays 6.5mL, and the fine particle PM10 in the laboratory (see figure 1 ) and PM2.5 (see figure 2 ) concentration changes. Such as figure 1 and figure 2 It is shown that after spraying the chitosan solution, the concentration of PM10 and PM2.5 in the room both increased briefly and then decreased rapidly. This is mainly be...

Embodiment 2

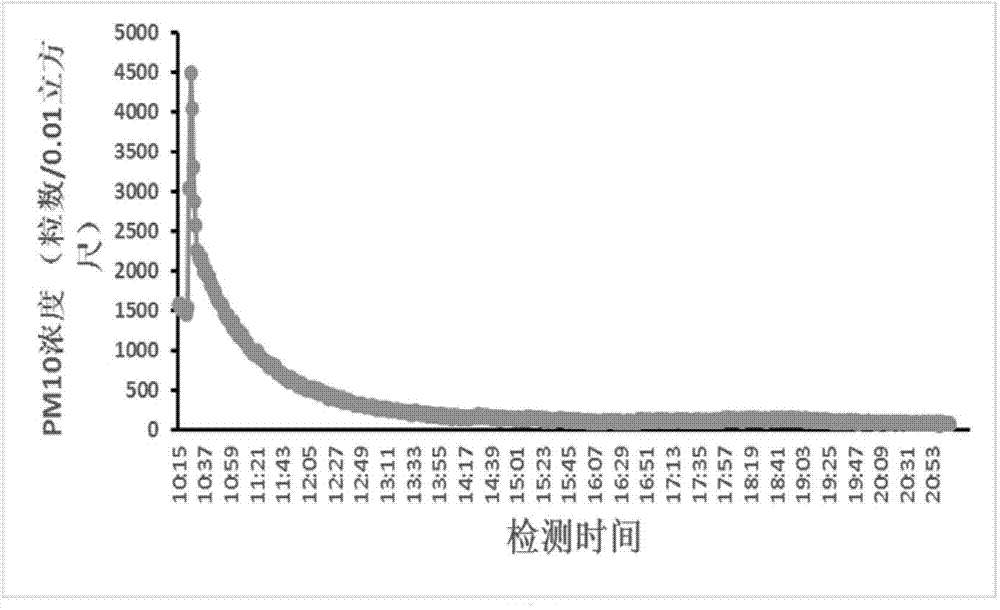

[0025] Dissolve 2 g of carboxymethyl chitosan (the degree of substitution is 80%) in 1000 ml of distilled water to obtain a carboxymethyl chitosan solution, and then put the carboxymethyl chitosan solution into an atomizing device. In a closed laboratory (35m 3 ), through the air particle counter (Dylos 1700, produced in the United States) to monitor the concentration of fine particulate matter PM10 and PM2.5 in the indoor air in real time (the concentration is measured by the number of particles / 0.01 cubic feet). After the fine particle readings in the closed laboratory are stable, the prepared carboxymethyl chitosan solution is sprayed in the air in the laboratory through an atomization device, and the solution sprays 6.5mL, and the fine particle PM10 in the laboratory (see image 3 ) and PM2.5 (see Figure 4 ) concentration changes. Such as image 3 and Figure 4 It is shown that after spraying carboxymethyl chitosan solution, the concentration of PM10 and PM2.5 in the ...

Embodiment 3

[0027] N-trimethyl chitosan quaternary ammonium salt (substitution degree is 100%) 2g is dissolved in 1000ml distilled water to obtain N-trimethyl chitosan quaternary ammonium salt solution, after the N-trimethyl chitosan quaternary ammonium salt solution The ammonium salt solution is loaded into the atomization device. In a closed laboratory (35m 3 ), through the air particle counter (Dylos 1700, produced in the United States) to monitor the concentration of fine particulate matter PM10 and PM2.5 in the indoor air in real time (the concentration is measured by the number of particles / 0.01 cubic feet). After the readings of the fine particles in the closed laboratory are stable, the prepared N-trimethyl chitosan quaternary ammonium salt solution is sprayed in the air in the laboratory through the atomization device, and the solution is sprayed 6.5mL, and the fine particles in the laboratory PM10( see Figure 5 ) and PM2.5 (see Figure 6 ) concentration changes. Such as F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com