Carbon-supported iron-doped tricobalt tetraoxide nanocrystal composite catalyst and preparation method thereof

A nano-composite catalyst technology of cobalt trioxide, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as high-cost manufacturing processes, and achieve simplified preparation methods , superior performance and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

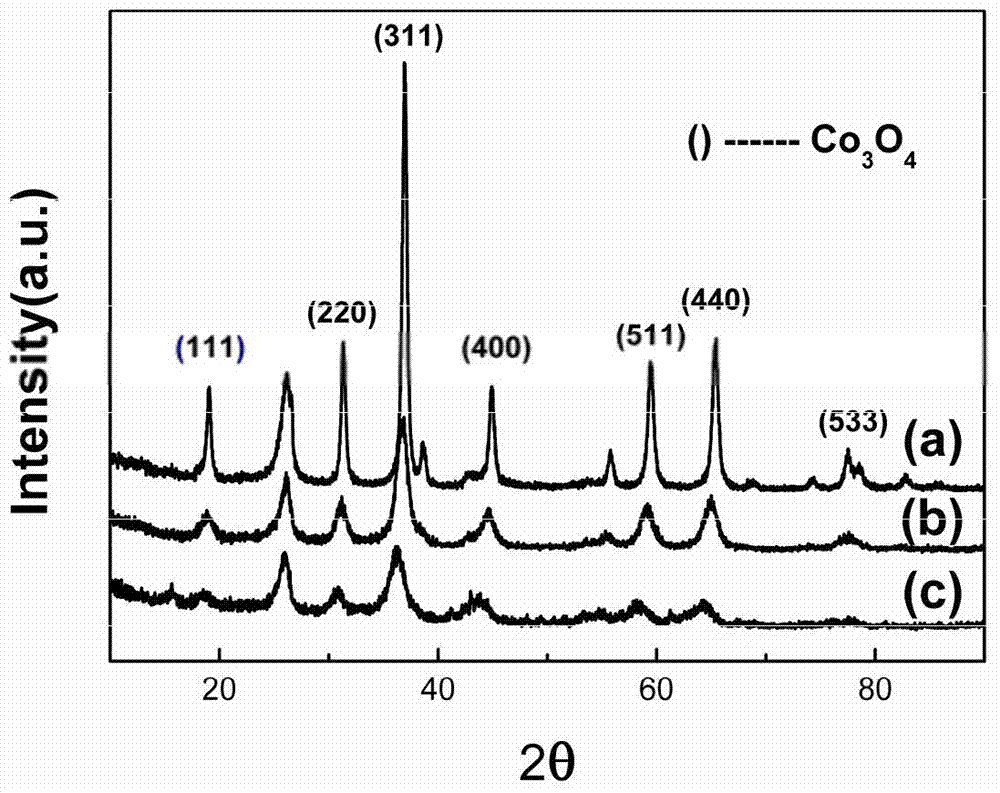

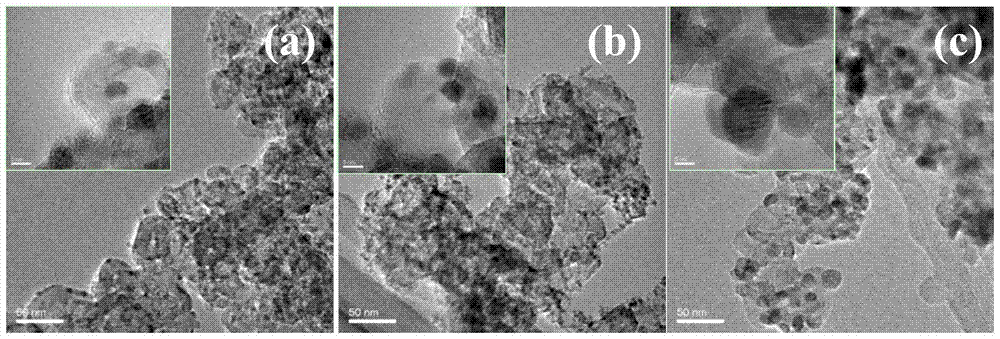

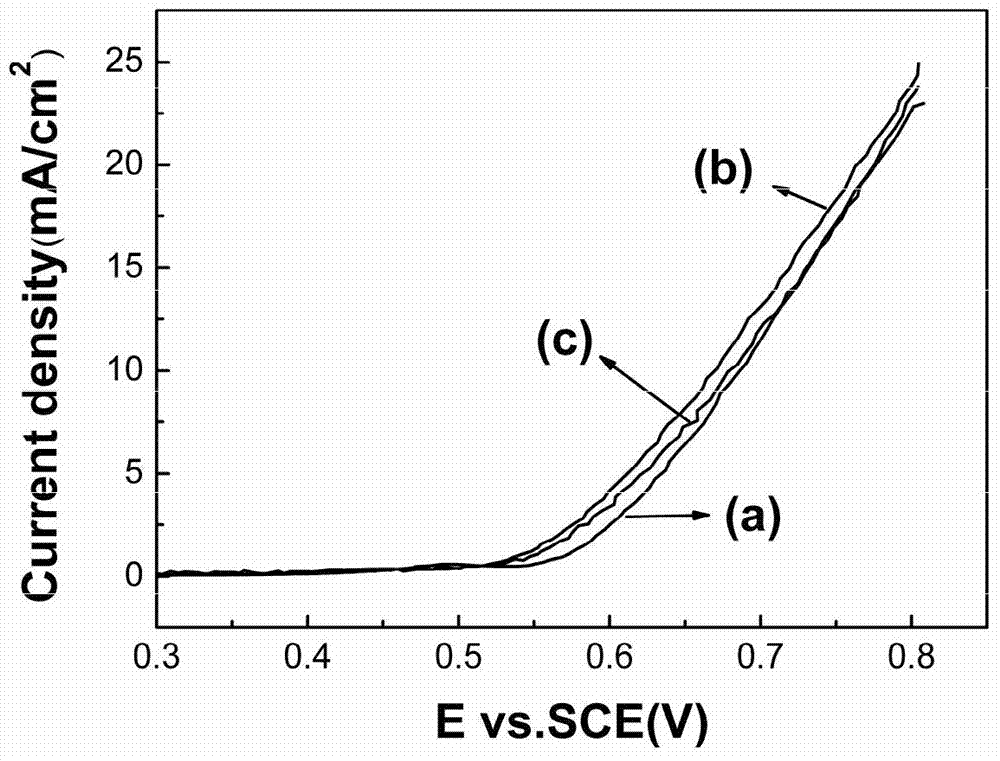

Embodiment 1

[0027] Ferric nitrate was used as iron salt precursor for doping.

[0028] (1) Prepare a certain proportion of 0.05mol / L soluble cobalt salt in an alcoholic aqueous solution, add nitric acid-treated carbon black into the solution, ultrasonically disperse for 15min to 60min, add dropwise ammonia water with a volume fraction of 20%, and ultrasonically disperse for 15min to 60min, Dissolve a certain amount of iron salt precursor in the solution, the molar ratio of cobalt to iron is 1:1, and press to obtain a suspension containing cobalt salt, iron salt and carbon black carrier.

[0029] (2) Pour the solution into the flask, condense and reflux in a magnetically stirred oil bath, the oil bath temperature is constant, and the reaction time is 10h. After the reaction, the reaction solution is suction filtered, washed, and dried under 80°C. ℃ drying for 12h. The composite catalyst precursor solid powder is obtained.

[0030] (3) Heat-treat the obtained solid powder of the composite...

Embodiment 2

[0033] Doping with ferrous sulfate as iron salt precursor.

[0034] (1) Prepare a certain proportion of 0.05mol / L soluble cobalt salt in an alcoholic aqueous solution, add nitric acid-treated carbon black into the solution, ultrasonically disperse for 15min to 60min, add dropwise ammonia water with a volume fraction of 20%, and ultrasonically disperse for 15min to 60min, A certain amount of iron salt precursor is dissolved in the solution, the molar ratio of cobalt to iron is 1:1, and a suspension containing cobalt salt, iron salt and carbon black carrier is obtained.

[0035] (2) Pour the solution into the flask, condense and reflux in a magnetically stirred oil bath, the oil bath temperature is constant, and the reaction time is 10h. After the reaction, the reaction solution is suction filtered, washed, and dried under 80°C. ℃ drying for 12h. The composite catalyst precursor solid powder is obtained.

[0036] (3) Heat-treat the obtained solid powder of the composite cataly...

Embodiment 3

[0039] Adjust the molar ratio of cobalt to iron to be 3:1.

[0040] (1) Prepare a certain proportion of 0.05mol / L soluble cobalt salt in an alcoholic aqueous solution, add nitric acid-treated carbon black into the solution, ultrasonically disperse for 15min to 60min, add dropwise ammonia water with a volume fraction of 20%, and ultrasonically disperse for 15min to 60min, A certain amount of ferric nitrate is dissolved in the solution, the molar ratio of cobalt to iron is 3:1, and a suspension containing cobalt salt, iron salt and carbon black carrier is obtained.

[0041] (2) Pour the solution into the flask, condense and reflux in a magnetically stirred oil bath, the oil bath temperature is constant, and the reaction time is 10h. After the reaction, the reaction solution is suction filtered, washed, and dried under 80°C. ℃ drying for 12h. The composite catalyst precursor solid powder is obtained.

[0042] (3) Heat-treat the obtained solid powder of the composite catalyst pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com