Preparation method of cadmium selenide nanocrystal assembly with narrow size distribution

A nanocrystalline, narrow-sized technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of difficult assembly of nanocrystals, achieve low cost, easy operation, and improve photovoltaic conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

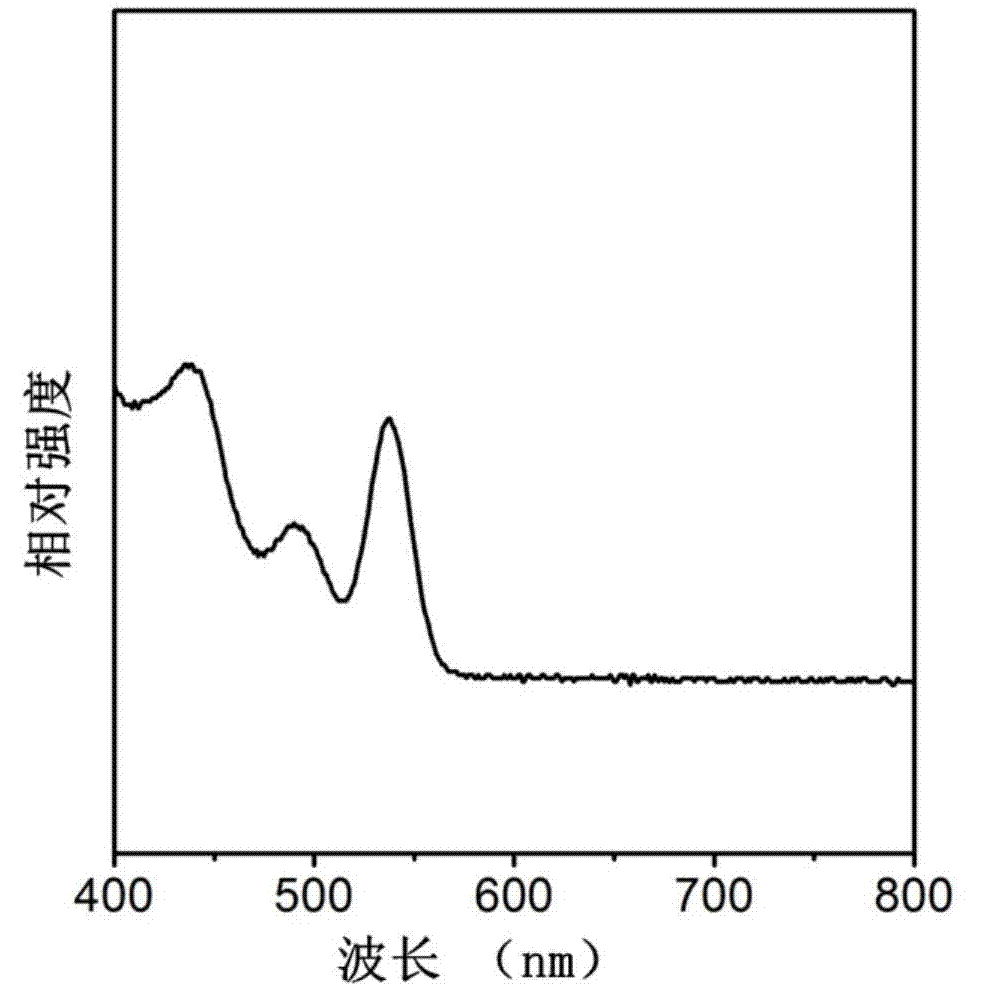

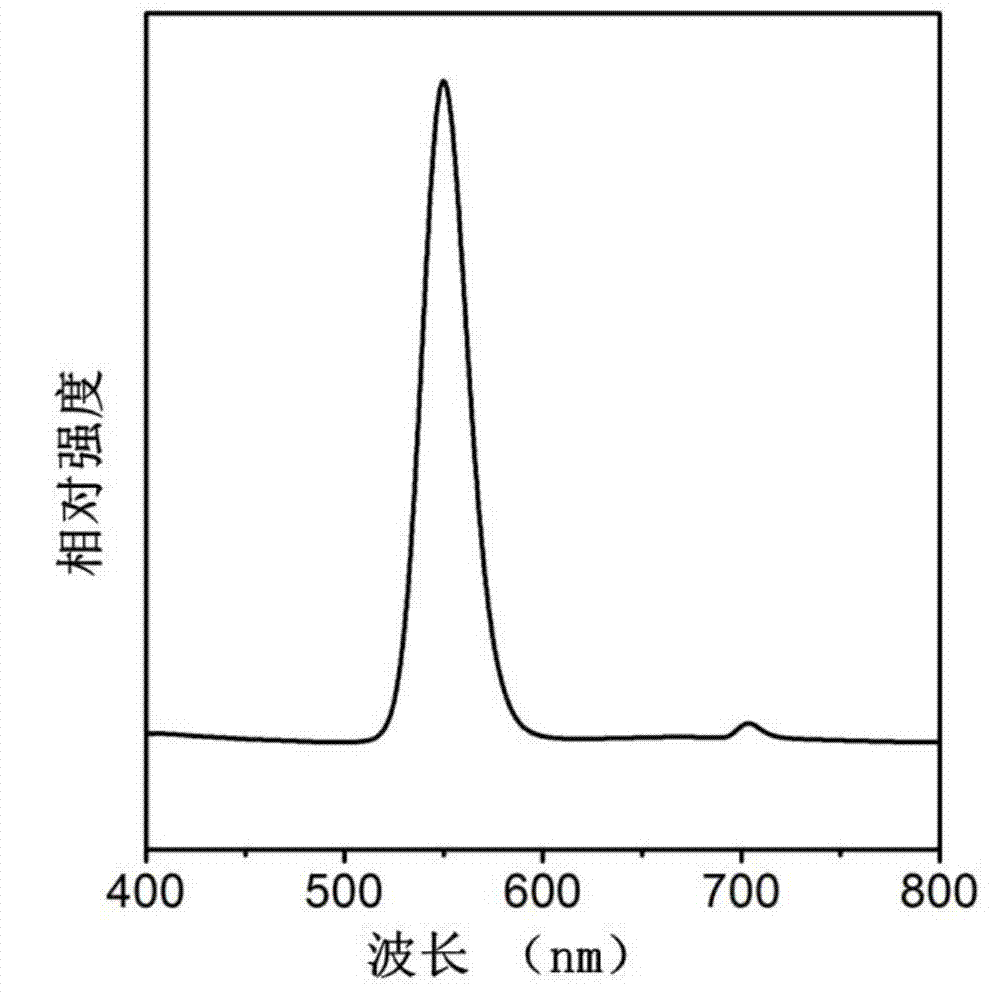

[0019] Put 0.20mmol cadmium stearate and 0.05mmol selenium powder into a three-necked bottle containing 20mL octadecene at room temperature, so that the concentration of cadmium stearate is 10mmol / L, and install a condensation reflux device for the three-necked bottle. Pass inert gas, and cycle vacuum 5 times to remove excess moisture and air. Under the protection of inert gas, the temperature was raised to 200°C, and the reaction was carried out at 200°C for 60 minutes. The reaction was stopped, and the cooling rate was controlled to be 5°C / min. The crude product was centrifuged at 10,000 r / min in a high-speed centrifuge, and the lower precipitate was collected. Then mix the precipitate with isopropanol solution, continue to centrifuge with a high-speed centrifuge at 10,000 r / min, and collect the lower layer of precipitate. The precipitate was dissolved in toluene solvent to obtain CdSe nanocrystal assembly with narrow size distribution. UV-Vis absorption spectra of nanocr...

Embodiment 2

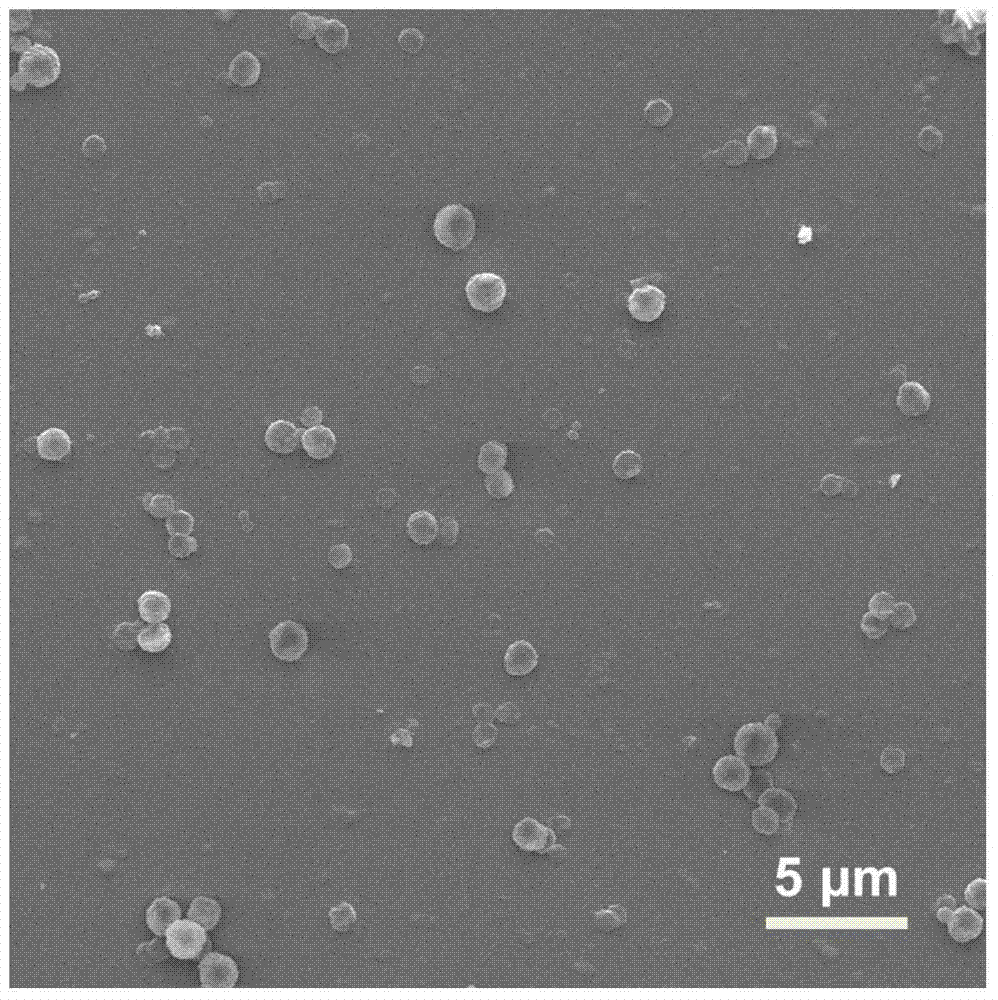

[0021] Put 0.15mmol cadmium stearate and 0.05mmol selenium powder into a three-necked bottle containing 10mL octadecene at room temperature, so that the concentration of cadmium stearate is 15mmol / L, and install a condensation reflux device for the three-necked bottle. Pass inert gas, and cycle vacuum 5 times to remove excess moisture and air. Under the protection of inert gas, the temperature was raised to 250°C, and the reaction was carried out at 250°C for 30 minutes. Stop the reaction, and control the cooling rate to 15°C / min. The crude product was centrifuged at 10,000 r / min in a high-speed centrifuge, and the lower precipitate was collected. Then mix the precipitate with isopropanol solution, continue to centrifuge with a high-speed centrifuge at 10,000 r / min, and collect the lower layer of precipitate. The precipitate was dissolved in toluene solvent to obtain CdSe nanocrystal assembly with narrow size distribution. The resulting SEM image of the nanocrystalline asse...

Embodiment 3

[0023] Put 0.10mmol cadmium stearate and 0.05mmol selenium powder into a three-necked bottle containing 5mL of octadecene at room temperature, so that the concentration of cadmium stearate is 20mmol / L, and install a condensation reflux device for the three-necked bottle. Pass inert gas, and cycle vacuum 5 times to remove excess moisture and air. Under the protection of inert gas, the temperature was raised to 300°C, and the reaction was carried out at 300°C for 10 minutes. The reaction was stopped, and the cooling rate was controlled to be 30°C / min. The crude product was centrifuged at 10,000 r / min in a high-speed centrifuge, and the lower precipitate was collected. Then mix the precipitate with isopropanol solution, continue to centrifuge with a high-speed centrifuge at 10,000 r / min, and collect the lower layer of precipitate. The precipitate was dissolved in toluene solvent to obtain CdSe nanocrystal assembly with narrow size distribution. The resulting SEM image of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com