Method and device for improving ammoxidation rate of nitric acid manufacture

A technology of ammonia oxidation rate and nitric acid, which is applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of low ammonia oxidation rate, catalyst poisoning, and lower ammonia purification degree, so as to improve ammonia oxidation rate and facilitate inspection and maintenance , Improve the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

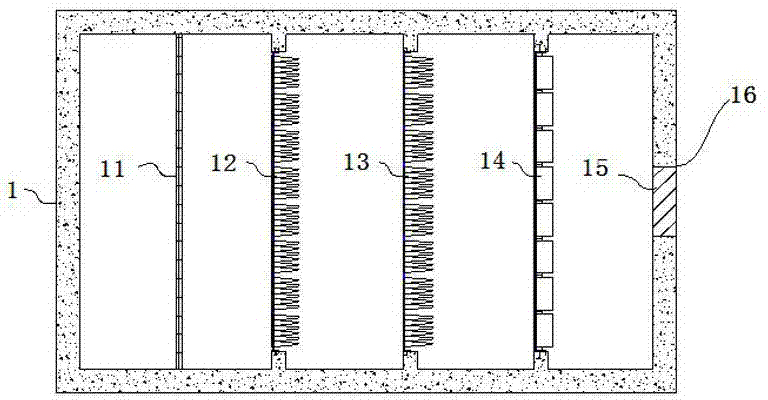

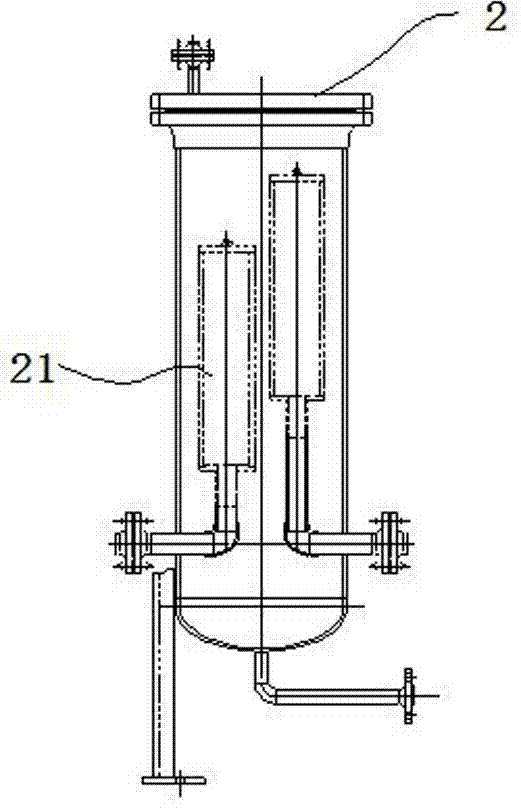

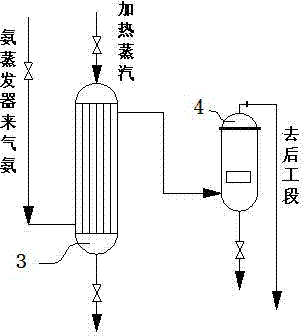

[0037] Such as Figure 1 to Figure 6Shown: a method for improving the ammonia oxidation rate of nitric acid production, including the following steps, 1) Air filtration: air filtration adopts air purification four-stage dry filtration, selects non-brittle fibers of different thicknesses and dust-removing adhesives with different Filling filter elements, the first stage is made of stainless steel wire mesh, the second and third stage filter elements are made of waterproof ES fiber non-woven fabric, and the material of the fourth stage filter element is made of waterproof polypropylene, which is filled in layers to form a stepped dust filtering method; through the air outlet surface 16 The air outlet goes to the compressor inlet, and the air outlet surface 16 is equipped with an air outlet filter screen 15 to reinforce and prolong the service life, which not only ensures stable filtration efficiency and dust holding capacity, but also increases the strength and reduces the use an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com