Processing technology for porcelain tile

A processing technology and technology of porcelain bricks, applied in the field of building materials, can solve the problems of low flexural strength of fired brick products, low recovery rate of cinder, low whiteness of fired brick products, etc., to improve ball milling efficiency and fluidity Good, the effect of reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

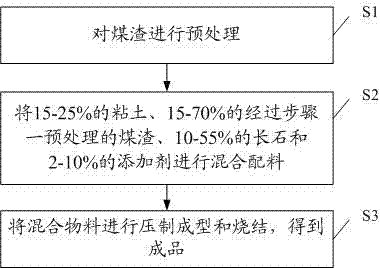

Method used

Image

Examples

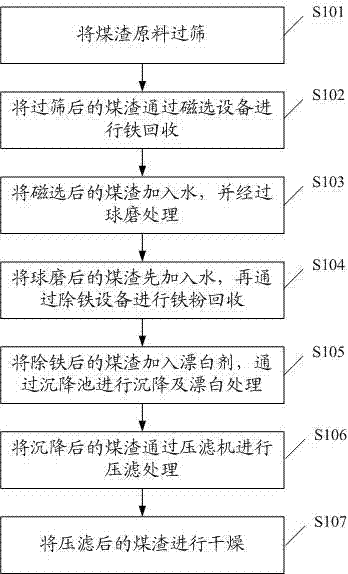

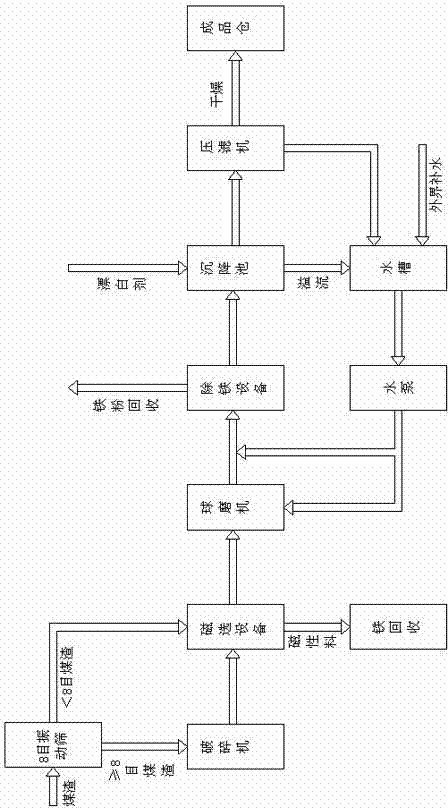

Embodiment 1

[0110] (1) Pretreatment of coal cinders: pass 130g of coal cinder raw materials through 8-mesh sieve; 107g of <8-mesh coal cinders enter the magnetic separation equipment for iron recovery, and 23g of ≧8-mesh coal cinders are crushed by a crusher, and then enter the magnetic separation equipment Carry out iron recovery, the recovered iron is 30g; 100g of coal slag after magnetic separation is added with 50g of water, and after ball milling, the first mixed material with a specific gravity of 1.0, a water content of 25%, and a flow rate of 10s is obtained; 150g of the first mixed material Add 80g of water to the material first, then reclaim the iron powder through the iron removal equipment to obtain the second mixed material with a specific gravity of 1.0, a water content of 25%, and a flow rate of 8s. The iron powder recovered is 5g; Add the mixture of 1g soda ash and 1g hydrosulfite to the second mixed material, carry out sedimentation and bleaching treatment through the sett...

Embodiment 2

[0114] (1) Pretreatment of coal cinders: pass 130g of coal cinder raw materials through 8-mesh sieve; 107g of <8-mesh coal cinders enter the magnetic separation equipment for iron recovery, and 23g of ≧8-mesh coal cinders are crushed by a crusher, and then enter the magnetic separation equipment Carry out iron recovery, the recovered iron is 30g; 100g of coal slag after magnetic separation is added with 50g of water, and after ball milling, the first mixed material with a specific gravity of 1.2, a water content of 30%, and a flow rate of 12s is obtained; 150g of the first mixed material Add 80g of water to the material first, and then reclaim the iron powder through the iron removal equipment to obtain the second mixed material with a specific gravity of 1.2, a water content of 30%, and a flow rate of 10s. The iron powder recovered is 5g; Add 3g of sulfuric acid to the second mixed material, the concentration of sulfuric acid is 20%, carry out sedimentation and bleaching treat...

Embodiment 3

[0118] (1) Pretreatment of coal cinders: pass 130g of coal cinder raw materials through 8-mesh sieve; 107g of <8-mesh coal cinders enter the magnetic separation equipment for iron recovery, and 23g of ≧8-mesh coal cinders are crushed by a crusher, and then enter the magnetic separation equipment Carry out iron recovery, the recovered iron is 30g; 100g of cinder after magnetic separation is added with 50g of water and 10g of raw talc, and after ball milling, the first mixed material with a specific gravity of 1.5, a water content of 35%, and a flow rate of 15s is obtained; 160g Add 80g of water to the first mixed material, and then reclaim the iron powder through the iron removal equipment to obtain the second mixed material with a specific gravity of 1.5, a water content of 40%, and a flow rate of 12s. The iron powder recovered is 5g; the 235g Add the mixture of 1g soda ash and 2g hydrosulfite to the second mixed material after iron removal, carry out sedimentation and bleachin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com