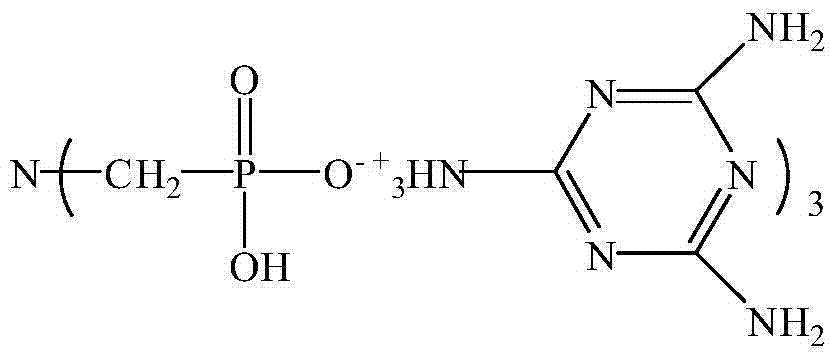

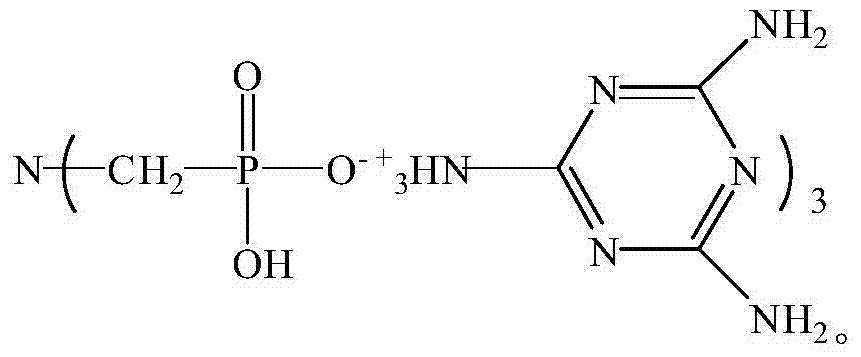

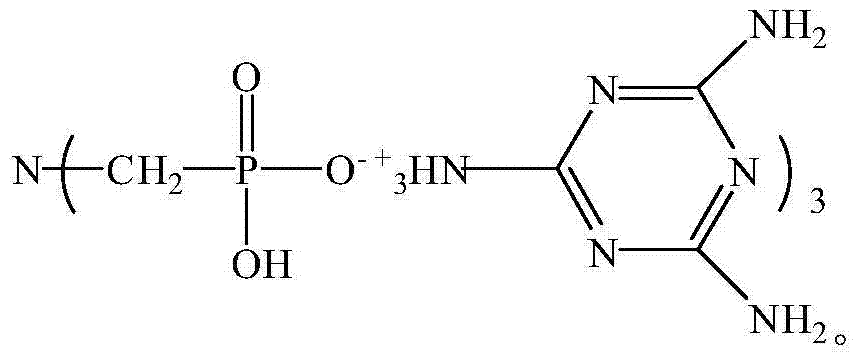

Melamine aminotrimethylene phosphonate and preparation method thereof

A technology of melamine amino trimethylene phosphonate and polycyanamide amino trimethylene phosphonate is applied in the field of melamine amino trimethylene phosphonate and its preparation, and can solve the problem of unsatisfactory flame retardant effect of polyolefin and hindering resistance. Influence of the charring effect of the burning agent, poor charring of the flame retardant, etc., to achieve the effects of low toxic thermal decomposition temperature, excellent flame retardant performance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 12.6g of melamine into a reaction kettle with a stirring device, add 1000ml of deionized water, raise the temperature at 50°C and stir to obtain a completely dissolved melamine solution, then dissolve 29.9g of aminotrimethylenephosphonic acid in deionized water, and gradually added dropwise to the reaction kettle, kept warm for 2 hours, filtered, washed, and dried to obtain a white solid powder.

Embodiment 2

[0025] Put 12.6g of melamine into a reaction kettle with a stirring device, add 1500ml of deionized water, raise the temperature at 55°C and stir to obtain a completely dissolved melamine solution, then dissolve 29.9g of aminotrimethylene phosphonic acid in deionized water, and gradually added dropwise to the reaction kettle, kept warm for 2.5 hours, filtered, washed, and dried to obtain a white solid powder.

Embodiment 3

[0027] Put 18.9g of melamine into a reaction kettle with a stirring device, add 1100ml of deionized water, raise the temperature at 60°C and stir to obtain a completely dissolved melamine solution, then dissolve 29.9g of aminotrimethylene phosphonic acid in deionized water, and gradually added dropwise to the reaction kettle, kept warm for 3 hours, filtered, washed, and dried to obtain a white solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com