Flame-retardant polycarbonate composition and preparation method thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of engineering plastics, can solve the problems of difficulty in dispersing flame retardants, degradation of flame-retardant properties of materials, and easy addition of additives, etc., to solve surface flushing and pitting , Solve the unstable flame retardant performance, solve the effect of unsatisfactory flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

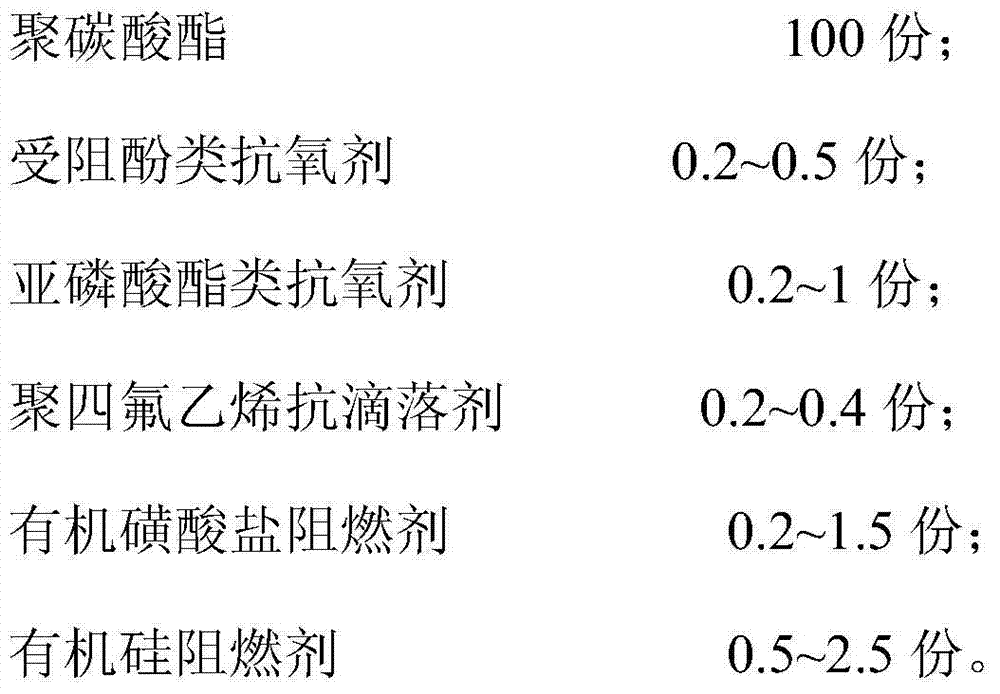

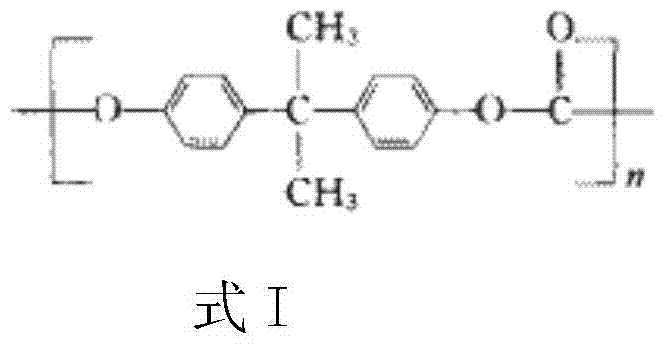

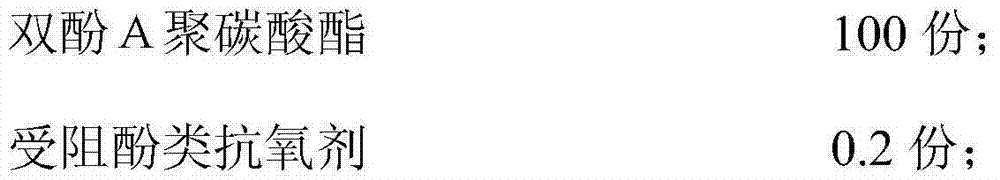

[0051] Embodiment 1: The flame retardant polycarbonate composition of this embodiment includes the following components in parts by mass: .

[0052]

[0053]

[0054] The method for preparing the above-mentioned flame-retardant polycarbonate composition comprises the following steps:

[0055] Premixing: in parts by mass, 100 parts of bisphenol A polycarbonate, 0.2 part of hindered phenolic antioxidant, 0.4 part of phosphite antioxidant, 0.3 part of pentaerythritol tetrastearate, SAN-coated polytetrafluoroethylene Put 0.3 parts of vinyl fluoride, 0.4 parts of potassium diphenyl sulfone sulfonate and 1.0 parts of organosiloxane flame retardant into a mixer and stir for 4 minutes to mix evenly to prepare a mixture;

[0056] Melt mixing: put the mixture into a special screw combination co-rotating twin-screw extruder with a length-to-diameter ratio of 40:1, and heat up each temperature zone to 270-280°C for melting to obtain a melt blend;

[0057] Cooling granulation: extru...

Embodiment 2

[0058] Embodiment 2: The flame retardant polycarbonate composition of this embodiment includes the following components in parts by mass: .

[0059]

[0060] The method for preparing the above-mentioned flame-retardant polycarbonate composition comprises the following steps:

[0061] Premixing: in parts by mass, 100 parts of bisphenol A polycarbonate, 0.2 part of hindered phenolic antioxidant, 0.4 part of phosphite antioxidant, 0.3 part of pentaerythritol tetrastearate, SAN-coated polytetrafluoroethylene Put 0.3 parts of vinyl fluoride, 0.48 parts of potassium diphenyl sulfone sulfonate and 0.92 parts of organosiloxane flame retardant into a mixer and stir for 4 minutes to mix evenly to prepare a mixture;

[0062] Melt mixing: put the mixture into a special screw combination co-rotating twin-screw extruder with a length-to-diameter ratio of 40:1, and heat up each temperature zone to 270-280°C for melting to obtain a melt blend;

[0063] Cooling granulation: extruding the m...

Embodiment 3

[0064] Embodiment 3: The flame-retardant polycarbonate composition of this embodiment includes the following components in parts by mass: .

[0065]

[0066] The method for preparing the above-mentioned flame-retardant polycarbonate composition comprises the following steps:

[0067] Premixing: in parts by mass, 100 parts of bisphenol A polycarbonate, 0.2 part of hindered phenolic antioxidant, 0.4 part of phosphite antioxidant, 0.3 part of pentaerythritol tetrastearate, SAN-coated polytetrafluoroethylene Put 0.3 part of vinyl fluoride, 0.5 part of potassium diphenylsulfone sulfonate and 0.9 part of organosiloxane flame retardant into a mixer and stir for 4 minutes to mix evenly to prepare a mixture;

[0068] Melt mixing: put the mixture into a special screw combination co-rotating twin-screw extruder with a length-to-diameter ratio of 40:1, and heat up each temperature zone to 270-280°C for melting to obtain a melt blend;

[0069] Cooling granulation: extruding the melted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com