Method for extracting okra seed oil

An okra seed extraction technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of high extraction cost, solvent residue, and peculiar smell, and achieve the effect of short extraction cycle, low solvent consumption, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

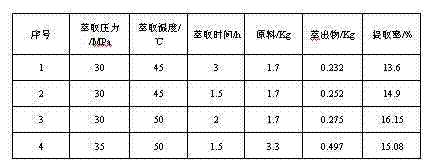

[0016] The implementation method is as follows: choose dry okra seeds with smooth surface as raw materials, put the okra seeds into an oven, and dry the okra seeds at a temperature of 55°C for 12 hours; put the pre-dried okra seeds into a grinder and grind them into 28 Purpose sunflower seed powder; then put the sunflower seed powder into an oven, and dry the sunflower seed powder at a temperature of 55°C for 12 hours; the sunflower seed powder after drying continues to be left in the drying furnace to cool naturally to normal temperature; Put 1.7kg of the final sunflower seed powder into the material bucket of the extraction kettle, inject carbon dioxide gas into the extraction kettle for extraction, the extraction temperature is 45°C, and the pressure is 30MPa; the flow rate of carbon dioxide gas through the extraction kettle is 220kg / h, and the extraction time is 1.5h, the okra seed oil component in the sunflower seed powder was dissolved in the supercritical fluid, and the ...

Embodiment 3

[0018] The implementation method is as follows: choose dry okra seeds with a smooth surface as raw materials, put the okra seeds into an oven, and dry the okra seeds for 12 hours at a temperature of 60°C; put the pre-dried okra seeds into a grinder and grind them into 22 Purpose sunflower powder; then put the sunflower powder into an oven, and dry the sunflower powder at 60°C for 12 hours; the dried sunflower powder continues to be left in the drying furnace to cool naturally to normal temperature; Put 1.7kg of the final sunflower seed powder into the material bucket of the extraction kettle, inject carbon dioxide gas into the extraction kettle for extraction, the extraction temperature is 50°C, and the pressure is 30MPa; the flow rate of carbon dioxide gas through the extraction kettle is 250kg / h, and the extraction time is 2h, the okra seed oil component in the sunflower seed powder is dissolved in the supercritical fluid, and the fluid containing the okra seed oil is collect...

Embodiment 4

[0020] The implementation method is as follows: choose dry, smooth surface okra seeds as raw materials, put the okra seeds into an oven, and dry the okra seeds at a temperature of 60°C for 12 hours; put the pre-dried okra seeds into a grinder and grind them into 20 Purpose sunflower powder; then put the sunflower powder into an oven, and dry the sunflower powder at 60°C for 12 hours; the dried sunflower powder continues to be left in the drying furnace to cool naturally to normal temperature; Put 3.3kg of the final sunflower seed powder into the material bucket of the extraction kettle, inject carbon dioxide gas into the extraction kettle for extraction, the extraction temperature is 50°C, and the pressure is 35MPa; the flow rate of carbon dioxide gas through the extraction kettle is 250kg / h, and the extraction time is 1.5h, the okra seed oil component in the sunflower seed powder was dissolved in the supercritical fluid, and the fluid containing the okra seed oil was collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com