Low aluminum compound deoxidizer

A deoxidizer and aluminum composite technology, applied in the field of metallurgy, can solve the problems of inconvenient storage and transportation, excessive consumption of raw materials, and easy oxidation of alkali metals, etc., and achieve the effects of low cost, easy collision growth, and easy melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

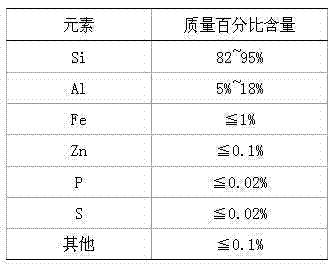

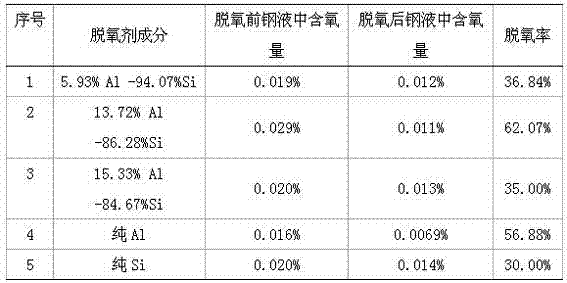

[0012] The composition of the Si-Al composite deoxidizer for stainless steel prepared according to the method of the present invention is 6%Al, 94%Si, and other elements are restricted as shown in Table 1.

[0013] The preparation method is as follows: use industrial silicon and industrial pure aluminum as raw materials, calculate the required raw materials according to the configuration requirements, melt them in an electric furnace, and then take them out of the furnace, and cast them into block deoxidizer ingots with different sizes according to the needs of users. In the deoxidation process of stainless steel and aluminum-killed steel, the deoxidizer is directly put into molten steel to complete the deoxidation process. The input amount is determined according to the initial oxygen content in molten steel and the amount of molten steel. The amount added is generally 0.5-2 kg / t molten steel.

[0014] Table 1: Composition list of Si-Al composite deoxidizer for stainless ste...

Embodiment 2

[0017] The composition of the Si-Al composite deoxidizer for stainless steel prepared according to the method of the present invention is 13% Al, 86% Si, and other elements are restricted as shown in Table 1.

[0018] The preparation method is the same as in Example 1.

Embodiment 3

[0020] The composition of the Si-Al composite deoxidizer for stainless steel prepared according to the method of the present invention is 16% Al, 84% Si, and other elements are restricted as shown in Table 1.

[0021] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com