Chromium reducing method based on iron-containing sulphide ore under action of acidophilic bacteria

A technology of acidophilic bacteria and sulfide minerals, applied in the direction of improving process efficiency, can solve the problems of restricting large-scale industrial application, low utilization rate of reducing substrates, low microbial reduction and remediation treatment efficiency, etc., and achieve large-scale industrialization. Use, speed up reduction reaction kinetics, overcome the effect of low utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method described in this example mainly includes the following steps:

[0038] 1) Expand Acidithiobacillus ferrooxidans in 9K medium containing 10g / L sulfur powder. The initial pH value is 2.0, and the culture temperature is 30°C. Filter the solid-liquid separation until it enters the logarithmic culture period, and the bacterial liquid passes through 12000rpm Collect by centrifugation for 10 minutes;

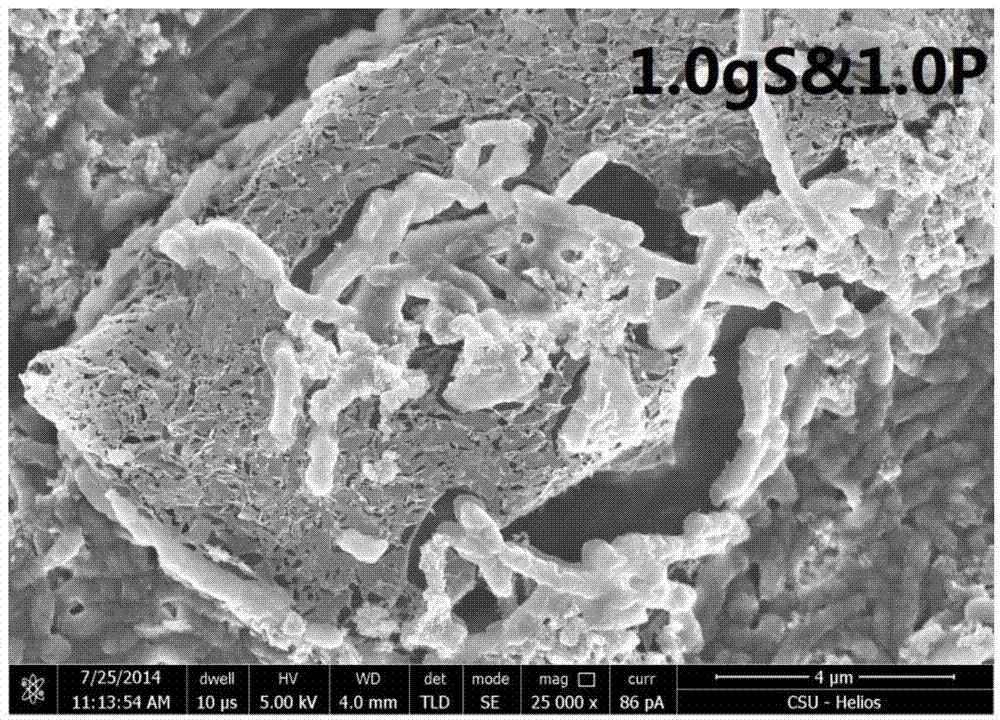

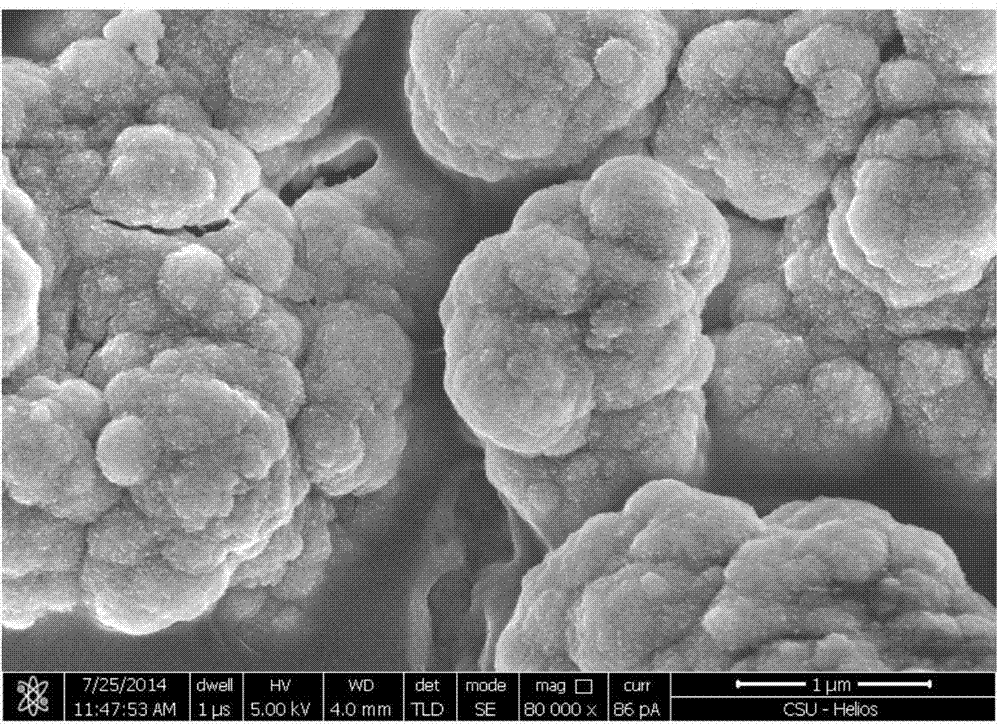

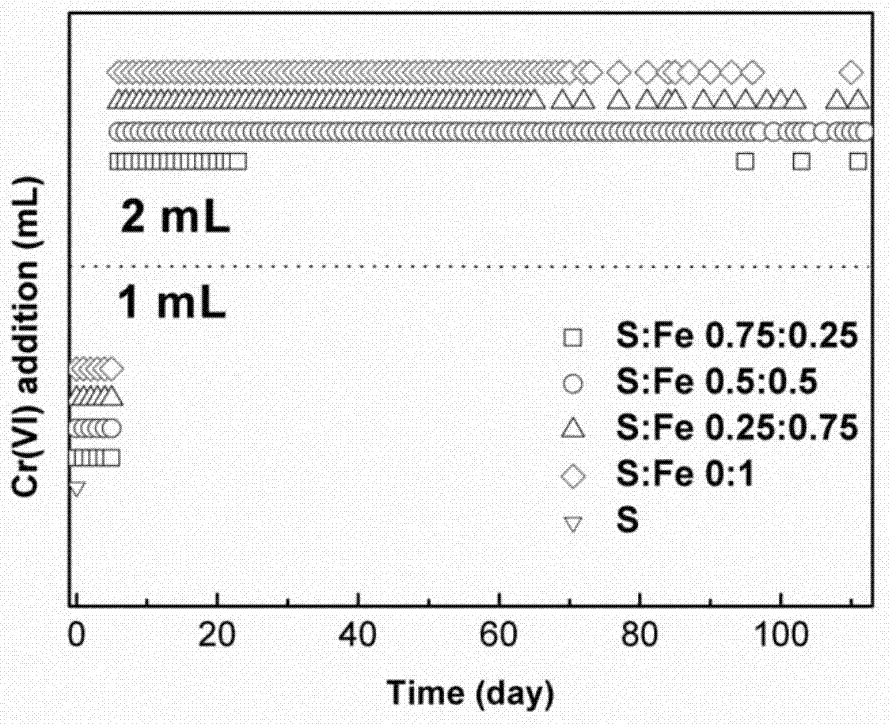

[0039] 2) Inoculate the collected Acidithiobacillus ferrooxidans into the 250mL shake flask system containing sulfur powder and pyrite ratio of 2.0g:0g, 1.5g:0.5g, 1g:1g; 0.5g:1.5g, 0g:2g, The concentration of bacteria after inoculation was 1.0×10 7 / mL, the particle size of pyrite is 200 mesh, the volume of Erlenmeyer flask is 250mL, the reaction volume is 100mL, the concentration of ore pulp is 2%, pre-oxidize to pH below 1, and add Cr(VI) solution (1000mg / L) to it. The dosage is 1mL per day, and it will be increased to 2mL per day in the later period. The dosage...

Embodiment 2

[0043] Carry out continuous fed-batch treatment in the column leaching reactor, the method described in this instance mainly comprises the following steps:

[0044] 1) Acidithiobacillus ferrooxidans was expanded in 9K medium containing 10g / L sulfur powder, the initial pH value was 2.0, and the culture temperature was 30°C. When it entered the logarithmic culture period, the solid-liquid separation was carried out by filtration, and the bacterial liquid was used for later use;

[0045] 2) Pyrite particles are filled in the column leaching reactor, and the pyrite particle size is less than 0.5cm particles; the chromium solution to be treated is pre-adjusted to about 3 with concentrated sulfuric acid, and flows into the column leaching reactor from the upper part of the reactor to control Reasonable flow rate to make it react completely. If the reaction is complete, pump the remaining liquid to the post-sedimentation tank.

[0046] 3) When the reduction ability of the pyrite chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com