Quaternized chitosan HTCC/CA/TiO2 hybrid membrane, and preparation method thereof

A technology of quaternized chitosan and hybrid membrane, applied in the field of membrane separation, can solve the problems of unsatisfactory mechanical properties, poor mechanical strength, high swelling degree, and achieve good antibacterial ability, improved antibacterial performance, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

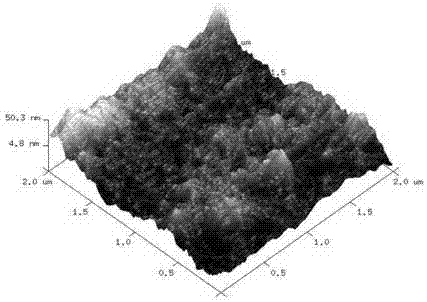

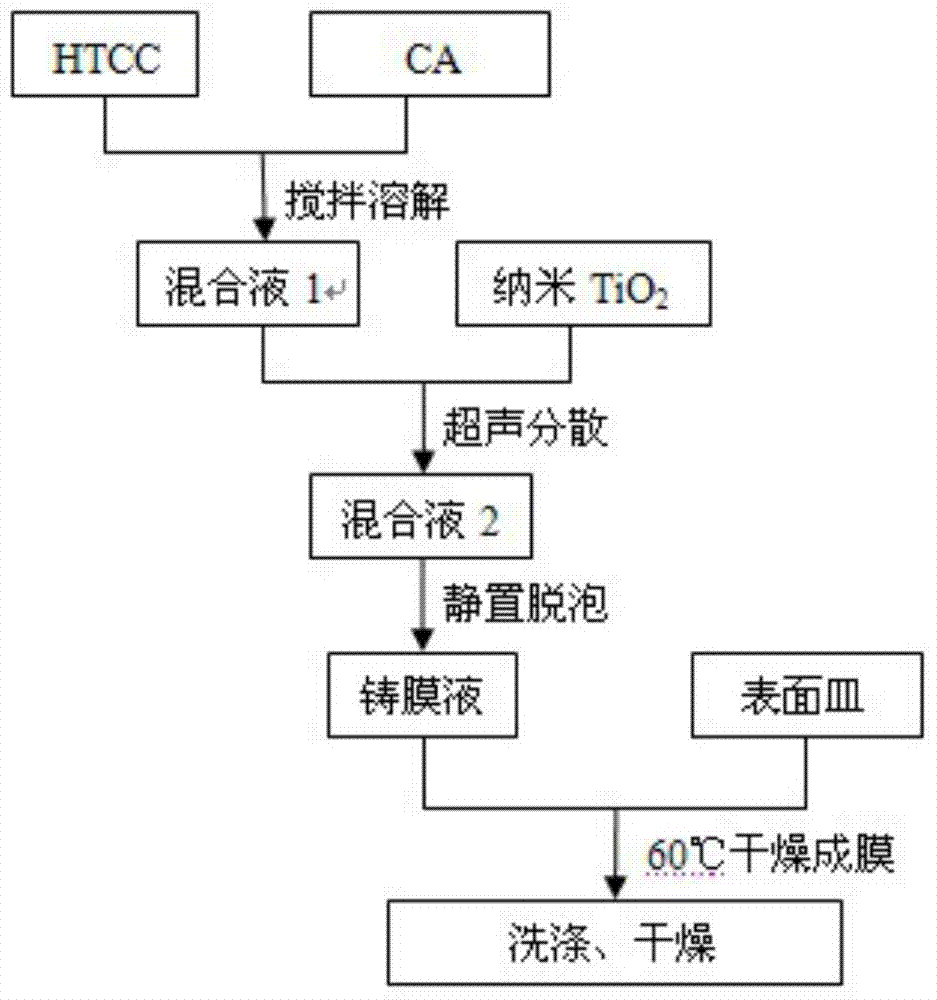

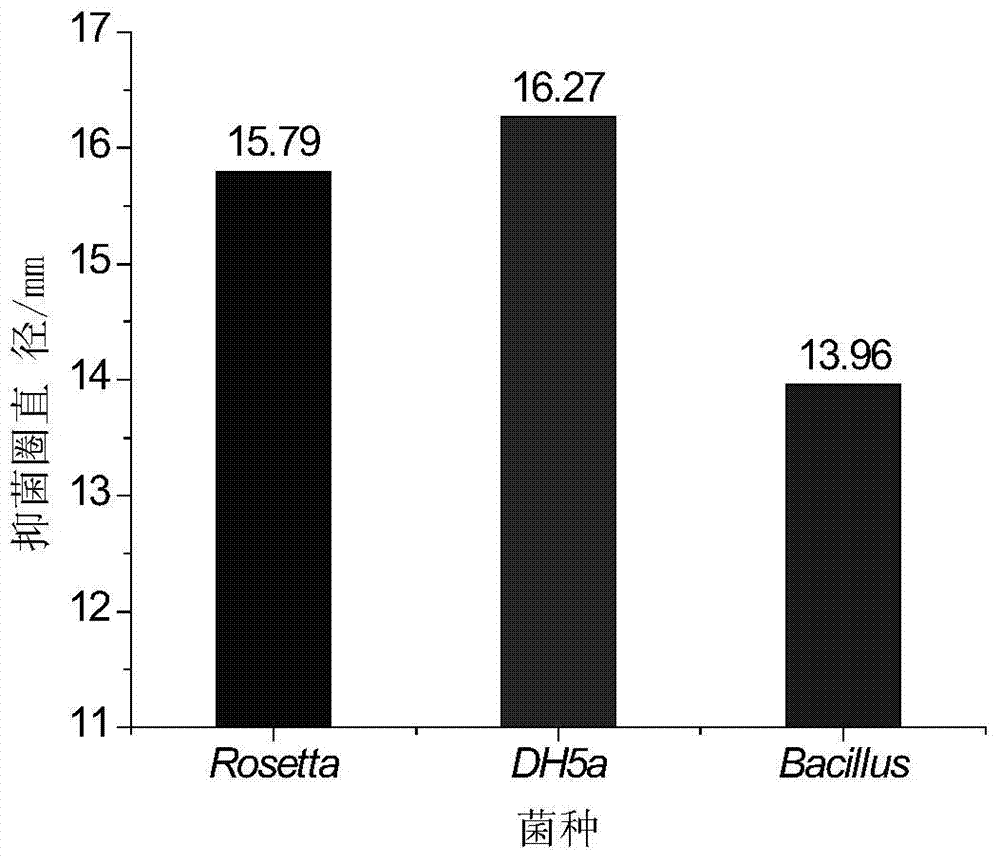

[0027] Example 1: Weigh quantitative HTCC and CA respectively according to a blending ratio of 1:1 and place them in a 150mL beaker, add a 70% aqueous solution of acetic acid, and keep stirring until HTCC and CA are completely dissolved, and the mass concentration is 2% mixture. Then add nano-TiO with a mass fraction of 0.5% to the mixture 2 , through ultrasonic dispersion (KQ-100PE ultrasonic dispersion machine), the TiO in the casting solution 2 The particles are evenly dispersed, and after standing for defoaming under vacuum conditions, pour the casting solution into a watch glass and dry at 50°C to form a film. Finally, the prepared membrane was soaked in 0.1mol / L NaOH solution for 1 hour, then washed with deionized water until the water became neutral, and then dried naturally at room temperature for determination.

[0028] Prepared HTCC / CA / TiO 2 The mechanical strength of the hybrid membrane is 59.69MPa, the elongation at break is 41.43%, the swelling degree is 109.05...

Embodiment 2

[0029] Embodiment 2: Weigh quantitative HTCC and CA respectively according to the blending ratio of 1:1 and place it in a 150mL beaker, add a 70% aqueous solution of acetic acid, and keep stirring until HTCC and CA are completely dissolved, and the mass concentration is 2% mixture. Then add nano-TiO with a mass fraction of 1.0% to the mixture 2 , through ultrasonic dispersion (KQ-100PE ultrasonic dispersion machine), the TiO in the casting solution 2 The particles are evenly dispersed, and after standing for defoaming under vacuum conditions, pour the casting solution into a watch glass and dry at 60°C to form a film. Finally, the prepared membrane was soaked in 0.1mol / L NaOH solution for 1 hour, then washed with deionized water until the water became neutral, and then dried naturally at room temperature for determination.

[0030] Prepared HTCC / CA / TiO 2 The mechanical strength of the hybrid membrane is 84.29MPa, the elongation at break is 55.12%, the swelling degree is 101...

Embodiment 3

[0031] Example 3: Take quantitative HTCC and CA according to the blending ratio of 1:1 and place them in a 150mL beaker, add a 70% aqueous solution of acetic acid, and keep stirring until HTCC and CA are completely dissolved, and the mass concentration is 2% mixture. Then add nano-TiO with a mass fraction of 1.5% to the mixture 2 , through ultrasonic dispersion (KQ-100PE ultrasonic dispersion machine), the TiO in the casting solution 2The particles are evenly dispersed, and after standing for defoaming under vacuum conditions, pour the casting solution into a watch glass and dry at 60°C to form a film. Finally, the prepared membrane was soaked in 0.1mol / L NaOH solution for 1 hour, then washed with deionized water until the water became neutral, and then dried naturally at room temperature for determination.

[0032] Prepared HTCC / CA / TiO 2 The mechanical strength of the hybrid membrane is 63.86MPa, the elongation at break is 49.11%, the swelling degree is 122.83%, and the io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Ion exchange capacity | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com