Quantum dot film

A technology of quantum dot film and quantum dot layer, applied in the directions of polymer adhesive additives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of unsatisfactory heat resistance of the bonding layer , Reduce the high color gamut stability of the quantum dot film display screen, and achieve the effect of good optical transparency, brightness and color saturation not easy to decline, and good optical characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method for preparing optical adhesive and attaching quantum dot film:

[0045] 1) Mix the materials according to the ratio in Table 1, stir and mix to form an optical adhesive;

[0046] 2) Configure the quantum dot coating solution containing red / green quantum dots, silica gel particles, diffusion particles, adhesives, additives and solvents; coat quantum dots on the smooth surface of the substrate with water and oxygen barrier protection layer, cured to form a film for later use.

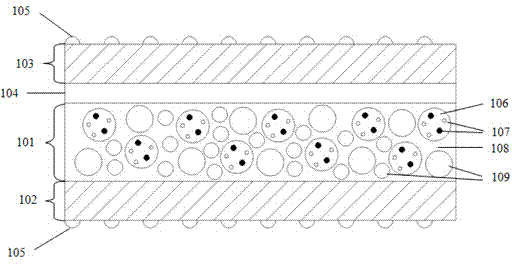

[0047] 3) Coating the prepared optical adhesive on the quantum dot layer obtained in the previous step, with the thickness controlled at 15±5 μm. Bond the smooth surface of the substrate with water and oxygen barrier protection, heat and cure at 80°C under air-isolated conditions, and obtain the quantum dot film bonded with the optical adhesive. Its structure is as follows: figure 1 As shown, the test results are shown in Table 8.

[0048] Table 1 The ratio of the optical adhesive use...

Embodiment 2

[0051] The quantum dot film was prepared according to the method of Example 1, the difference being that the optical adhesive was prepared using the ratio shown in Table 2.

[0052] Table 2 The ratio of the optical adhesive used in Example 2

[0053]

[0054]

Embodiment 3

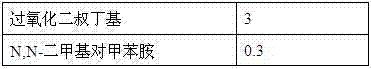

[0056] The quantum dot film was prepared according to the method of Example 1, the difference being that the optical adhesive was prepared using the ratio shown in Table 3.

[0057] Table 3 The ratio of the optical adhesive used in Example 3

[0058]

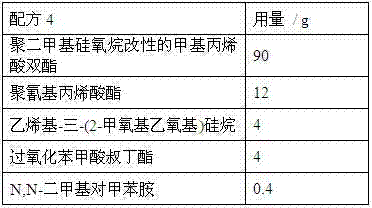

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com