Absorbent for collecting carbon dioxide

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, dispersed particle separation, air quality improvement, etc., can solve the problems of high energy consumption and low absorption capacity of absorbent, and achieve low energy consumption and high absorption capacity for desorption. , the effect of fast absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This example discloses seven absorbents for capturing carbon dioxide, all of which are composed of an aqueous solution of 1-amino-4-(2-hydroxyethyl)-piperazine. The 1-amino-4-(2-hydroxyethyl The mass concentration of base)-piperazine is respectively 10%, 20%, 25%, 30%, 40%, 50% and 70%.

[0048] In a glass reactor placed in a constant temperature water bath (40°C), add the above-mentioned seven kinds of absorbents for capturing carbon dioxide respectively, and feed them with a volume composition of 14% CO under normal pressure. 2 , 86%N 2 mixed gas, while the absorption liquid was stirred at a constant temperature of 40°C. Gas chromatography (Agilent 7890B) was used to analyze CO in the outlet gas of the reactor. 2 concentration, when its concentration is the same as that of the imported CO 2 When the concentration is equal, the absorbent has reached the saturated absorption capacity. Then, the air intake was stopped, while the temperature of the water bath was kept...

Embodiment 2

[0051] This example discloses eight absorbents for capturing carbon dioxide, all of which are composed of 1-amino-4-(2-hydroxyethyl)-piperazine and compounds capable of adjusting absorption rate and absorption capacity. Among them, the above-mentioned eight kinds of absorbents for capturing carbon dioxide use the compound with the function of adjusting the absorption rate and absorption capacity and 1-amino-4-(2-hydroxyethyl)-piperazine and the compound with the function of adjusting the absorption rate and absorption capacity The weight ratios of the functional compounds are shown in the table below:

[0052]

[0053] The preparation methods are as follows: dissolving 1-amino-4-(2-hydroxyethyl)-piperazine and compounds with the function of adjusting absorption rate and absorption capacity in water to prepare an aqueous solution with a total mass concentration of 30%.

[0054] In a glass reactor placed in a constant temperature water bath (40°C), add the above-mentioned eig...

Embodiment 3

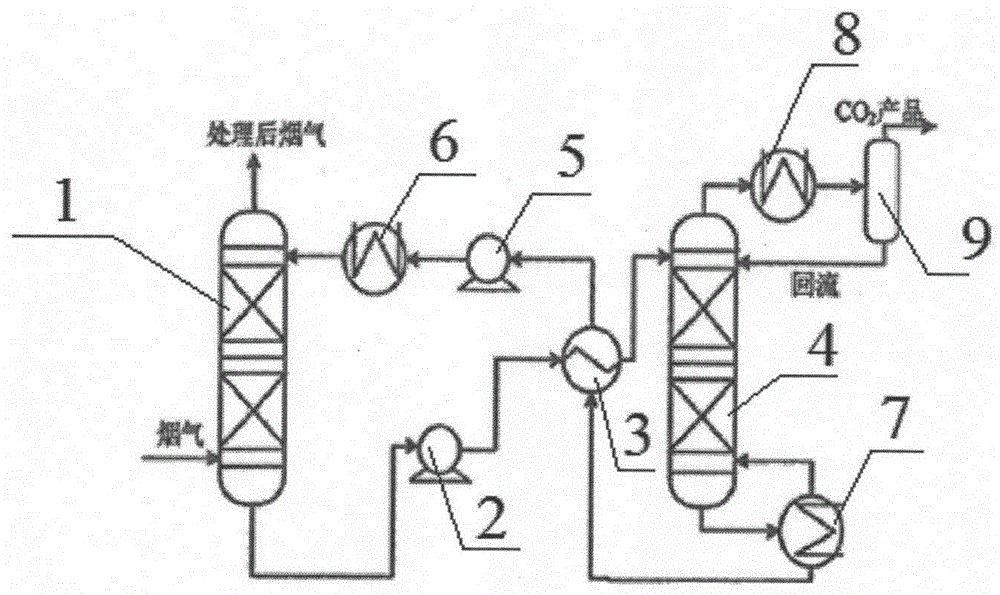

[0056] Absorbent of the present invention is applied to such as figure 1 In the shown Shanghai boiler flue gas carbon dioxide recovery pilot plant, the process of the plant is conventional CO 2 Absorption and desorption process, the absorption tower 1 is sprayed with the first absorbent for capturing carbon dioxide in Example 2, the boiler flue gas is absorbed by the absorbent to form treated flue gas, and the absorption liquid that has absorbed carbon dioxide is passed through the rich The liquid pump 2 and the lean / rich liquid heat exchanger 3 enter the desorption tower 4, and form CO after desorption 2 product, the desorbed absorption liquid re-enters the absorption tower 1 after passing through the lean liquid pump 5 and the first cooler 6. Boiler flue gas, treated flue gas and CO 2 The composition of the product is shown in the table below. The average temperature of the absorption tower is 50°C, and the maximum temperature of the desorption tower is 106°C. CO 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com