A device and method for cleaning carbon dioxide in industrial waste gas by using microalgae

A carbon dioxide and clean industry technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of high corrosiveness, low selectivity, potential impact and hazards of the earth's crust, etc., so as to improve efficiency and avoid churn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

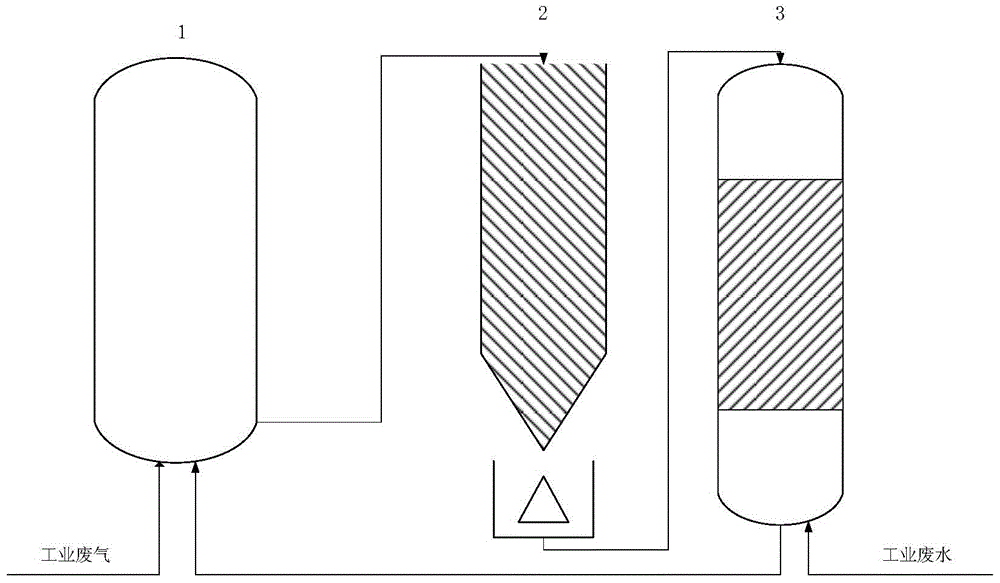

[0030] A device that uses microalgae to clean carbon dioxide in industrial waste gas. The photobioreactor uses a tubular microalgae culture system with suitable temperature and light. The culture liquid circulation system is coupled with a wastewater treatment device. Industrial wastewater was used as the culture solution, and the heat-resistant chlorella Chorella sp. was selected as the cultured microalgae.

[0031] The collection and production capacity system uses an air flotation device to settle and collect microalgae. The collection and production capacity system is also coupled with a microalgae utilization device, and the microalgae utilization device is composed of a microalgae hydrothermal reaction system and an anaerobic fermentation system. The microalgae hydrothermal reaction system includes a preheating system, a plug flow hydrothermal reactor, and a three-phase separation system.

[0032] The microalgae enrichment liquid is further utilized through a microalgae...

Embodiment 2

[0036]The photobioreactor of this embodiment uses a column type microalgae culture system with suitable temperature and light, and the microalgae is heat-resistant chlorella Chorella sp. The culture solution circulation system oxidizes the relevant inhibitory components in the treated steel mill wastewater, and adds trace elements and vitamins, injects them into the microalgae culture system with suitable temperature and light to mature, and then enters the collection and production capacity system for precipitation by the air flotation device. The precipitated microalgae are directly fed into the microalgae anaerobic fermentation system, and the anaerobic fermentation produces biogas. The water separated by the energy collection system enters the culture fluid circulation system, which can be recycled for the cultivation of microalgae, or recycled as industrial water.

Embodiment 3

[0038] The photobioreactor of this embodiment uses a column type microalgae culture system with suitable temperature and light, and the microalgae is heat-resistant chlorella Chorella sp. Inject the BG11 culture solution into a column microalgae culture system with suitable temperature and light. After the microalgae are matured in the culture system, they are passed into the collection and production capacity system and settled by the air flotation device. The collected microalgae are directly fed into the microalgae anaerobic fermentation system for anaerobic fermentation to produce biogas. The culture solution circulation system processes the culture solution separated by the collection and production system, eliminates the relevant inhibitory components, adds nutrients such as trace elements and vitamins, and circulates the culture solution back to the column microalgae cultivation system.

[0039] The microalgae in this example can effectively clean and utilize the carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com