Adsorbent for removing LDL and preparation method thereof

A technology of adsorbent and solvent, which is applied in the field of adsorbent for LDL removal and its preparation, can solve the problems of complex preparation method and low adsorption efficiency, and achieve the effects of simple process, improved adsorption performance and reduced safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

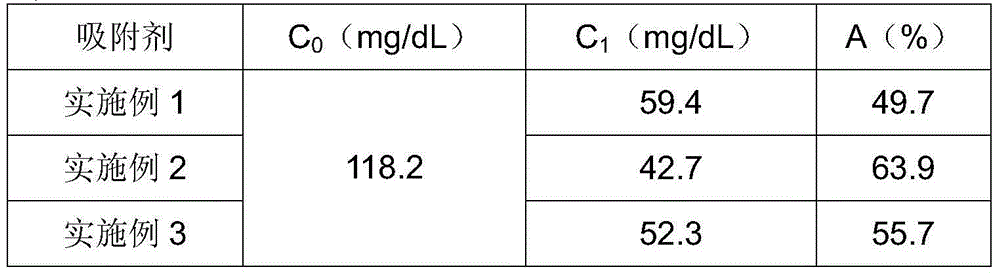

Embodiment 1

[0040] Add 1.5ml of ethanol and 0.5ml of deionized water to 8ml of tetrahydrofuran to obtain a mixed solution with a volume ratio of THF, ethanol and water of 8:1.5:0.5; accurately weigh 1.0mg of polyvinyl butyral, 0.10 of polyglutamic acid mg, sodium chloride 0.1mg, add the above mixed solution in turn while stirring, seal, and stir overnight at 25°C to obtain a clear and transparent spinning solution; inject the spinning solution into a 10ml syringe and connect a No. 5 stainless steel needle (inner diameter 0.5mm) , adjust the output voltage of the high-voltage power supply to 10kv, adjust the flow rate of the syringe pump to 0.8ml / h, and the receiving distance to 15cm, and use a grounded aluminum foil as the receiving device; after spinning, put the fiber membrane and the aluminum foil at the bottom together into a 60 ℃ in a vacuum drying oven, vacuum dry for 4 hours to fully evaporate the solvent; peel off the fiber membrane from the aluminum foil, add deionized water to so...

Embodiment 2

[0042] Add 3.0ml of ethanol and 1.0ml of deionized water to 6.0ml of tetrahydrofuran to obtain a mixed solution with a volume ratio of THF, ethanol and water of 6:3:1; accurately weigh 0.8mg of polyvinyl butyral, polyglutamic acid 0.15mg, sodium chloride 0.2mg, while stirring, add the above-mentioned mixed solution in sequence, seal, and stir overnight at 25°C to obtain a clear and transparent spinning solution; inject the spinning solution into a 10ml syringe, connect a No. 5 stainless steel needle (inner diameter 0.5mm ), adjust the output voltage of the high-voltage power supply to 16kv, adjust the flow rate of the syringe pump to 1.2ml / h, and the receiving distance to 20cm, use a grounded aluminum foil as the receiving device; after spinning, put the fiber membrane together with the aluminum foil at the bottom In a vacuum oven at 60°C, vacuum-dry for 4 hours to fully evaporate the solvent; peel off the fiber membrane from the aluminum foil, soak in deionized water and ultra...

Embodiment 3

[0044] Add 3ml of ethanol and 2ml of deionized water to 5ml of tetrahydrofuran to obtain a mixed solution with a volume ratio of THF, ethanol and water of 5:3:2; accurately weigh 0.6mg of polyvinyl butyral and 0.2mg of polyglutamic acid, Sodium chloride 0.20 mg, while stirring, add the above-mentioned mixed solution successively, seal, and stir overnight at 25 ° C to obtain a clear and transparent spinning solution; inject the spinning solution into a 10ml syringe, connect a No. 6 stainless steel needle (inner diameter 0.6mm), adjust The output voltage of the high-voltage power supply is 20kv, the flow rate of the syringe pump is adjusted to 1.5ml / h, the receiving distance is 25cm, and the grounded aluminum foil is used as the receiving device; after the spinning is completed, put the fiber membrane together with the aluminum foil at the bottom into a vacuum at 60°C In a drying oven, vacuum-dry for 4 hours to fully evaporate the solvent; peel the fiber membrane from the aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com