Preparation method for single crystal selenium nanorod visible light catalytic material and use thereof

A photocatalytic material, selenium nanotechnology, applied in the field of nanomaterials, can solve the problems of low utilization rate and achieve the effect of uniform shape, high photocatalytic rate and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method of the single crystal selenium nanorod visible light photocatalytic material t-Se NRs prepared in this example is as follows: (1) Preparation of amorphous α-Se

[0026] Weigh 0.111g SeO 2 , 0.352g of ascorbic acid were dissolved in 10mL of deionized water, after the dissolution was complete, the ascorbic acid solution was slowly added dropwise to the selenous acid solution. sex. Finally, the solid phase product obtained by centrifugation is α-Se.

[0027] (2) Preparation of single crystal gray selenium t-Se NRs

[0028] The prepared α-Se was then transferred to a beaker filled with ethanol, left to age for 24 hours, washed and dried to obtain a gray product, which was t-Se NRs.

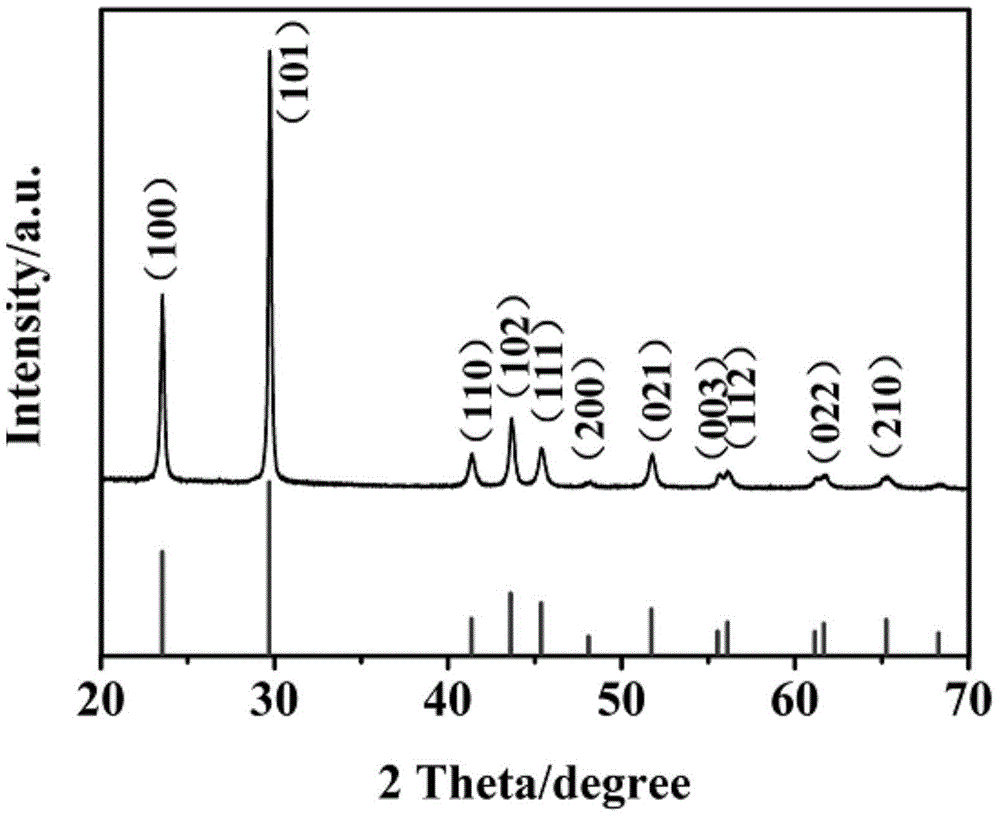

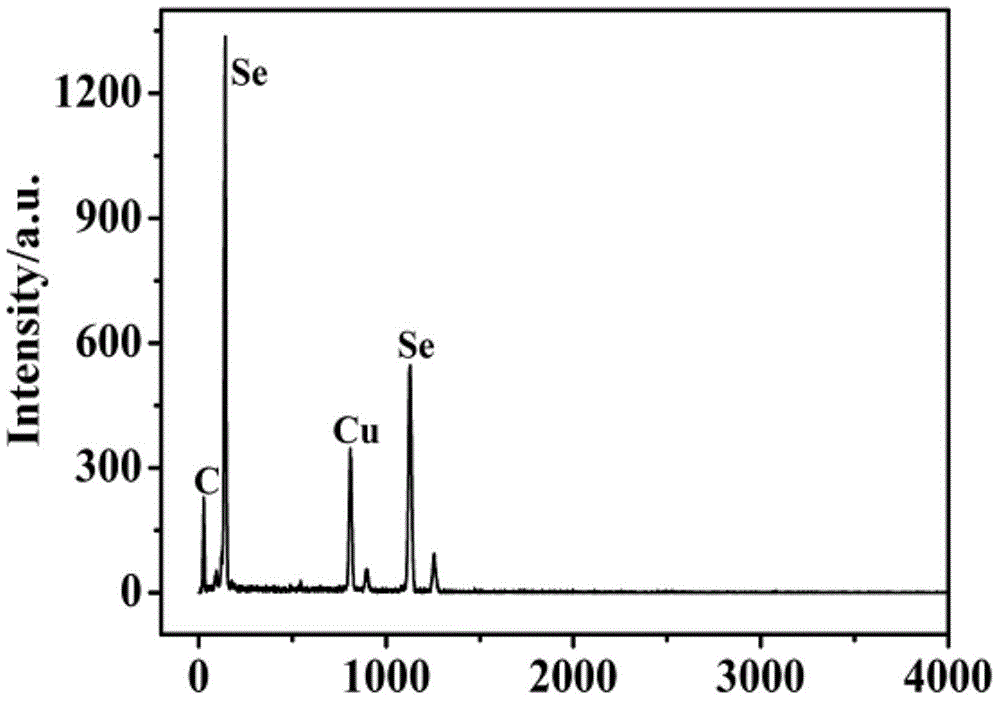

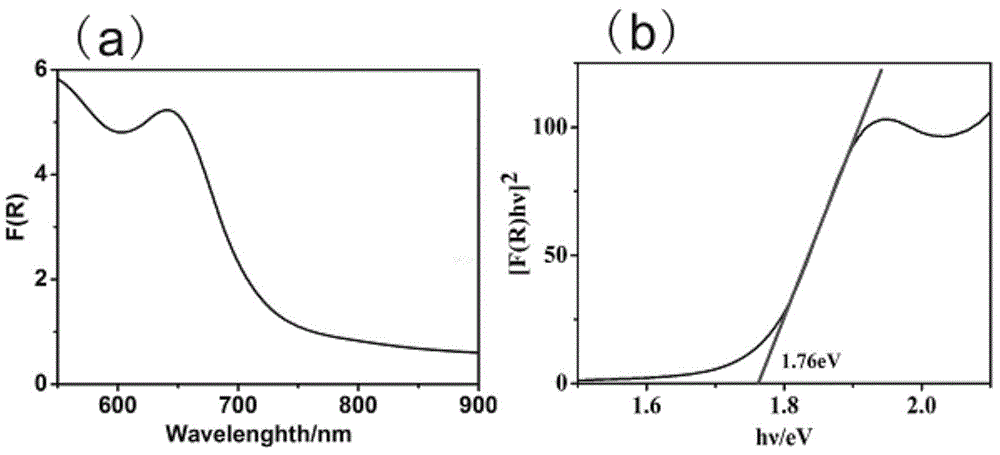

[0029] The phase of the product prepared in this embodiment is tested by X-ray diffraction spectrum (XRD), using Rigaku D / Max-RB instrument Product characterization analysis. The ultraviolet-visible diffuse reflectance spectrum (DRS) was tested with a Lambda 35UV / Vis spectromet...

Embodiment 2

[0037] The method of the single crystal selenium nanorod visible light photocatalytic material t-Se NRs prepared in this example is as follows: (1) Preparation of amorphous α-Se

[0038] Weigh 0.111g SeO 2 , 0.352g of ascorbic acid were dissolved in 8mL of deionized water, after the dissolution was complete, the ascorbic acid solution was slowly added dropwise to the selenous acid solution. sex. Finally, the solid phase product obtained by centrifugation is α-Se.

[0039] (2) Preparation of single crystal gray selenium t-Se NRs

[0040] Then transfer the prepared α-Se to a container with a concentration of 1×10 -5 mol / L NaOH ethanol solution, after static aging for 20 h, the gray product was obtained after washing and drying, which were t-Se NRs. The SEM images of the prepared t-Se NRs are shown in Figure 4 As shown in (2), it is rod-shaped, with a diameter of 200nm and a length of 10-20um.

Embodiment 3

[0042] The method of the single crystal selenium nanorod visible light photocatalytic material t-Se NRs prepared in this example is as follows: (1) Preparation of amorphous α-Se

[0043] Weigh 0.111g SeO 2, 0.352g of ascorbic acid were dissolved in 10mL of deionized water, after the dissolution was complete, the ascorbic acid solution was slowly added dropwise to the selenous acid solution. sex. Finally, the solid phase product obtained by centrifugation is α-Se.

[0044] (2) Preparation of single crystal gray selenium t-Se NRs

[0045] Then transfer the prepared α-Se to a container with a concentration of 1×10 -4 mol / L NaOH ethanol solution, after static aging for 22h, the gray product was obtained after washing and drying, which were t-Se NRs. The SEM images of the prepared t-Se NRs are shown in Figure 4 As shown in (3), it is rod-shaped, with a diameter of 300-400nm and a length of about 5um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com