G-carbon nitride-titanium dioxide-silver nanosheet composite, biomimetic synthesis method and application thereof

A technology of titanium dioxide and silver nanosheets, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as limiting solar energy utilization efficiency, achieve mild conditions, facilitate absorption, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

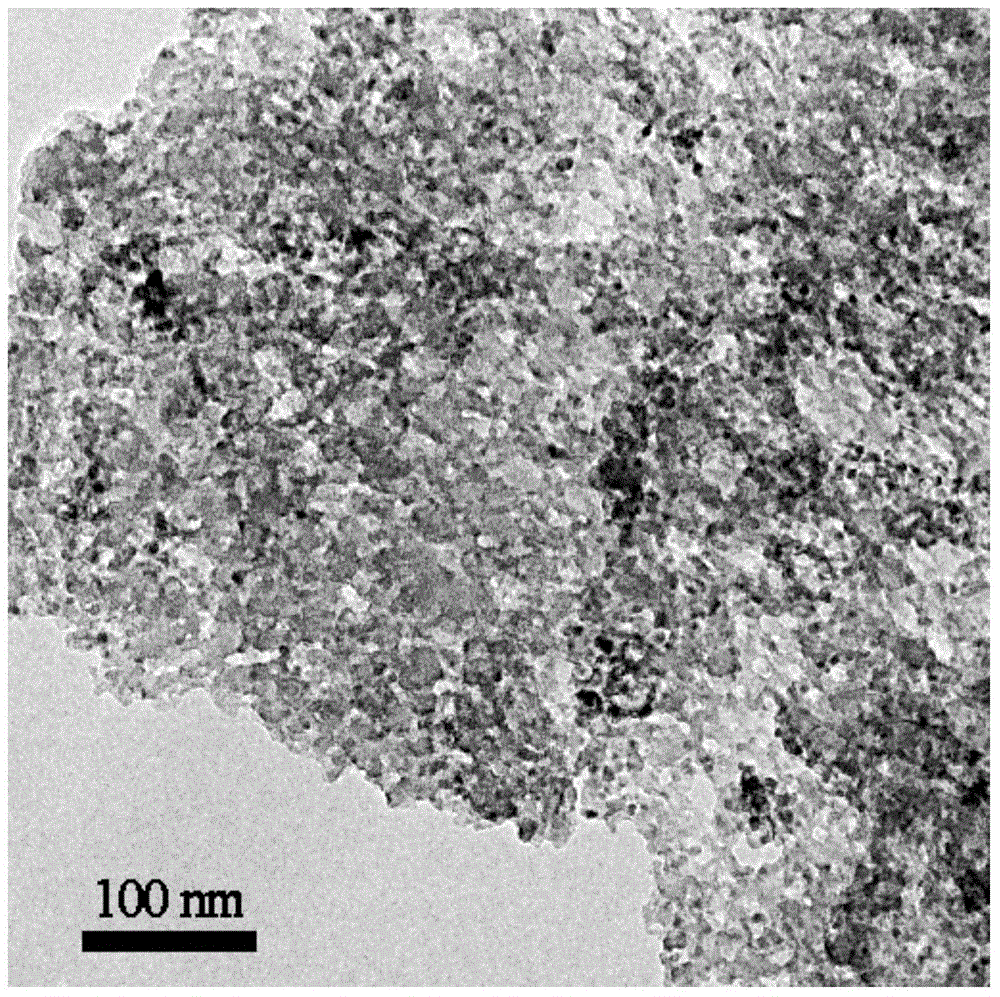

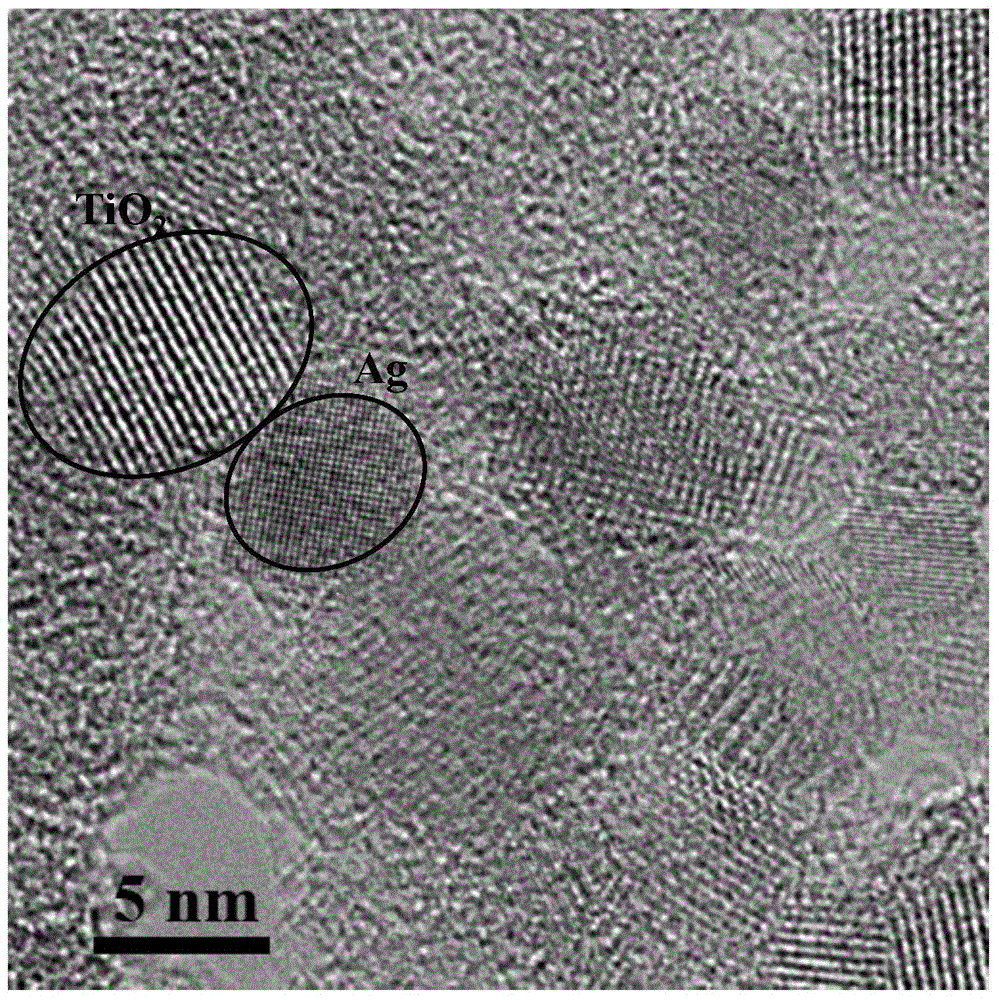

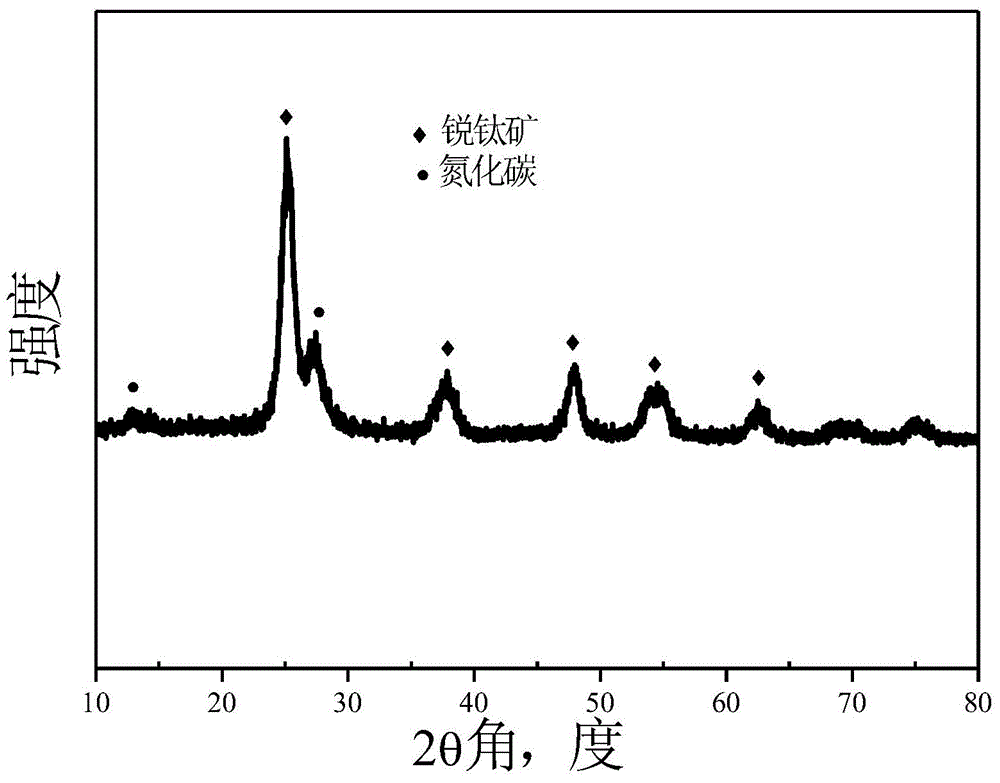

[0021] Embodiment 1: prepare g-carbon nitride-titanium dioxide-silver nanosheet composite, comprising the following steps:

[0022] Step 1) Weigh 10 g of melamine powder, put it in an alumina crucible, and calcinate at 550° C. for 4 hours to obtain carbon nitride.

[0023] Step 2) Weigh 0.104g of arginine, dissolve it in 10mL of deionized water to obtain a 0.6mol / L arginine solution, and adjust the pH of the arginine solution to 7;

[0024] The configuration concentration is 0.25mol / L bis(2-hydroxypropionic acid)diammonium titanium hydroxide (Ti-BALDH) solution;

[0025] Configure a carbon nitride suspension with a concentration of 60mg / mL;

[0026] Step 3) Take 10 mL of arginine solution with a pH of 7, add it to the carbon nitride suspension, and stir for 3 hours. Then add 1ml of 0.25 mol / L Ti-BALDH solution to the above mixture, stir for 0.5h to obtain a carbon nitride-titanium dioxide precipitation complex, dry and calcinate in a muffle furnace at 480°C for 2 hours to ob...

Embodiment 2

[0029] Embodiment 2: prepare g-carbon nitride-titanium dioxide-silver nanosheet composite, comprising the following steps:

[0030] Step 1) prepare carbon nitride, same as Example 1;

[0031] Step 2) configure arginine solution, Ti-BALDH solution and carbon nitride suspension, the same as in Example 1;

[0032] Step 3) prepare sheet g-carbon nitride-titanium dioxide composite, same as Example 1;

[0033] Step 4) Dissolve the flaky g-carbon nitride-titanium dioxide complex prepared above in 10ml of water to prepare a 5mg / ml suspension, add 2ml of 2mg / ml diHPP solution, and stir vigorously for 30min. The resulting solution was centrifuged and washed three times, and 20 ml of AgNO was added 3 solution, making Ag + The concentration was 2mmol / L, and stirred at room temperature for 24h. Washing with deionized water and freeze-drying to obtain the g-carbon nitride-titanium dioxide-silver-2 nanosheet composite.

Embodiment 3

[0034] Embodiment 3: prepare g-carbon nitride-titanium dioxide-silver nanosheet composite, comprising the following steps:

[0035] Step 1) prepare carbon nitride, same as Example 1;

[0036] Step 2) configure arginine solution, Ti-BALDH solution and carbon nitride suspension, the same as in Example 1;

[0037] Step 3) prepare sheet g-carbon nitride-titanium dioxide composite, same as Example 1;

[0038] Step 4) Dissolve the flaky g-carbon nitride-titanium dioxide complex prepared above in 10ml of water to prepare a 5mg / ml suspension, add 2ml of 2mg / ml diHPP solution, and stir vigorously for 30min. The resulting solution was centrifuged and washed three times, and 20 ml of AgNO was added 3 solution, making Ag + The concentration was 1mmol / L, and stirred at room temperature for 24h. Washing with deionized water and freeze-drying to obtain the g-carbon nitride-titanium dioxide-silver-1 nanosheet composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com