Novel crystal form of cefuroxime sodium and preparation method of cefuroxime sodium crystal

A cefuroxime sodium and crystal form technology, applied in the field of chemical engineering crystallization, can solve problems such as short shelf life, poor thermal stability, and increased storage difficulty, achieve moderate pH, avoid yield loss, and reduce the cost of decolorization and filtration processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

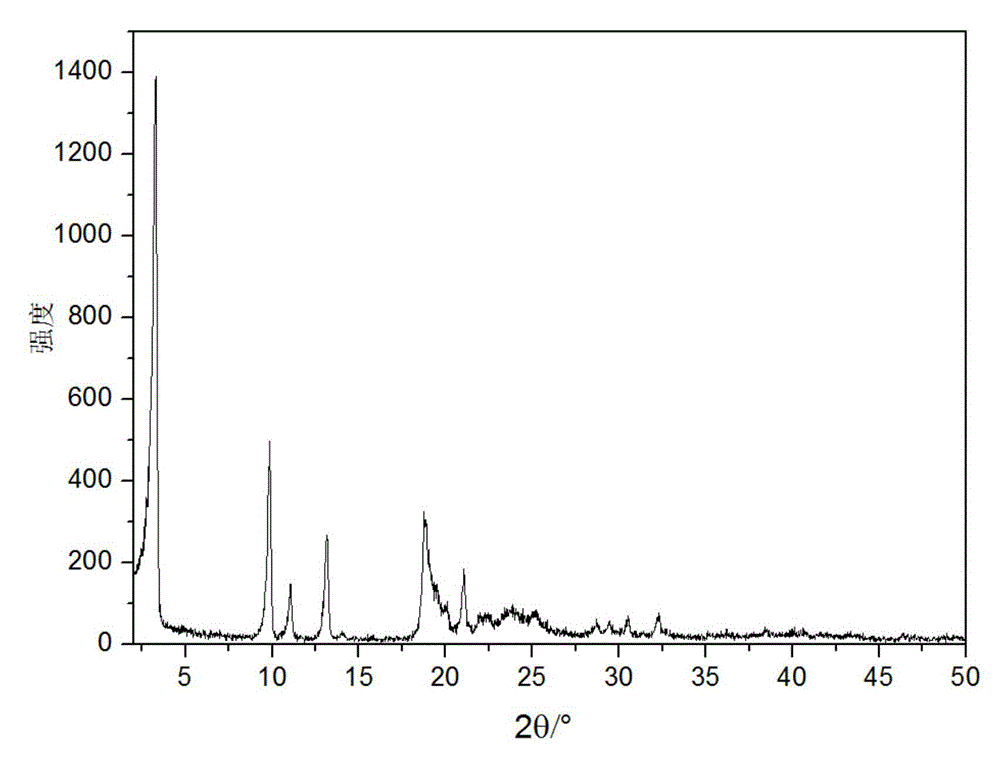

[0024] Add 5 g of cefuroxime acid into the crystallizer, and at the same time add 100 ml of methanol, and stir at 20°C. Then, a sodium lactate-methanol solution with a concentration of 0.3 g / ml was added into the crystallizer for reaction, and the pH value at the end of the reaction process was controlled at 6.0. Then dropwise add 500ml of ethanol eluent at a rate of 2ml / min. After the crystallization was completed, the crystal slurry was filtered, washed with ethanol, and the obtained crystal product was dried at 40° C. and 0.005 MPa for 5 hours. The one-way mass yield of the crystal product is 93.4%, and the purity is 99.54%. Its X-ray powder diffraction has characteristic peaks at diffraction angles 2θ=3.5, 10.6, 12.7, 18.6, 19.6, and 22.4 degrees. Characteristic peaks.

Embodiment 2

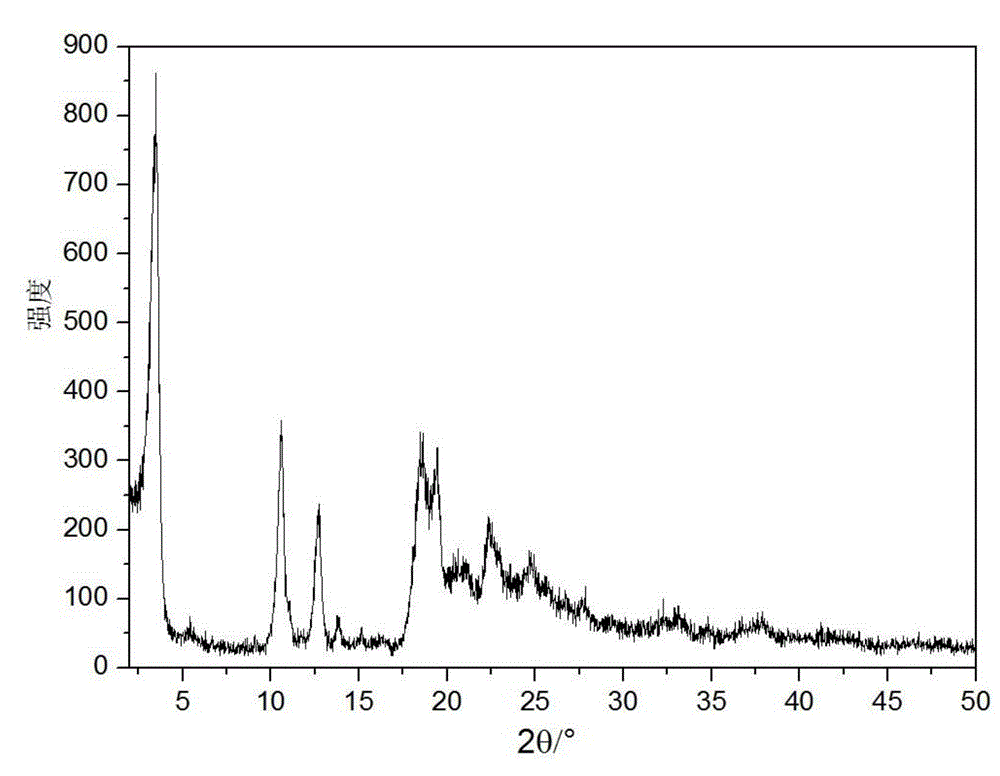

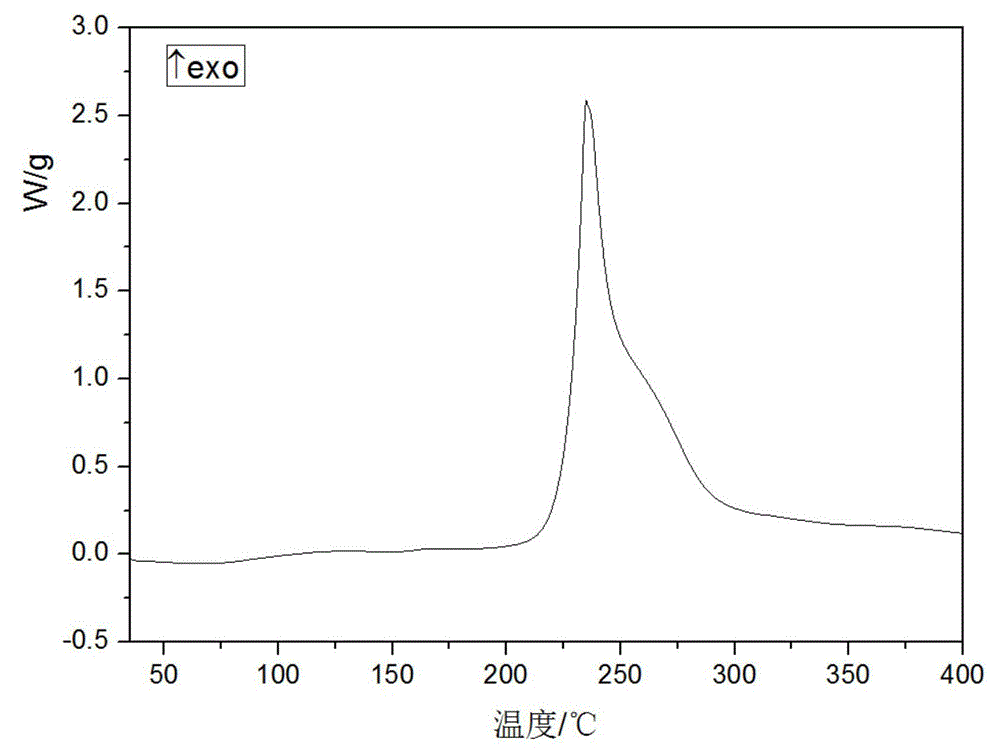

[0026] Add 2.5g of cefuroxime acid into the crystallizer, add 50ml of methanol and 50ml of ethanol at the same time, and stir at 23°C. Then, a sodium lactate-methanol solution with a concentration of 0.2 g / ml was added into the crystallizer for reaction, and the pH value at the end of the reaction process was controlled at 6.2. Then dropwise add 200ml of ethanol eluent at a rate of 0.5ml / min. After the crystallization was completed, the crystal slurry was filtered, washed with ethanol, and the obtained crystal product was dried at 40° C. and 0.01 MPa for 4 hours. The one-way mass yield of the crystal product is 94.7%, and the purity is 99.52%. Its X-ray powder diffraction has characteristic peaks at diffraction angles 2θ=3.4, 10.6, 12.6, 18.6, 19.4, and 22.4 degrees. Its DSC spectrum has Characteristic peaks.

Embodiment 3

[0028] Add 3g of cefuroxime acid into the crystallizer, add 50ml of methanol and 50ml of n-propanol at the same time, and stir at 23°C. Then, a sodium lactate-methanol solution with a concentration of 0.3 g / ml was added into the crystallizer for reaction, and the pH value at the end of the reaction process was controlled at 6.3. Then add 100ml ethanol and 150ml n-propanol eluent dropwise at a rate of 0.8ml / min. After the crystallization was completed, the crystal slurry was filtered, washed with ethanol, and the obtained crystal product was dried at 35° C. and 0.02 MPa for 3 hours. The one-way mass yield of the crystal product is 93.5%, and the purity is 99.59%. Its X-ray powder diffraction has characteristic peaks at diffraction angles 2θ=3.5, 10.8, 12.8, 18.6, 19.7, and 22.4 degrees, and its DSC spectrum has Characteristic peaks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com