Spray-free polypropylene composite material with antibacterial function, preparation method and application

A composite material, spray-free technology, applied in the field of modified plastics, can solve the problems of plastic products prone to mold, difficult to recycle and reuse, and high cost, achieve strong flickering effect and metal texture, low cost, and safer use characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

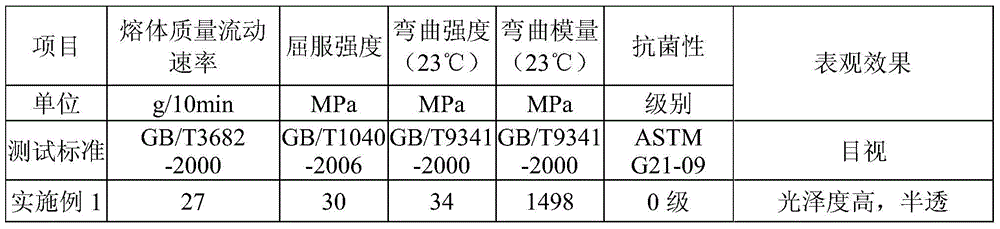

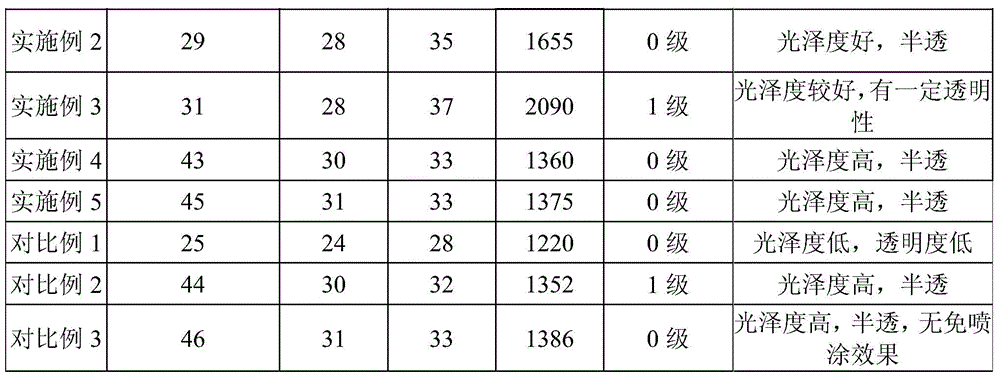

Examples

Embodiment 1

[0043]Proportioning is carried out according to the following mass percentage composition: Homopolypropylene (brand: N-Z30S, melt flow rate is 25g / 10min, test condition: 230°C / 2.16KG, China Petrochemical Corporation Maoming Branch) 79.5% , transparent filler (anhydrous transparent powder (fine silicon dioxide, average particle size Dv50 is 2.3 μm), Shenzhen Jinhaohui Mining Industry Development Co., Ltd.) 10%, antibacterial agent masterbatch 10%, glass-based pearlescent pigment (model: PLATALUX E, silver-coated pearlescent pigments, Germany Aika Special Effect Pigments (Zhuhai) Co., Ltd.) 0.1%, antioxidant (model: 1010, Lianlong (Tianjin) Chemical Co., Ltd.) 0.1%, antioxidant (model: 168, Lianlong (Tianjin) Chemical Co., Ltd.) 0.1%, lubricant (calcium stearate BS-3818, Zhongshan Huamingtai Chemical Co., Ltd.) 0.2%.

[0044] Wherein, the preparation method of the antimicrobial agent masterbatch described in the present embodiment: carry out proportioning according to the follow...

Embodiment 2

[0048] Proportioning according to the following mass percentage composition: Homopolypropylene (brand: N-Z30S, China Petroleum & Chemical Corporation Maoming Branch) 74%, transparent filler (anhydrous transparent powder, Shenzhen Jinhaohui Mining Development Co., Ltd. ) 20%, antibacterial agent masterbatch (obtained by the preparation method of Example 1) 5%, glass-based pearlescent pigment (model: PLATALUX E, Germany Aika Special Effect Pigment (Zhuhai) Co., Ltd.) 0.5%, antioxidant (model : 1010, Lianlong (Tianjin) Chemical Co., Ltd.) is 0.1%, antioxidant (model: 168, Lianlong (Tianjin) Chemical Co., Ltd.) is 0.2%, lubricant (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Ltd.) 0.2%.

[0049] After weighing the above-mentioned materials, add them into a high-speed mixer (rotating speed 1000rpm) and stir for 10 minutes. Put the uniformly stirred material into the main feeding hopper of the parallel twin-screw extruder, and set the temperature of each section of the...

Embodiment 3

[0052] Proportioning according to the following mass percentage composition: Homopolypropylene (brand: N-Z30S, China Petroleum & Chemical Corporation Maoming Branch) 66.5%, transparent filler (anhydrous transparent powder, Shenzhen Jinhaohui Mining Development Co., Ltd. ) 30%, antimicrobial agent masterbatch 2%, glass-based pearlescent pigment (model: PLATALUX E, Germany Erka Special Effect Pigment (Zhuhai) Co., Ltd.) 1%, antioxidant (model: 1010, Lianlong (Tianjin) Chemical Co., Ltd.) was 0.1%, the antioxidant (model: 168, Lianlong (Tianjin) Chemical Co., Ltd.) was 0.1%, and the lubricant (calcium stearate 3818, Zhongshan Huamingtai Chemical Co., Ltd.) was 0.3%.

[0053] Wherein, the preparation method of antimicrobial agent masterbatch described in the present embodiment: carry out proportioning according to following mass percentage composition: Homopolypropylene N-Z30S is 59.7%, antibacterial agent IONPURE IPL (Ishizuka Glass Co., Ltd. of Japan) is 40% , antioxidant 1010 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com