Vanadium nitride (VN) porous hollow nano-fiber and preparation method thereof

A hollow nano, vanadium nitride technology, used in fiber processing, fiber chemical characteristics, spinning solution preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

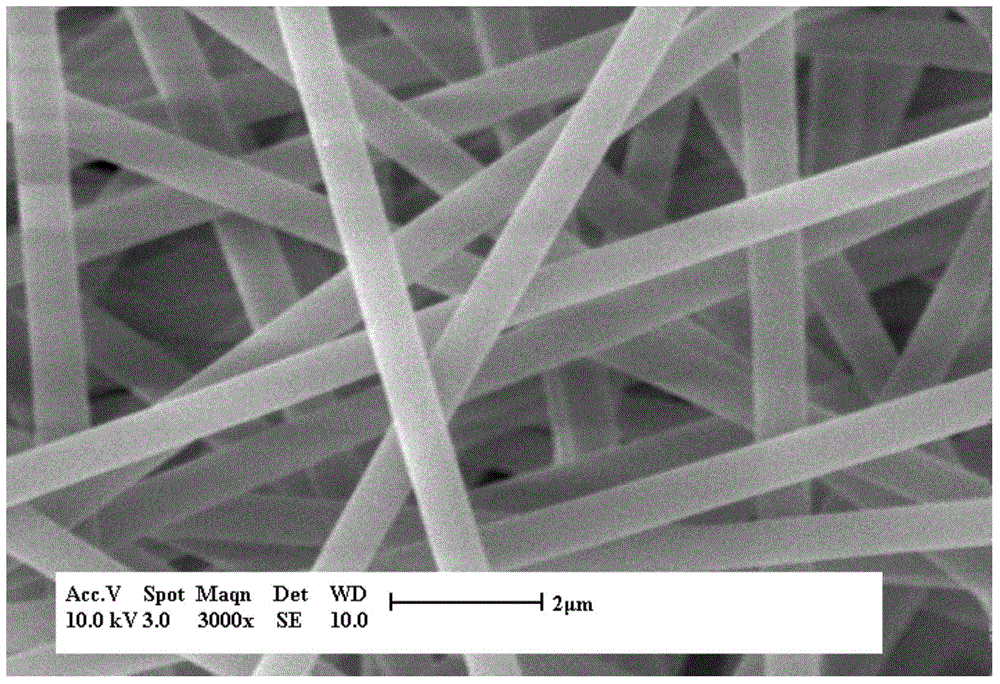

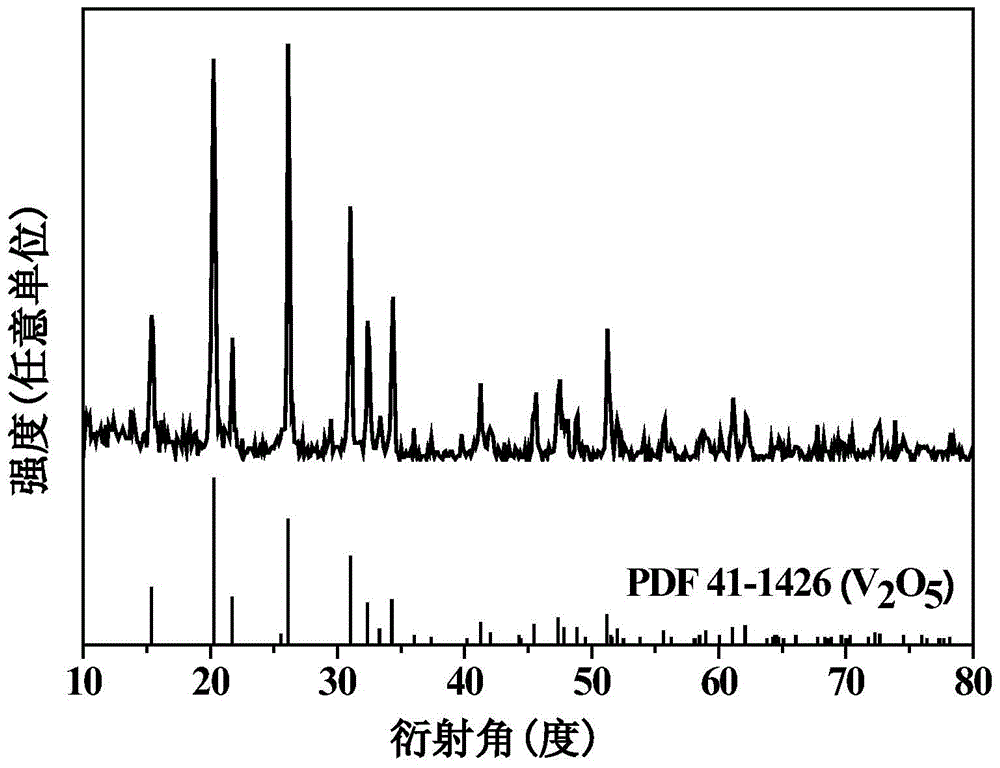

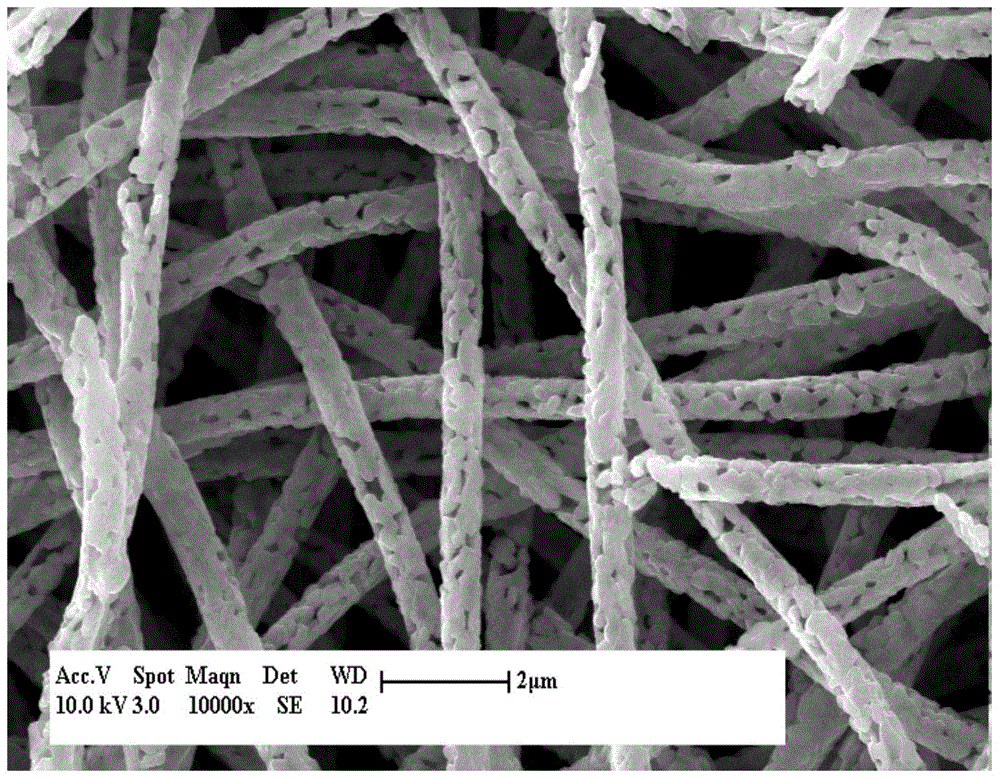

[0024] Embodiment: 2.0124g ammonium metavanadate NH 4 VO 3 with 7.1850g citric acid C 6 h 8 o 7 ·H 2 Dissolve O in an appropriate amount of deionized water, heat and stir until the solid powder is completely dissolved and then evaporate to form a gel. After cooling to room temperature, add 16.0360g N,N-dimethylformamide DMF and 2.0512g polyvinylpyrrolidone PVP, and stir for 12 hours Obtain a uniformly dispersed spinning solution; inject the spinning solution into a 10mL syringe with a 1mL plastic spray gun head, insert a graphite rod into the spinning solution as an anode, the angle between the spinneret and the horizontal plane is 30°, and spray The distance between the wire head and the receiving screen wire mesh is 18cm, the spinning voltage is 13kV, the indoor temperature is 24°C, and the relative humidity is 30%-40%. With the volatilization of the solvent, PVP / C can be obtained on the receiving screen wire mesh 6 h 8 o 7 / NH 4 VO 3 Composite nanofibers; the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com