Terahertz microbolometer based on metamaterial absorber and preparation method of terahertz microbolometer

A microbolometer and metamaterial technology, applied in the field of uncooled terahertz detection, can solve the problems of limited structure size, low terahertz absorption rate, and harsh preparation conditions for terahertz absorption films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

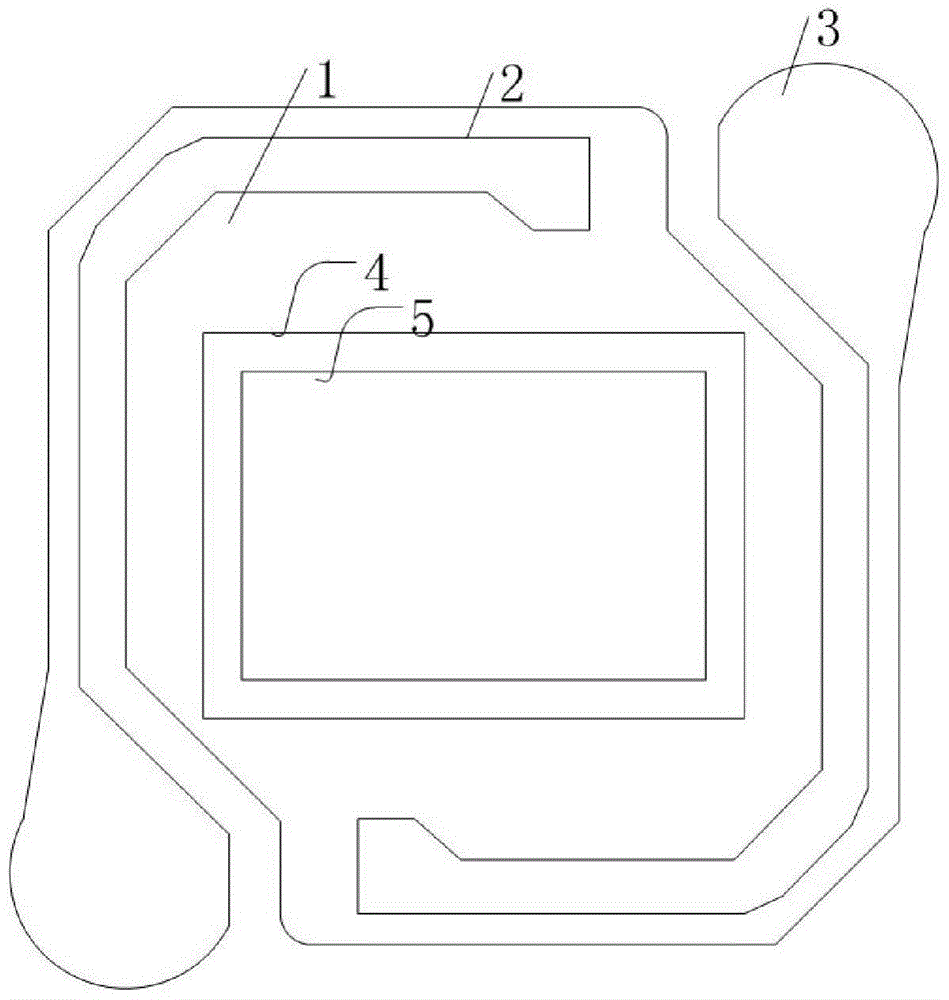

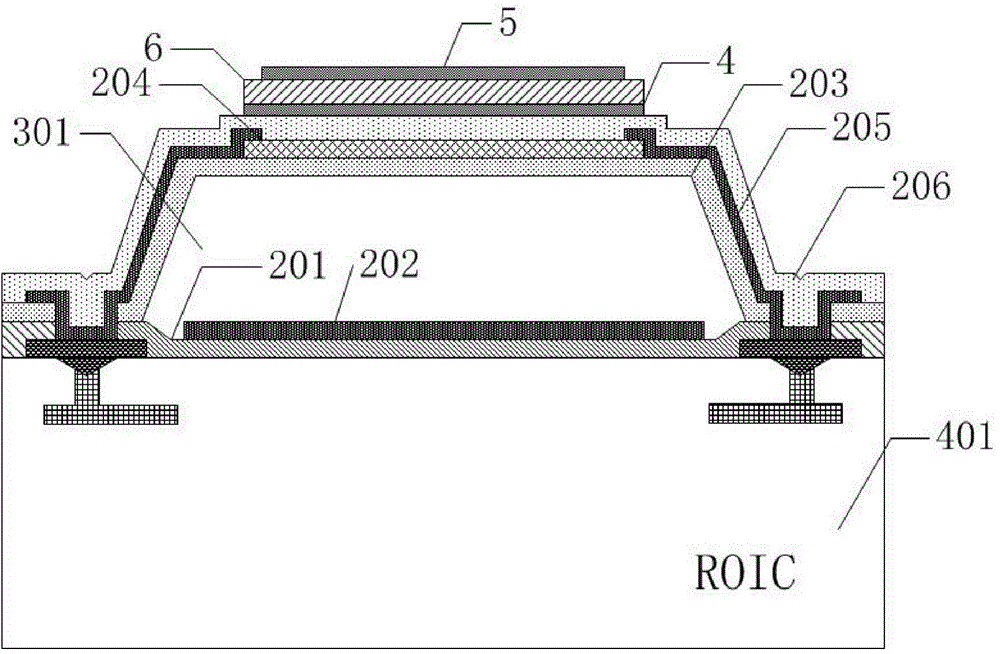

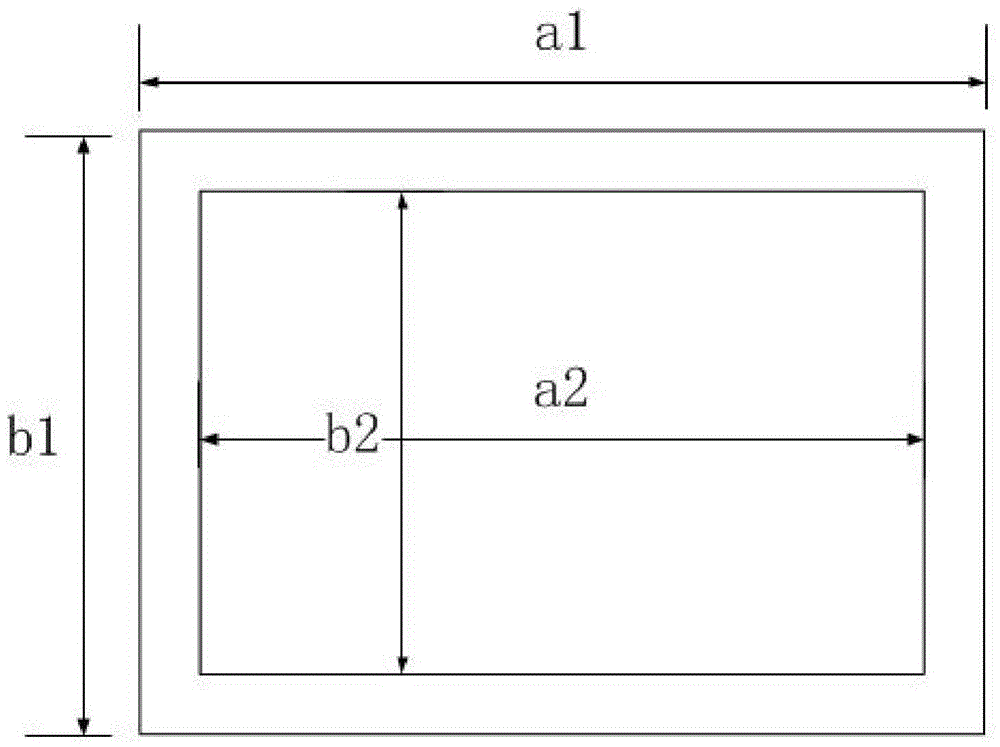

[0045] Such as figure 1 and figure 2 As shown, the metamaterial-based terahertz microbolometer is composed of two parts: a metamaterial terahertz absorber and a thermal detector, wherein the thermal detector includes the bottom microbridge support layer 203, the second thermal sensor The resistance film layer 204, the metal electrode layer 205 of the third layer and the passivation layer 206 of the fourth layer; the metamaterial terahertz absorber includes a bottom metal film layer 4, an intermediate dielectric layer 6, and a top metal film layer 5; The underlying metal film 4 of the Hertz absorber is in contact with the passivation layer 206 of the thermal detector. By changing the structural shape and metal conductivity of the metamaterial, as well as the thickness and dielectric constant of the intermediate dielectric layer 6, etc., the response frequency, frequency band and absorption rate of the terahertz wave can be adjusted, so as to obtain a high terahertz wave in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com