A kind of high-performance binder for lithium ion battery silicon material and preparation method thereof

A lithium-ion battery and binder technology, applied in battery electrodes, circuits, electrical components, etc., to achieve excellent electrochemical performance, improve microscopic composition, and reduce internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare a kind of binder for lithium ion battery silicon material of the present invention, preparation method is as follows:

[0038] With a mechanical stirrer, N 2Add monobutyl itaconate (accounting for 5% of monomer mass), azoisobutyronitrile (accounting for 0.5% of monomer mass), n-butyl acrylate in different proportions to the 250mL four-necked flask with protective device and thermometer (accounting for 2% of the mass of acrylonitrile monomer), emulsifier OP10 (accounting for 0.5% of the mass of the monomer), acrylonitrile monomer and water (9 times the mass of the monomer), heated to 110 ° C, and took it out after 24 hours of reaction , after washing and filtering with deionized water several times, the polymer powder whose main component is polyacrylonitrile is obtained, which is used as the binder I for silicon materials of lithium-ion batteries, and its molecular weight is about 280,000.

Embodiment 2

[0040] Prepare a kind of binder for lithium ion battery silicon material of the present invention, preparation method is as follows:

[0041] With a mechanical stirrer, N 2 Add monobutyl itaconate (accounting for 8% of the monomer mass), azoisobutyronitrile (accounting for 0.5% of the monomer mass), n-butyl acrylate in different proportions in the 250mL four-necked flask with protective device and thermometer (2% of monomer mass), emulsifier OP10 (0.5% of monomer mass), acrylonitrile monomer (90% of monomer mass) and water (9 times of monomer mass), heated to Take it out after reacting for 24 hours at 85°C, wash and filter for many times to obtain a polymer powder whose main component is polyacrylonitrile, which is used as the binder II for silicon material of lithium ion battery, and its molecular weight is about 354,000.

Embodiment 3

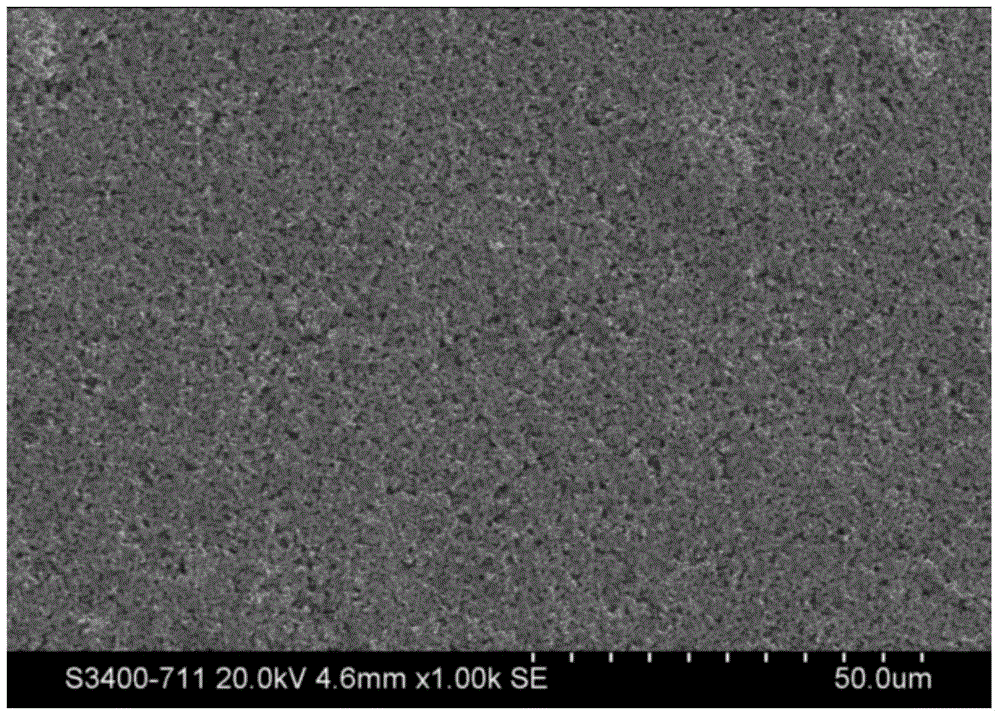

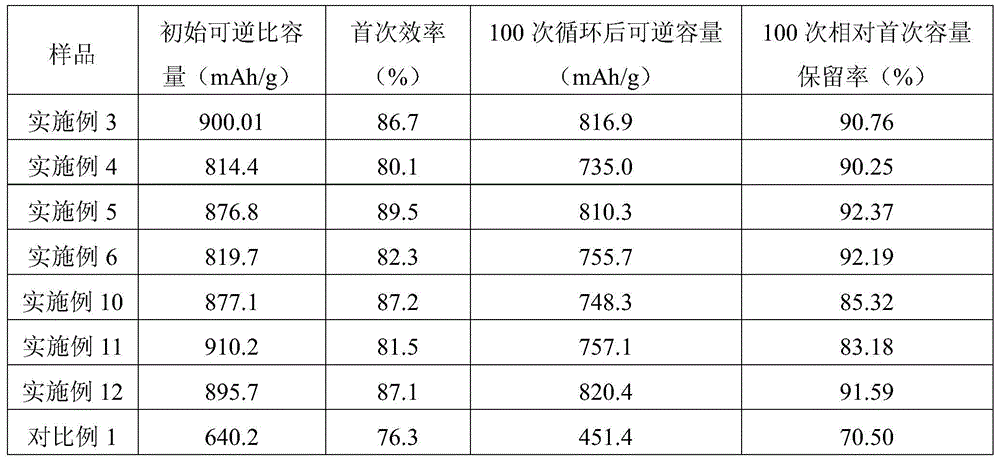

[0043] In this embodiment, a high-purity crystalline silicon (Wt%=99.9%) material with a diameter of ~100 nm and a particle size of ~1 μm Super P, 3 μm mesophase carbon microspheres and MWCNTs are selected as the conductive agent (Super P: MCMB: MWCNTs w / w =60:35:5), using the binder I prepared in Example 1 as the binder material for preparing electrodes.

[0044] Follow the steps below to prepare high-purity crystalline silicon electrodes:

[0045] 1) Weighing 50% of the silicon-based active material and 20% of the carbon material conductive agent according to mass percentage and mixing and dispersing evenly;

[0046] 2) By mass percentage, take 30% of the binder I prepared in Example 1 as binder powder, dissolve it in an appropriate amount of NMP, disperse evenly, and stir into a transparent sol;

[0047] 3) Add the powder obtained in step 1) to the sol-like material obtained in step 2), control the solid content at 40%, stir vigorously, and form a slurry after stirring eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com