A kind of preparation method of the air electrode of aluminum-air battery

An aluminum-air battery and air electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems affecting the performance and service life of air electrodes, insufficient adhesion, leakage, etc., and achieve the distribution of manganese dioxide and carbon Uniformity, good adhesion, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

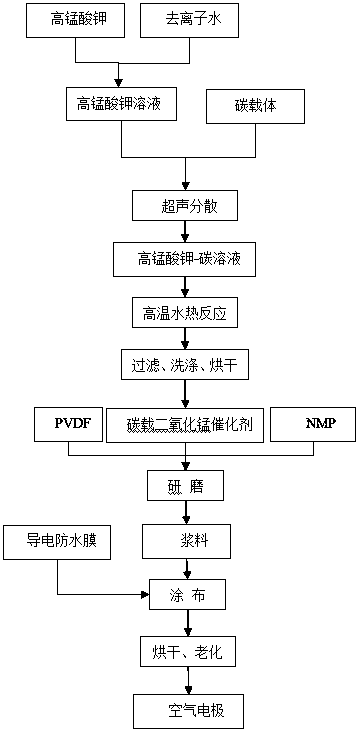

[0047] A method for preparing an air electrode of an aluminum-air battery, comprising the steps of:

[0048] Step (1), 50g potassium permanganate is dissolved in 1000mL deionized water and is mixed with the potassium permanganate solution of concentration 50g / L;

[0049] Step (2), add 2.85g nanometer acetylene black as carbon carrier in the potassium permanganate solution that step (1) makes according to the amount of the substance ratio of potassium permanganate and carbon carrier 1:1, under ultrasonic condition Stir and disperse for 10 minutes to obtain a uniformly dispersed potassium permanganate-carbon solution; the ultrasonic intensity is 50W / cm 2 ; The stirring speed is 200r / min;

[0050] In step (3), the potassium permanganate-carbon solution obtained in step (2) is added in a stainless steel autoclave, and a high-temperature hydrothermal reaction is carried out at 150° C. and a pressure of 0.5 MPa. After the reaction is completed, filter, and the filter residue is was...

Embodiment 2

[0056] A method for preparing an air electrode of an aluminum-air battery, comprising the steps of:

[0057] Step (1), 50g potassium permanganate is dissolved in 2500mL deionized water and is mixed with the potassium permanganate solution of concentration 20g / L;

[0058] Step (2), add 5.7g of activated carbon as carbon carrier to the potassium permanganate solution prepared in step (1) according to the amount of substance ratio of potassium permanganate and carbon carrier of 1:2, and stir under ultrasonic conditions Disperse for 45min to obtain a uniformly dispersed potassium permanganate-carbon solution; the ultrasonic intensity is 90W / cm 2 ; The stirring speed is 1000r / min;

[0059] In step (3), the potassium permanganate-carbon solution obtained in step (2) is added into a stainless steel autoclave, and a high-temperature hydrothermal reaction is carried out at 120°C and a pressure of 0.2MPa. After drying at ℃ for 10 hours, carbon-supported manganese dioxide catalyst powd...

Embodiment 3

[0065] A method for preparing an air electrode of an aluminum-air battery, comprising the steps of:

[0066] Step (1), 50g potassium permanganate is dissolved in 1000mL deionized water and is mixed with the potassium permanganate solution of concentration 25g / L;

[0067] Step (2), add 14.25g graphene to the potassium permanganate solution prepared in step (1) as carbon carrier according to the amount of substance ratio of potassium permanganate and carbon carrier of 1:5, under ultrasonic condition Stir and disperse for 60 minutes to obtain a uniformly dispersed potassium permanganate-carbon solution; the ultrasonic intensity is 70W / cm 2 ; The stirring speed is 600r / min;

[0068] In step (3), the potassium permanganate-carbon solution obtained in step (2) is added into a stainless steel autoclave, and a high-temperature hydrothermal reaction is carried out at 200°C and a pressure of 2.0MPa. After drying at ℃ for 6 hours, carbon-supported manganese dioxide catalyst powder is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com