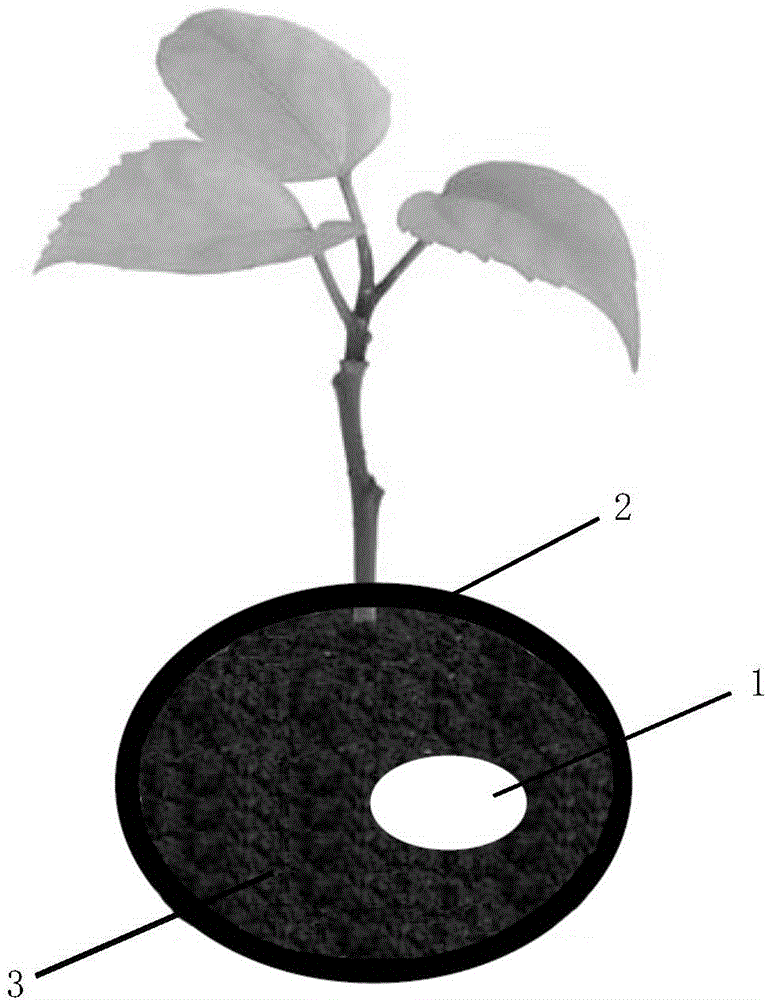

Protective box for protecting growth of plant seedlings

A protection box and plant technology, applied in the field of protection boxes for plant seedling growth, can solve the problems of difficulty in becoming a reality, lack, and high cost of cultivated land, and achieve the effect of maintaining sustainable development, ensuring sustainable utilization, and ensuring thriving growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Polylactic acid is selected as the raw material, and under the action of the injection molding machine, it is injected into a five-sided solid box with a thickness of 20±4mm and a tensile strength of 65±5MPa, and one side is reserved for the position of the optional separation window.

[0078] Cellulose acetate was dissolved in a mixed solution of 1,4-dioxane, lactic acid, methanol and acetone, and stirred at 60° C. for 9 hours to form a casting solution with a concentration of 14 wt%. Coating the casting solution on a 180-mesh nylon screen and drying to obtain a forward osmosis membrane containing the support layer and a polymer membrane layer, with a thickness of 200±20 μm, a water flux of 20LMH, and a salt cut-off rate of >90%.

[0079] Place the forward osmosis membrane at the position of the selective separation window in the state of 80-92wt% dehydration, and then use a hot press to heat press the forward osmosis membrane into the box. The hot-pressing temperature ...

Embodiment 2

[0085] Choose cornstarch as the raw material, and inject it into a five-sided solid box under the action of the injection molding machine, with a thickness of 10±5mm and a tensile strength of 45±5MPa, with a position for the optional separation window on one side.

[0086] Cellulose triacetate was dissolved in a mixed solution of 1,4-dioxane, lactic acid, methanol and acetone, and stirred at 65°C for 9 hours to form a casting solution with a concentration of 15wt%. Coating the casting solution on a 200-mesh polyester non-woven fabric and drying to obtain a forward osmosis membrane containing the support layer and a polymer film layer, with a thickness of 150±20 μm, a water flux of 15LMH, and a salt cut-off rate of >90%.

[0087] Place the forward osmosis membrane at the position of the selective separation window under the state of 88-90wt% dehydration, and then use a hot press to heat press the forward osmosis membrane into the box. The hot pressing temperature is 220-240 °C, ...

Embodiment 3

[0092] Choose cellulose as the raw material, and inject it into a five-sided solid box under the action of the injection molding machine, with a thickness of 15±5mm and a tensile strength of 55±5MPa, with a position for selecting a separation window on one side.

[0093] Polysulfone was dissolved in N-methylpyrrolidone and stirred at 60°C for 12 hours to form a casting solution with a concentration of 15wt%. The casting solution is coated on a 200-mesh polyester non-woven fabric to obtain an ultrafiltration base membrane. After drying or drying the basement film, soak it in the prepared 2% m-phenylenediamine aqueous solution for 8 minutes, take it out, dry it in the shade, soak it in the prepared n-hexane solution of 0.1% trimesoyl chloride for 90 seconds, and then soak it in the 100 Heat treatment at ℃ for 7 minutes to obtain a composite forward osmosis membrane with a thickness of 150±20 μm, a water flux of 15LMH, and a salt cut-off rate of >90%.

[0094] Place the forward ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com