An absorbent for reducing methane concentration

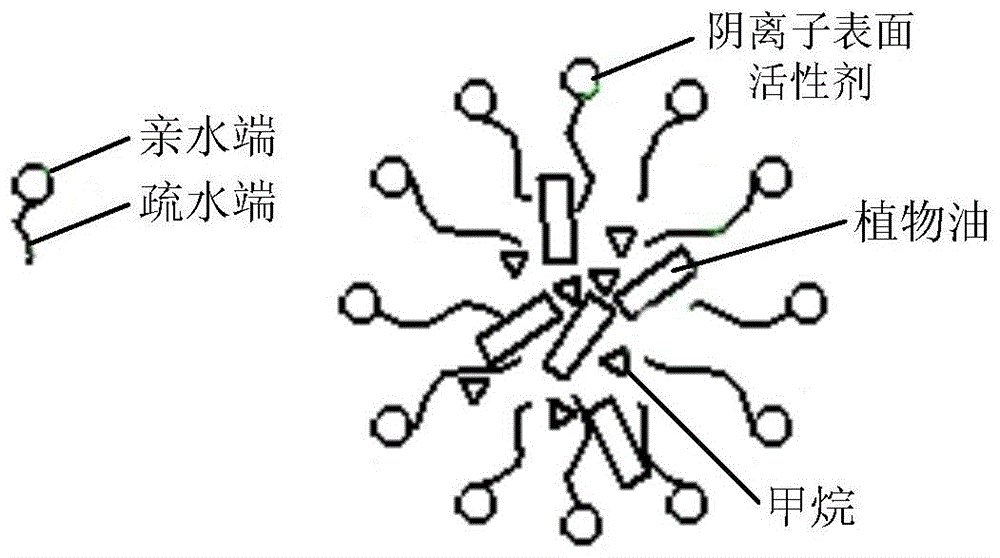

A methane concentration and absorbent technology, which is applied in the field of absorbents for reducing methane concentration, can solve the problems of single surfactant, low gas absorption effect, and difficulty in reducing gas concentration, so as to enhance safety, reduce gas concentration, increase The effect of large particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Sodium dodecyl sulfate (SDS), sodium dodecylbenzenesulfonate (SDBS), sodium oleate, fatty alcohol polyoxyethylene ether carboxylate (AEC), lauryl ether phosphate The five single surfactants of potassium (MAEPK) were subjected to methane absorption experiments, and the volume fractions of methane absorbed when the solute mass fractions of the surfactants were 5%, 10%, 15%, and 20% were respectively measured. The specific experimental results of this example 1 can be shown in the following table 1:

[0030] Table 1:

[0031] Solute mass fraction of surfactant 5% 10% 15% 20% Volume fraction of methane absorbed by SDS 4.48% 5.21% 5.74% 6.24% Volume fraction of methane absorbed by SDBS 3.65% 4.49% none none Volume fraction of methane absorbed by sodium oleate 5.35% 5.87% 5.76% none Volume fraction of methane absorbed by AEC 4.12% 4.62% 5.45% 5.86% Volume fraction of methane absorbed by MAEPK 3.78% 4.02% 4.43% 4.98...

example 2

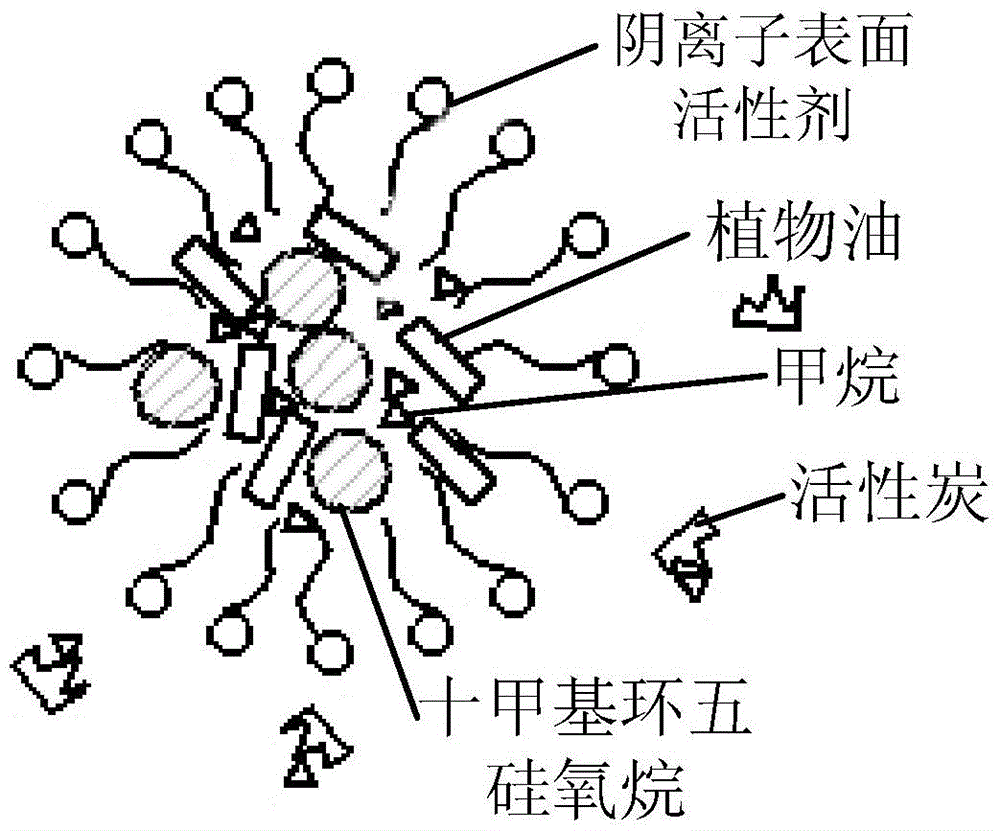

[0033] Adopt sodium dodecyl sulfate (SDS) to carry out compounding respectively with these 4 kinds of vegetable oils of castor oil, olive oil, cottonseed oil, peppermint oil, and measure the mass ratio of SDS and every kind of vegetable oil respectively at 6:1, 8: 1. Volume fraction of methane absorbed at 9:1, 11:1, 13:1, 17:1, 19:1; SDS, castor oil and decamethylcyclopentasiloxane were used to compound and measure Get the volume fraction of absorbed methane when the mass ratio of SDS and castor oil is respectively at 6:1, 8:1, 9:1, 11:1, 13:1, 17:1, 19:1, wherein decamethyl The consumption of cyclopentasiloxane accounts for 4% of the mass sum of the three. The specific experimental results of this example 2 can be shown in the following table 2;

[0034] Table 2:

[0035]

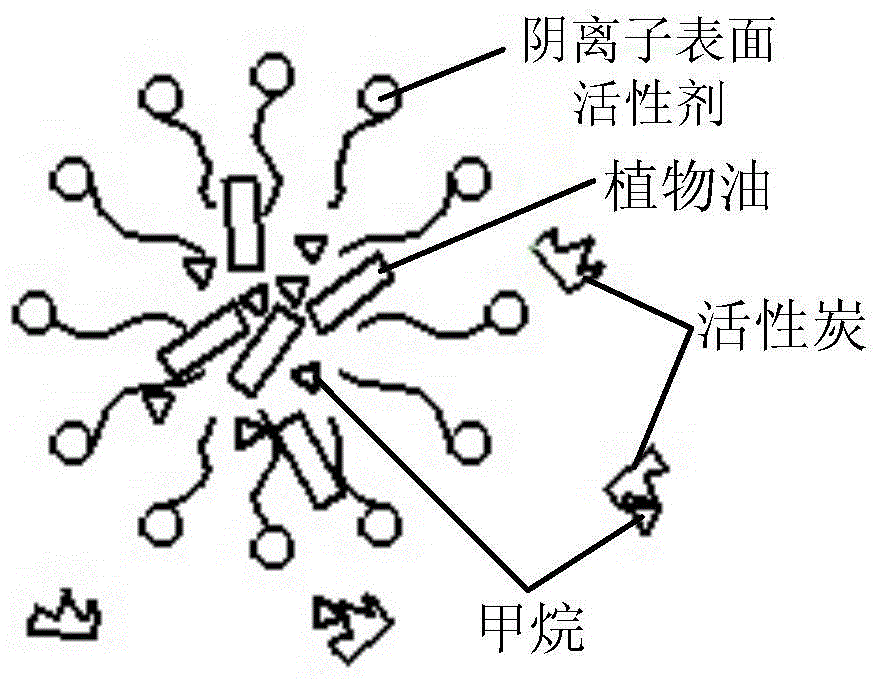

[0036]By comparing the measurement results of example 1 and example 2, it can be seen that: compared with a single surfactant, the absorbing agent compounded by SDS and vegetable oil has improved the ...

example 3

[0039] Adopt sodium dodecyl sulfate (SDS) to carry out compounding respectively with these 4 kinds of vegetable oils of castor oil, olive oil, cottonseed oil, peppermint oil, and measure the mass ratio of SDS and every kind of vegetable oil respectively at 6:1, 13: 1. The volume fraction of methane absorbed at 19:1. At the same time, SDS, castor oil and activated carbon were used to compound, and the volume fractions of methane absorbed when the mass ratios of SDS and castor oil were 6:1, 13:1, and 19:1 were measured, and the amount of activated carbon accounted for three 0.03% of the total mass of those. Then use SDS, castor oil, decamethylcyclopentasiloxane and activated carbon to compound, and measure the volume of methane absorbed when the mass ratio of SDS and castor oil is 6:1, 13:1, 19:1 Fractions, wherein the amount of decamethylcyclopentasiloxane accounts for 4% of the total mass of the three, and the amount of activated carbon accounts for 0.03% of the total mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com