Hydrogenation catalyst as well as preparation method and application thereof

A catalyst and hydrofining technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as product quality not meeting requirements, achieve increased dispersion, improve product quality, and improve operation Effects of Stability Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Roast kaolin raw soil in a high-temperature furnace at a temperature of 600°C and keep the temperature for 4 hours. After cooling, weigh 30g and put it into a container, add 150mL of 2mol / L nitric acid and 150mL of 2mol / L citric acid, and heat for reaction. The reaction temperature is 60°C, and the reaction time is 8h.

[0025] (2) Add 30g of Y-type molecular sieve to the modified kaolin slurry, then add 700mL of distilled water, the solid content in the slurry is 6wt%, and heat to 70°C. The prepared concentration is 46gAl 2 o 3 / L of sodium metaaluminate and a concentration of 15gAl 2 o 3 / L of aluminum sulfate solution was added to the modified kaolin slurry in parallel, and the pH was controlled to be 8.5, and the temperature was maintained at 70°C during the gelation process. Add 40mL of the condensation product of alkylphenol and propylene oxide (OP-10), an organic pore-enlarging agent, after gel formation. The aging time was 40 minutes, and the aged slurry...

Embodiment 2

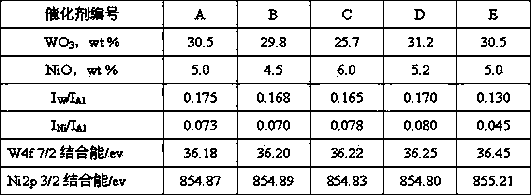

[0029] Other conditions are the same as in Example 1, except that the amount of the mixture of ethyl acetoacetate and acetic acid is changed to 80 g (including 20 g of ethyl acetoacetate and 60 g of acetic acid). The finished product number of the catalyst is B, and the properties of the catalyst are shown in Table 1. Example 3

Embodiment 3

[0030] Other conditions are with embodiment 1, just replace ethyl acetoacetate with butyl acetoacetate, replace acetic acid with succinic acid. The finished product number of the catalyst is C, and the properties of the catalyst are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com