Preparation method of MgO-modified silicoaluminophosphate fluidized bed catalyst

A silicoaluminophosphate fluidized bed and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low ethylene selectivity, achieve high yield, avoid channel blockage, prevent The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare 0.8 M magnesium acetate and 0.6 M oxalic acid solution, under continuous stirring, add the magnesium acetate solution to the oxalic acid solution according to the equivalent ratio, stir and age the solution for 12 hours, filter and dry at 110 °C to obtain magnesium oxalate .

[0021] The magnesium oxalate was calcined at 520°C for 4 hours to obtain a specific surface area of 420 m 2 / g of MgO.

[0022]

example 15

[0024]According to the proportion 15% (weight) SAPO-34 molecular sieve; 2% (weight) magnesium oxalate; 1% (weight) LAS; 17% (weight) kaolin; 7% (weight) aluminum sol; 58% (weight) deionized water Weigh the raw materials. Except for water, the proportions of raw materials in the proportioning here are dry basis weight ratios. Mix SAPO-34 molecular sieve with a certain amount of water, stir for 1 hour, stir thoroughly, and form a uniform molecular sieve suspension after high-speed shearing with a high-speed shear for 15 minutes; add aluminum sol to the suspension, and stir rapidly for 15 minutes. Minutes, use a high-speed shearing machine to cut for 15 minutes; add kaolin and magnesium oxalate, stir for 30 minutes, after reaching a uniform state, use a high-speed shearing machine for high-speed shearing and mixing for 45 minutes to obtain a suspension before spray drying. The particle size of the suspension was measured with a laser particle size analyzer, and the average parti...

Embodiment 3~8

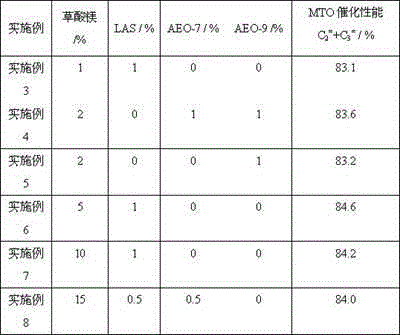

[0027] The operation steps and experimental conditions are the same as in Example 2, wherein the additions of molecular sieve, kaolin and aluminum sol are unchanged, and the additions of magnesium oxalate and surfactant are changed. The MTO catalytic results of the obtained samples are shown in Table 1.

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com