Sand core of pipe mould

A technology of sand cores and sand cores, which is applied in the direction of cores, molds, mold components, etc., can solve the problems of poor collapsibility, insufficient processing, and easy deformation of the inner circle, so as to improve the structure and performance, improve work efficiency, and improve collapsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

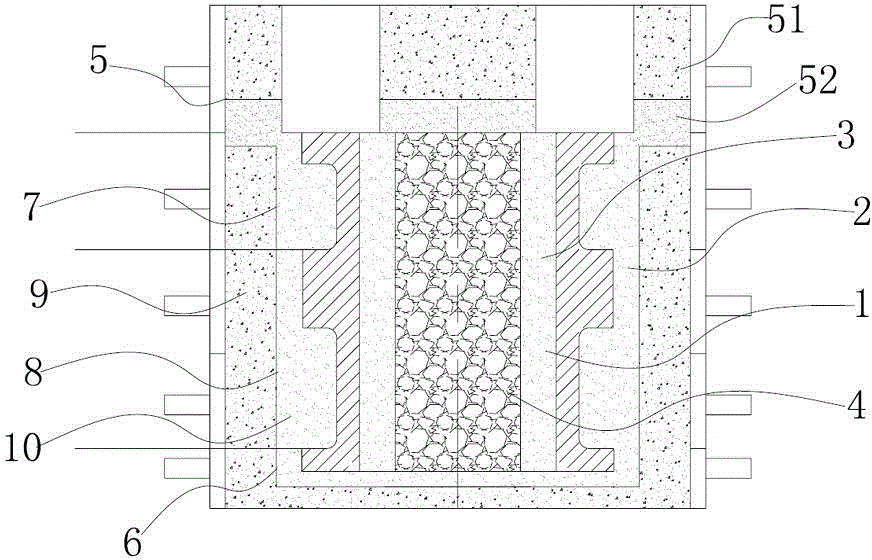

[0020] Embodiment 1: as figure 1 As shown, the pipe mold sand core includes an inner sand core 1 and an outer sand mold 2, and a mold cavity is formed between the sand core 1 and the sand mold 2. The sand core 1 includes a water glass sand core outer wall 3 of a cylindrical structure and is filled in water glass The sand block and sawdust 4 in the cavity surrounded by the outer wall of the sand core, and the outer wall 3 of the sodium silicate sand core are integrated; the sand mold is composed of four sand mold monomers stacked, and the four sand mold monomers include the riser section 5 at the upper end , the bottom section 6 at the lower end and the upper middle section 7 and the lower middle section 8 between the riser section 5 and the bottom section 6 . Sand mold bottom section 6 and upper middle section 7 and lower middle section 8 all comprise the back sand layer 9 of outer layer and the molding sand layer 10 of inner layer, and back sand layer 9 is made of the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com