Preparation method of controlled fluorescent graphene quantum dot

A graphene quantum dot and fluorescence technology, which is applied in chemical instruments and methods, nano-optics, luminescent materials, etc., can solve the problems of inability to achieve precise control of graphene quantum dots, troublesome operations, and complicated steps, so as to avoid the mixing of impurities. , The effect of uniform distribution and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 0.0150g of graphite oxide and add 20mL of ultrapure water. Sonicate for 30min, then add 5mL of hydrogen peroxide (30%), add 125mL of ultrapure water, and then irradiate under high-pressure mercury vapor arc lamp. A sample is taken before irradiation, and a sample is taken at the irradiation time of 5min, 10min, 15min, 20min, 25min, 30min, 45min, and 60min. This series of solutions is the prepared graphene quantum dots.

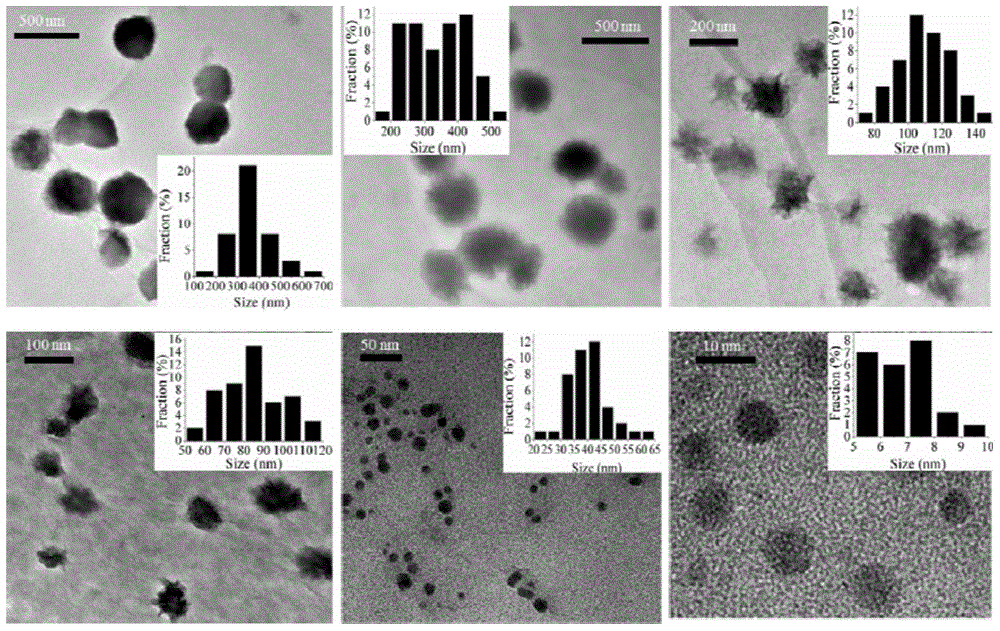

[0033] Such as figure 2 as shown, figure 2 A, B, C, D, E, and F in A, B, C, D, E, and F indicate that the radiation time is 5min, 10min, 15min, 20min, 25min, and 30min; when the radiation time is 5min, the particle size of GQDs is still relatively large; when the radiation time is prolonged At 30min, the diameter of GQDs is only 5nm, and the particle size distribution is uniform.

Embodiment 2

[0035] Weigh 0.0150g of graphite oxide and add 20mL of ultrapure water. Sonicate for 30min, then add hydrogen peroxide (30%) 25mL, add water 105mL, and then irradiate under high-pressure mercury vapor arc lamp. A sample is taken before irradiation, and a sample is taken at the irradiation time of 5min, 10min, 15min, 20min, 25min, 30min, 45min, and 60min. This series of solutions is the prepared graphene quantum dots.

Embodiment 3

[0037] Weigh 0.0150g of graphite oxide and add 20mL of ultrapure water. Sonicate for 30min, then add hydrogen peroxide (30%) 50mL, add water 80mL, and then irradiate under high-pressure mercury vapor arc lamp. A sample is taken before irradiation, and a sample is taken at the irradiation time of 5min, 10min, 15min, 20min, 25min, 30min, 45min, and 60min. This series of solutions is the prepared graphene quantum dots.

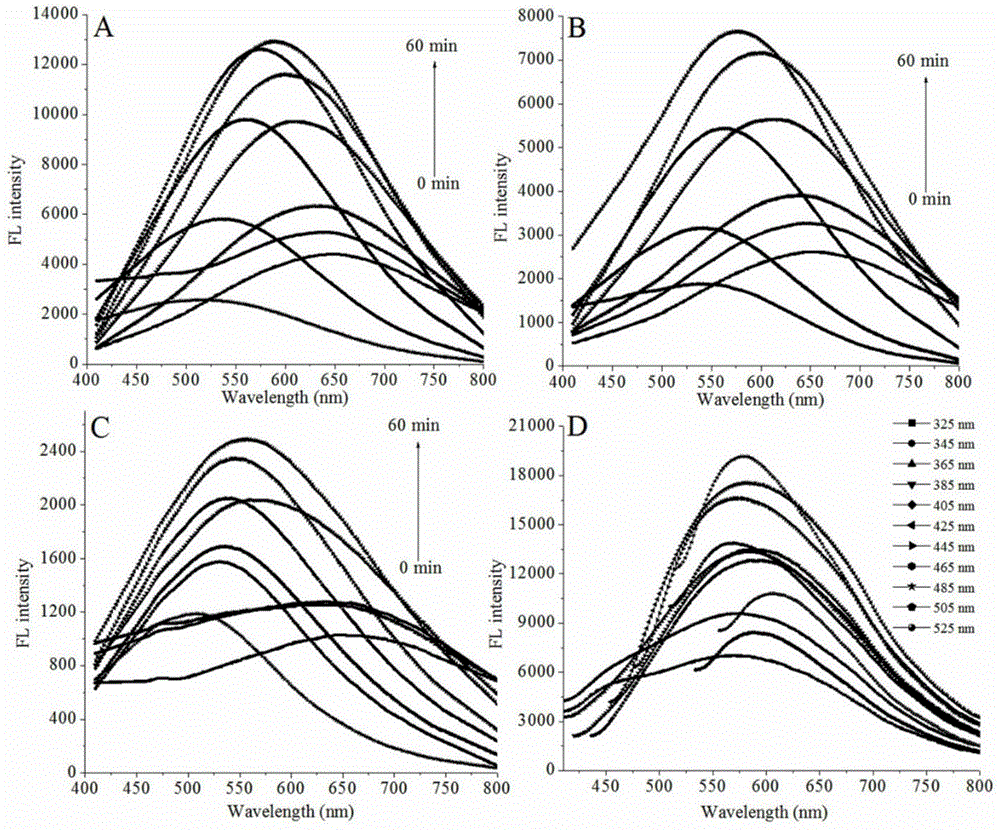

[0038] Such as image 3 as shown, image 3 Among them, A, B, and C are respectively the fluorescence spectrum diagrams of the graphene quantum dots prepared in Examples 1, 2, and 3; it can be seen that the GQDs obtained under different radiation times generally have blue shifts in their fluorescence maximum wavelengths. When the excitation wavelength When both were at 370nm, the maximum emission wavelength of GQDs moved from 650nm (0min) to 500nm (60min); the fluorescence intensity was the strongest when the irradiation time was 30min, and the maximum emission ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com