Preparation method of small-grain SAPO-34 molecular sieve

A SAPO-34 and molecular sieve technology, applied in the chemical field, can solve the problems of high cost and difficult industrial scale-up of the preparation process, and achieve the effects of easy operation, regular crystal form and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

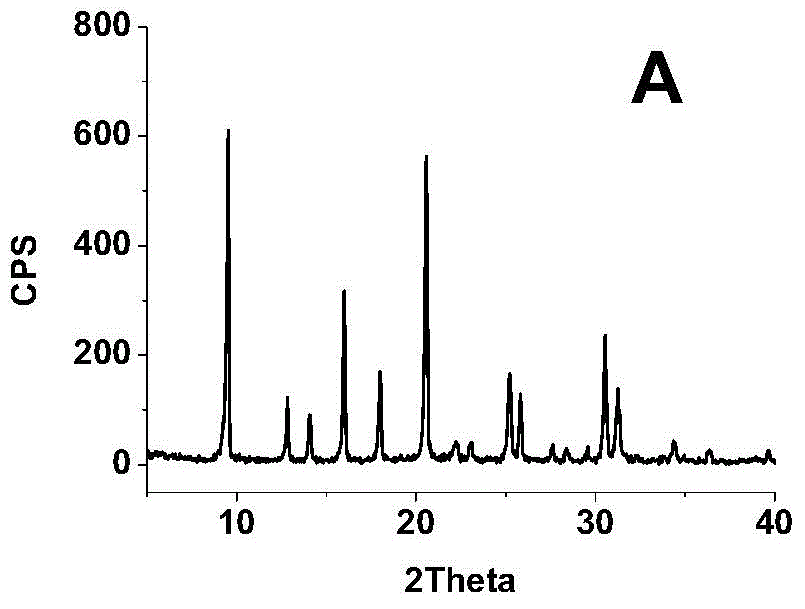

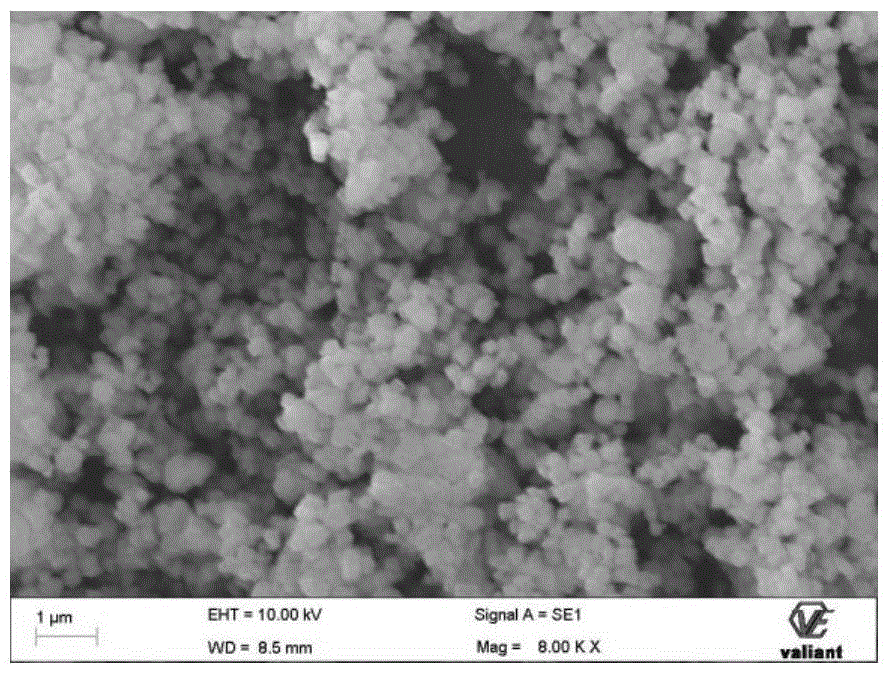

[0034] Under stirring at room temperature, 231.3g of aluminum isopropoxide (Al 2 o 3 Content is 26.3%) drop into 682g deionized water, slowly add 137.4g orthophosphoric acid (H 3 PO 4 Content is 85%), after stirring for 2h, add 71.4g silica sol (SiO 2 content is 30%), 266.4g triethylamine, 81.6gTMAmOH solution (TMAmOH content is 25%) and 51.3g n-hexane, after stirring for 3h, a uniform gel is formed; subsequently the gel is transferred to a 2L crystallization kettle, at 120rpm Crystallize at 180°C for 48 hours while stirring. After the crystallization is completed, the mixed solution is obtained, and the mixed solution is filtered to obtain a filter cake. While filtering, the filter cake is washed with deionized water until the pH value of the filtrate is less than 8, dried at 80-120°C for 3-8 hours, 550-600 Roasting at ℃ for 5-6 hours, the target product was obtained, which was named as A. After XRD and SEM characterization tests, it is found that product A has character...

Embodiment 2

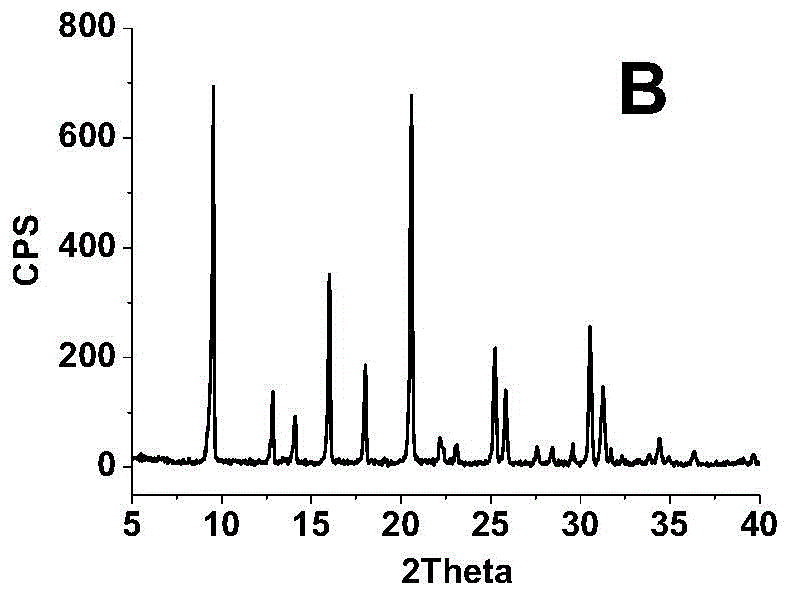

[0036] Under stirring at room temperature, 105.8g of pseudo-boehmite (Al 2 o 3 Content is 76.5%) drop into 884.8g deionized water, add 183.0g orthophosphoric acid (H 3 PO 4 Content is 85%), after stirring for 2h, add 95.2g silica sol (SiO 2 content is 30%), 355.2g triethylamine and 54.5gTMAmOH solution (TMAmOH content is 25%), after stirring for 3h, a uniform gel is formed; then the gel is transferred to a 2L crystallization tank, and stirred at 120rpm at 190°C Heat preservation and crystallization for 48h. After the crystallization is completed, filter the mixed solution to obtain a filter cake. While filtering, wash the filter cake with deionized water until the pH value of the filtrate is less than 8. Dry at 80-120°C for 3-8 hours, 550-600 Roasting at ℃ for 5-6 hours, the target product was obtained, which was named as B. After XRD and SEM characterization tests, it is found that product B has the characteristic diffraction peaks of CHA, such as image 3 As shown, the...

Embodiment 3

[0038] Under stirring at room temperature, 96.8g of pseudo-boehmite (Al 2 o 3 Content is 76.5%) drop into 813g deionized water, add 168.3g orthophosphoric acid (H 3 PO 4 Content is 85%), after stirring for 2h, add 86.9g silica sol (SiO 2 Content is 30%), 216.7g triethylamine, 49.9gTMAmOH solution (TMAmOH content is 25%) and 67.1g toluene, after stirring for 3h, a homogeneous gel is formed; then the gel is transferred to a 2L crystallization kettle, stirred at 120rpm Under the condition of 200 ℃ heat preservation and crystallization for 48h. After the crystallization is completed, the mixed solution is obtained, and the mixed solution is filtered to obtain a filter cake. While filtering, the filter cake is washed with deionized water until the pH value of the filtrate is less than 8, dried at 80-120°C for 3-8 hours, 550-600 Roasting at ℃ for 5-6 hours, the target product was obtained, which was named as C. After XRD and SEM characterization tests, it was found that product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com