Reinforcement method of aluminosilicate glass

A technology of aluminosilicate glass and strengthening treatment, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems that the exchange layer cannot reach the bending strength, thin glass is deformed, and the glass surface is easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~42

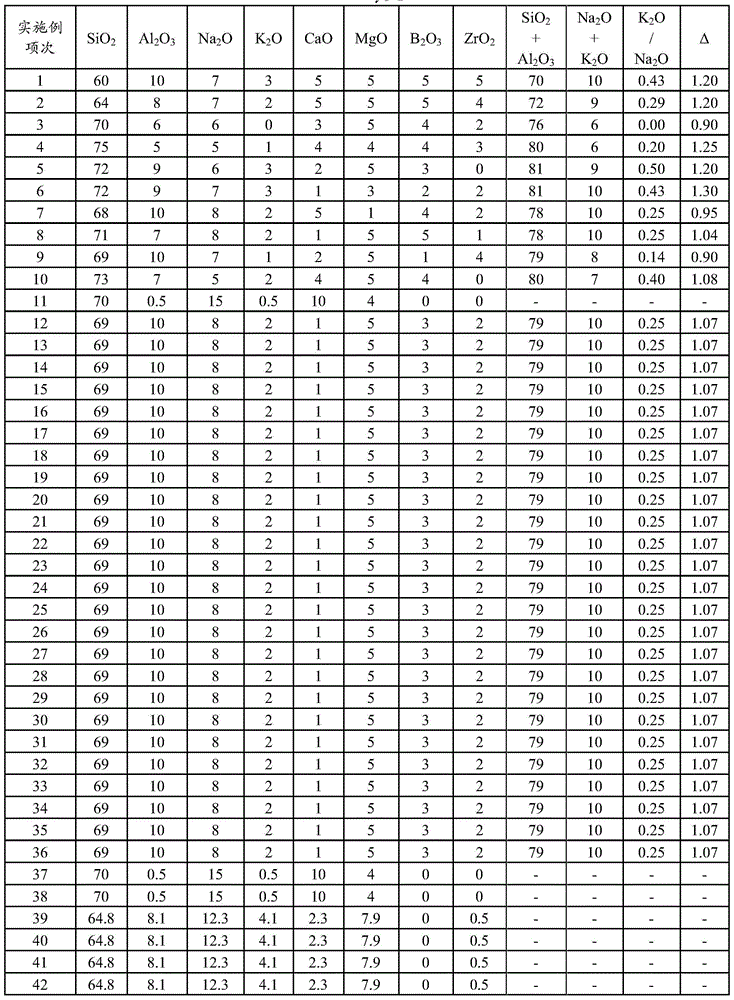

[0093] The composition of the aluminosilicate glass in Examples 1-42 is shown in Table 1. The numerical value corresponding to each raw material in Table 1 is the molar percentage of the raw material.

[0094] Table 1

[0095]

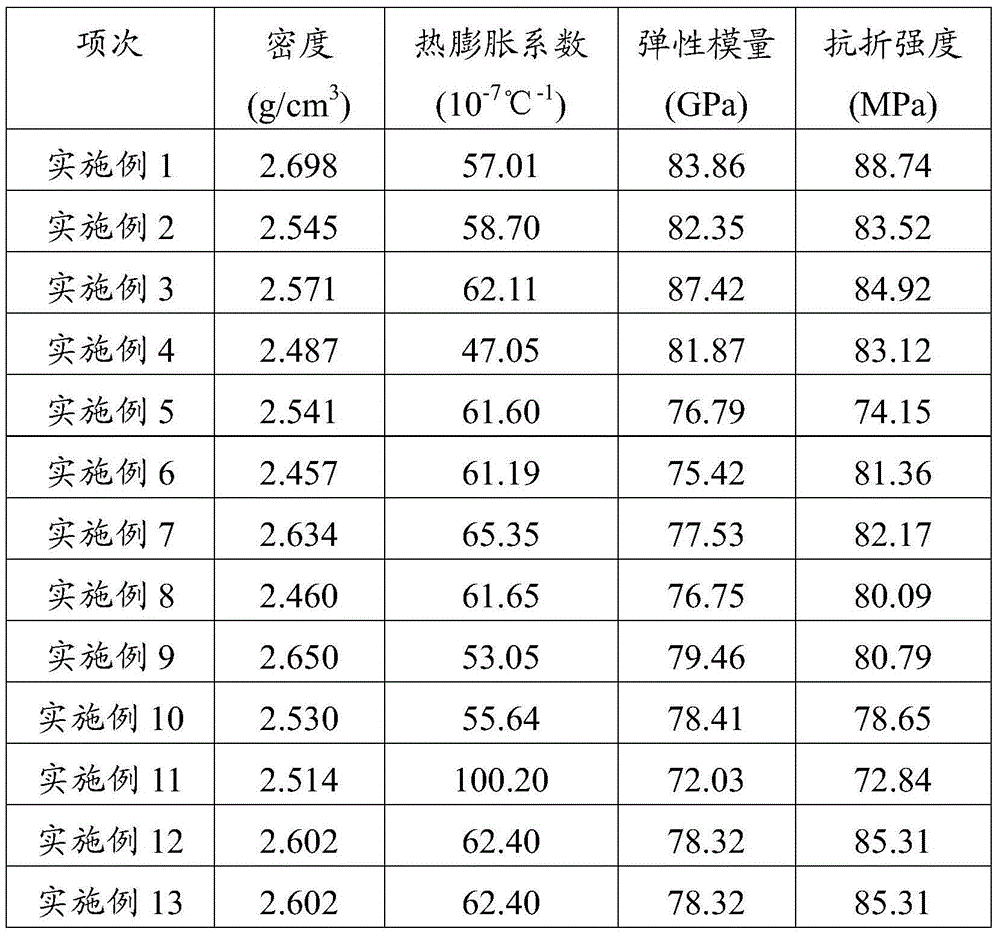

[0096] When preparing the aluminosilicate glass of Examples 1-42, weigh the raw materials according to the ratio of each raw material in Table 1, mix them thoroughly, put them into a platinum crucible, and put them into a resistance heating electric furnace at 1550°C for 5 hours melting and clarification. Pour the molten glass into a mold to form it, heat it at 580°C for 30 minutes for annealing, and then cool it to room temperature with the furnace to obtain a glass block. The glass blocks were made into standard specimens to test the density, coefficient of thermal expansion, modulus of elasticity and flexural strength. The relevant data are shown in Table 2.

[0097] Wherein, the density is measured according to GB / T5432-2008 standard.

[009...

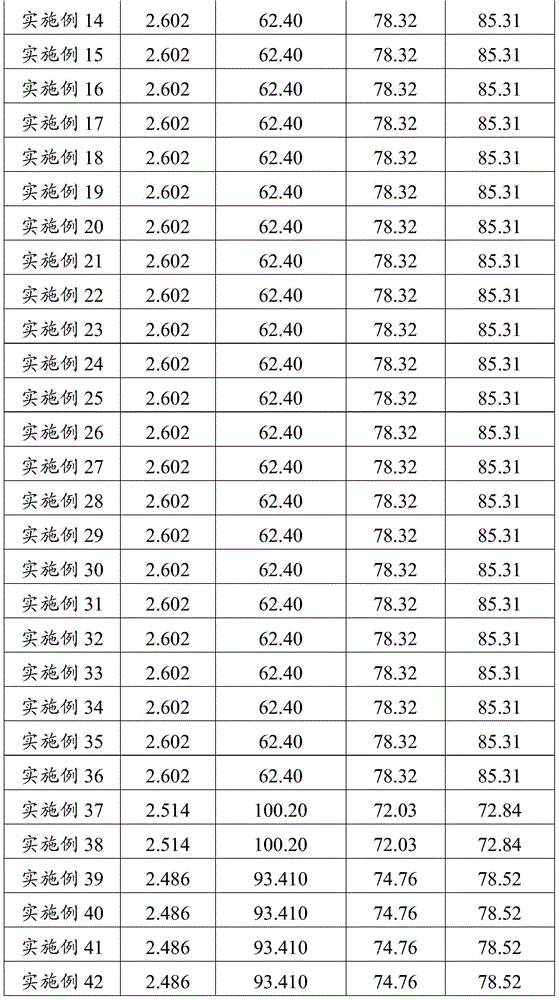

Embodiment 11

[0121] The glass in Example 11 is a typical soda-lime-silica glass, since it does not contain Al substantially 2 o 3 , so the material of the crystallization layer obtained after ion exchange is lithium silicate. It can be seen from the table that its strengthening effect is poor.

[0122] In Examples 12-36, aluminosilicate glass with the same composition was used for strengthening under different spraying process parameters. Among them, pure LiCl is used for spraying in Examples 12-31, and the ion exchange time and ion exchange temperature are different. The results show that ion exchange can be carried out at 650 ° C to 825 ° C for 3 minutes to 15 minutes to obtain a crystallized layer , and the more suitable ion exchange temperature is 800°C, and the more suitable ion exchange time is 10min. It can be seen from Examples 26 and 32-36 that when the composition of the strengthening treatment agent is 85%wtLiCl+15%wtNaCl, the bending strength and light transmittance of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com